A nozzle assembly for a miniature hydrogen flame ionization detector

A detector and hydrogen flame technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problem of unreliable detector sealing, and achieve good electrical insulation, simple sealing structure, high temperature resistance insulation and excellent sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

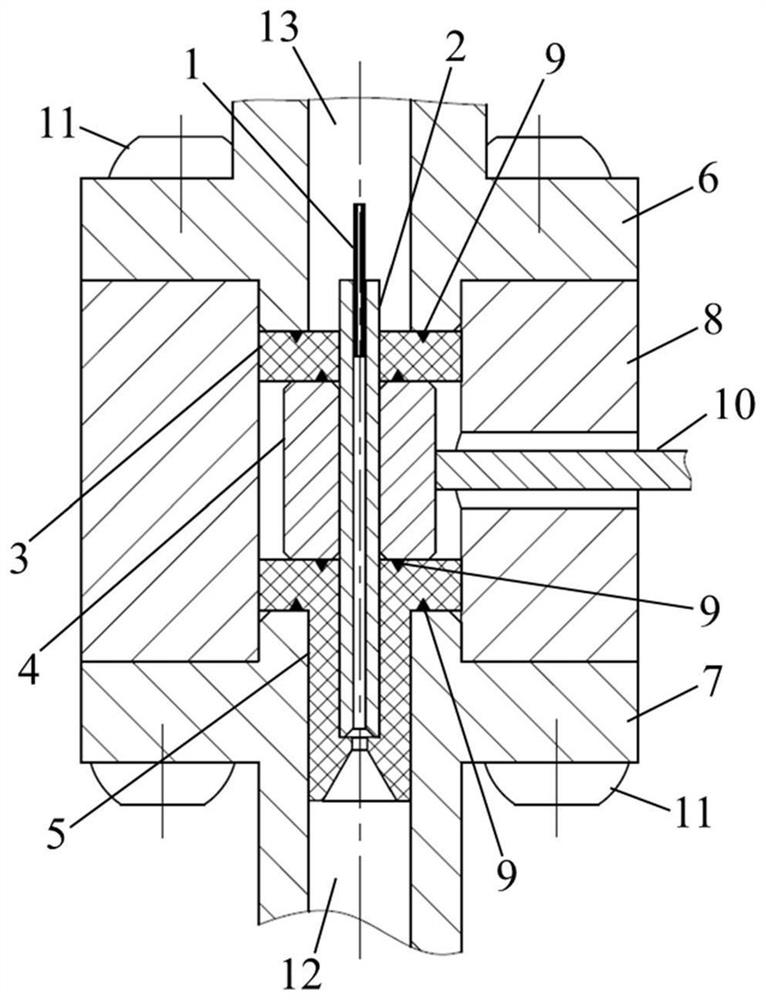

[0040] The μ-FID was developed using a new nozzle assembly, and the schematic diagram of the nozzle section is shown in figure 1 As shown, it consists of a nozzle 1, a guide tube 2, an upper seal 3, a sleeve 4, a lower seal 5, an upper pressure body 6, a lower pressure body 7, and a detector body 8. The material of the nozzle 1, the guide tube 2 and the casing 4 is stainless steel, and the material of the upper seal 3 and the lower seal 5 is high temperature resistant all-aromatic polyimide. The inner diameter of the nozzle 1 is 0.18mm, the outer diameter is 0.38mm, the length of the nozzle 1 extending into the guide pipe 2 is 3mm, and then it is fixed by brazing at the seam. The inner diameter of the guide tube 2 is 0.5 mm, the outer diameter is 1.6 mm, and the length is 17 mm; the guide tube 2 is 2 mm higher than the upper seal 3, inserted into the lower seal 5 to a depth of 7 mm, and is connected to the upper seal 3 and the lower seal 5 before extrusion Bore clearance fit....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com