Tussah silk adhesion preventive carding device and carding method

A tussah silk and silk technology, which is applied in liquid/gas/steam yarn/filament processing, silk reeling, and thin material processing, etc. It can solve the problems of silk sticking together, insufficient infiltration of medicinal liquid, and affecting silk quality, etc. , to achieve the effects of uniform and fast soaking, clean and fast cleaning, and simplified processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

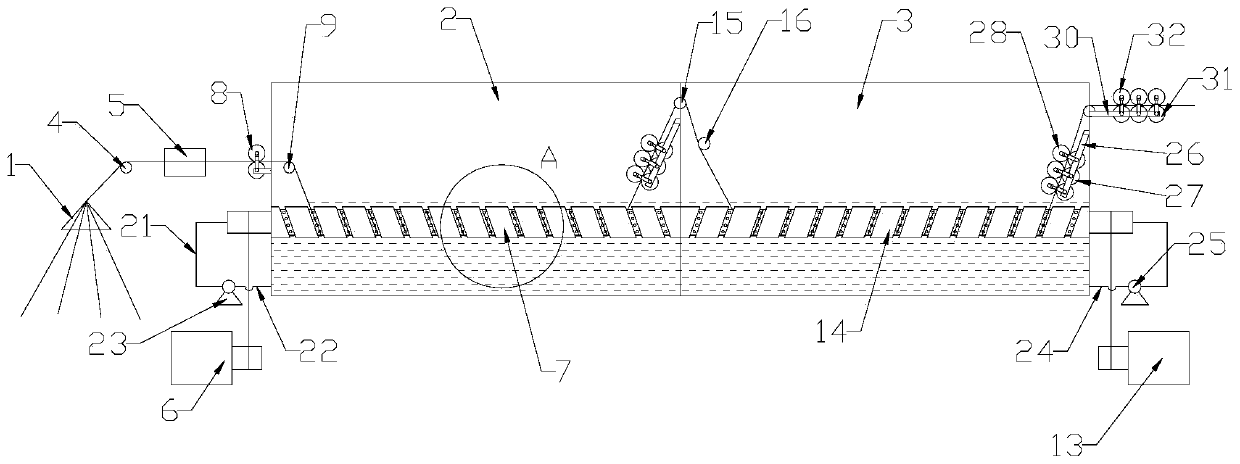

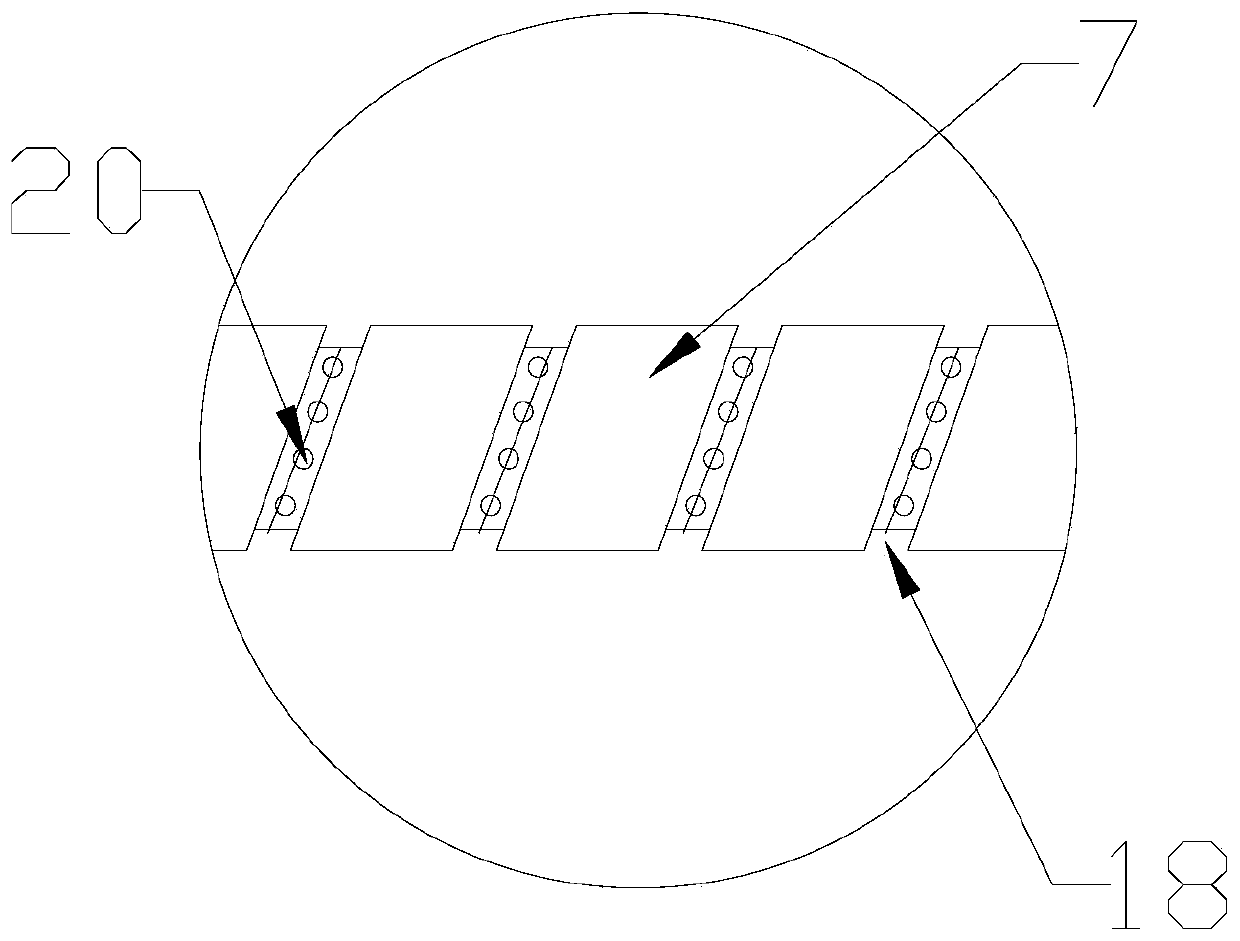

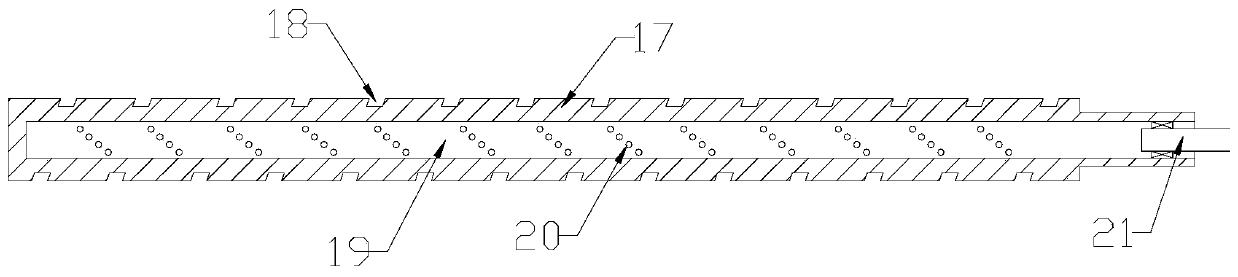

[0034] Such as figure 1 As shown, a device for preventing tussah silk from sticking and combing includes a thread collector 1, a soaking pool 2 and a cleaning pool 3, and a first steering wheel 4 and a drying device 5 are arranged between the thread collecting device 1 and the soaking pool 2 , the drying device 5 is an infrared dryer, and a soaking shaft 7 driven by a first motor 6 is arranged horizontally in the soaking pool 2. One end of the soaking shaft 7 is connected to one side of the soaking pool 2 through a bearing, and the other end is rotated through the soaking pool 2 through a bearing. The other side of the pool 2 is connected to the first motor 6 through a belt drive.

[0035] A wire feeding positioning mechanism is arranged above one end of the soaking shaft 7 close to the drying device 5 , and a first dehydration mechanism inclined upward is arranged above the other end. The wire feeding positioning mechanism includes a positioning piece 8 fixed on the outside ...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 6-8 As shown, both the first dehydration mechanism and the second dehydration mechanism include an upwardly inclined support frame 26, and a plurality of dehydration assemblies are installed on the support frame 26 along the conveying direction of silk, and the dehydration assembly includes a lower dehydration wheel installed on the support frame 26. 27, the side of the lower dehydration wheel 27 away from the support frame 26 is provided with an upper dehydration wheel 28, and the side walls of the upper dehydration wheel 28 and the lower dehydration wheel 27 are provided with a first arc-shaped groove 29 along the circumference, and the first arc groove 29 of a plurality of dehydration components The groove depth of an arc-shaped groove 29 decreases gradually along the conveying direction of silk, and the size of the opening end of the groove gradually increases along the conveying dir...

Embodiment 3

[0043] A carding method for preventing tussah silk from sticking, using the above-mentioned carding device, comprising the following steps:

[0044] (1) A plurality of cocoon threads are merged into silk through the thread collector 1, after the silk enters the drying device 5 through the first steering wheel 4 and is dried, then passes between the lower positioning wheel 10 and the upper positioning wheel 11, and the second regulating wheel The steering wheel 9 enters the soaking pool 2, and is wound on the soaking shaft 7 along the spiral groove 18 of the soaking shaft 7. The first motor 6 drives the soaking shaft 7 to rotate to carry out silk delivery. The soaking liquid is sent to the infusion chamber 19 of the soaking shaft 7, and is directly sprayed to the silk from the liquid outlet hole 20 for soaking, and the height of the soaking shaft 7 is lower than that of the soaking liquid;

[0045] (2) The silk enters between the lower dehydration wheel 27 and the lower dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com