Projection screen

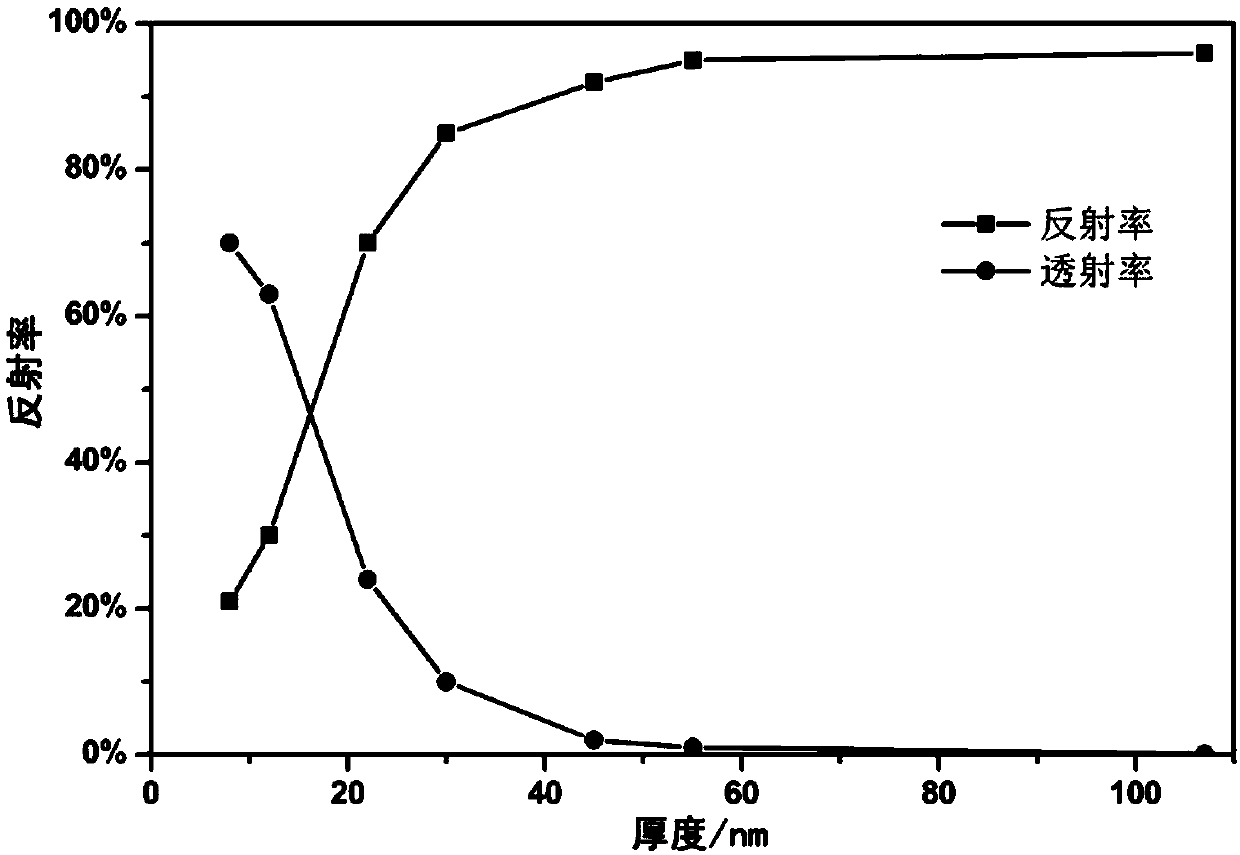

A projection screen and projection technology, used in optics, instruments, projection devices, etc., can solve the problems of complex production methods, high costs, and difficult processes, reducing process difficulties and screen costs, saving coating costs, and increasing transmission. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

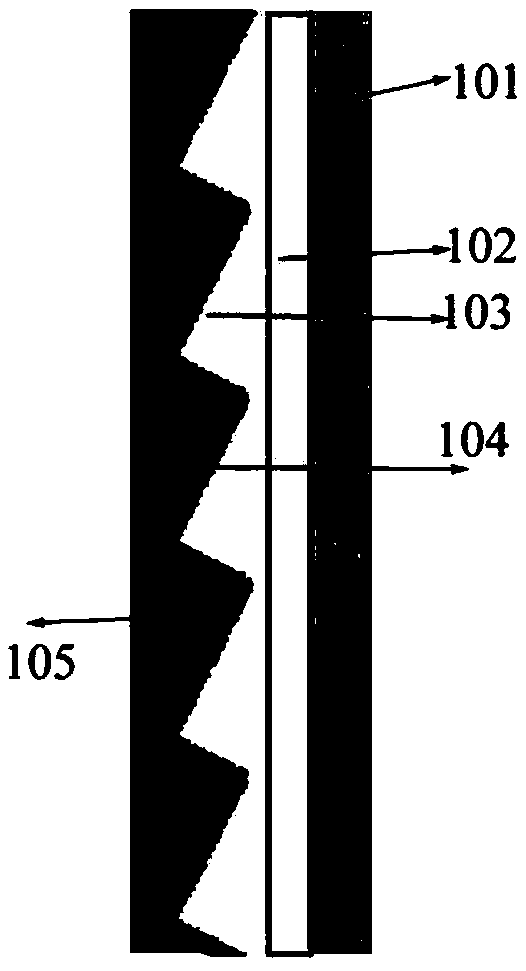

[0033] figure 2 It is a schematic structural diagram of a projection screen according to Embodiment 1 of the present invention. Such as figure 2 As shown, in this embodiment, the projection screen includes a diffusion layer 101 , a substrate layer 102 , a Fresnel structure layer 103 , a reflection layer 104 and a light absorption layer 105 arranged in sequence along the incident direction of the projection light.

[0034] Specifically, the diffusion layer 101 is a surface diffusion layer, one side of the surface diffusion layer has a microstructure (surface diffusion structure), and the surface diffusion layer has no microstructure and the substrate layer 102 (transparent PET) with a transparent For adhesive bonding, apply photosensitive adhesive (such as UV curable adhesive) on the side of the substrate layer 102 away from the diffusion layer 101, the thickness of the photosensitive adhesive is 10 μm-100 μm, preferably 20 μm-50 μm. The Fresnel structure is transferred to ...

Embodiment 2

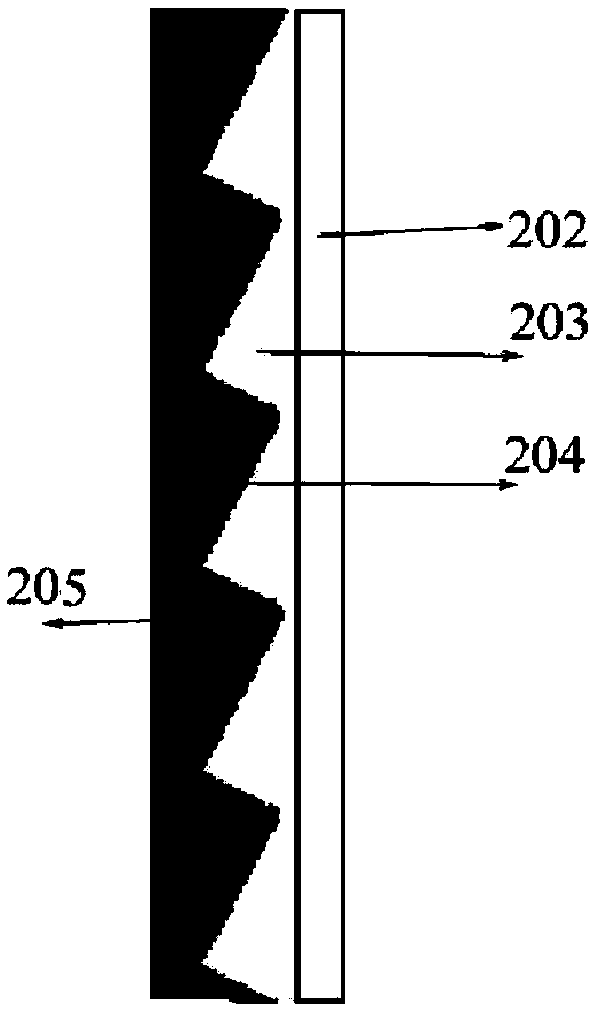

[0039] image 3 It is a schematic structural diagram of the projection screen in Embodiment 2 of the present invention. Such as image 3 As shown, the difference between this embodiment and the first embodiment is that the projection screen does not have a separate diffusion layer, but a surface diffusion structure is processed on the outer surface of the substrate layer 202, and the surface diffusion structure is used to realize the diffusion layer. function.

[0040] Specifically, in this embodiment, the projection screen includes a substrate layer 202 , a Fresnel structure layer 203 , a reflective layer 204 and a light-absorbing layer 205 sequentially arranged along the incident direction of the projection light.

[0041] When producing the above-mentioned projection screen, first set the surface diffusion structure on one side of the substrate layer 202, and then coat the photosensitive adhesive on the side of the substrate layer 202 without the surface diffusion structu...

Embodiment 3

[0044] Figure 4 It is a schematic structural diagram of a projection screen according to Embodiment 3 of the present invention. Such as Figure 4As shown, in this embodiment, the projection screen includes a reflection layer 304 , a Fresnel structure layer 303 , and a substrate layer 302 sequentially arranged along the incident direction of the projection light. The reflective layer 304 has a thickness of 12nm and a reflectivity of 25%.

[0045] In this embodiment, no light-absorbing layer is provided separately, and the base material layer 302 is black in order to absorb ambient light passing through the reflective layer.

[0046] Similar to the second embodiment, this embodiment does not provide a separate diffusion layer, but a surface diffusion structure is provided on the outer surface of the reflective layer 304, and the function of the diffusion layer is realized by using the surface diffusion structure.

[0047] It should be noted that the surface diffusion structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com