Method for preparing metal-semiconductor-metal (MSM) photo detector integrated with periodic light-limiting structure

A photodetector and periodic technology, which is applied in the field of visible light and infrared detection and imaging, can solve the problems of inconvenient large-scale integration and complicated process, and achieve the effects of facilitating large-scale integration, simplifying the preparation process, and improving the efficiency of light detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

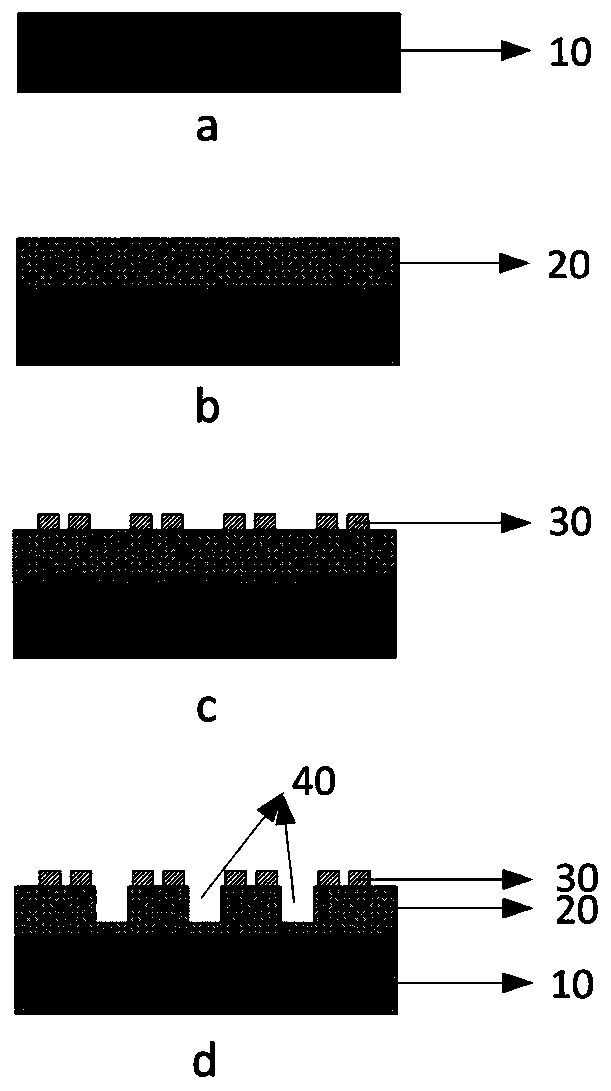

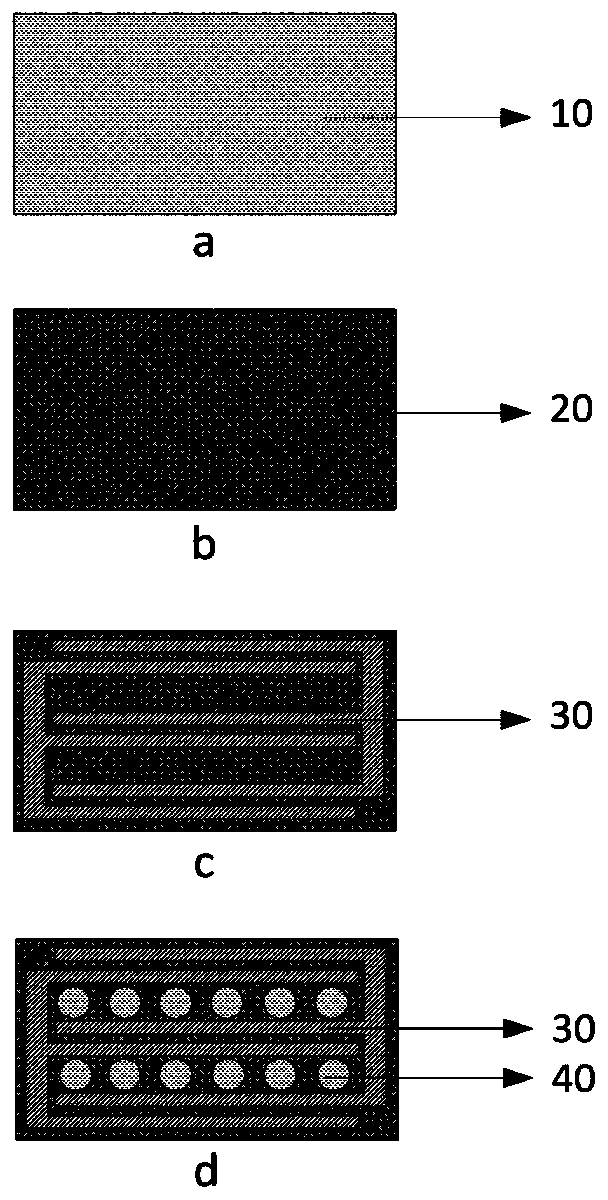

[0033] A preparation method of an MSM photodetector integrating a period-limited light structure, comprising the following steps:

[0034] Step 1: On the substrate substrate 10 such as figure 1 -a with figure 2 As shown in -a, the semiconductor thin film 20 is adhered to the surface of the substrate 10 by molecular beam epitaxy or metal organic chemical vapor deposition, as shown in figure 1 -b with figure 2 -b shown;

[0035] Step 2: On the semiconductor film 20, a metal film is prepared by magnetron sputtering and patterned to form several interdigital electrodes 30, such as figure 1 -c with figure 2 -c shown;

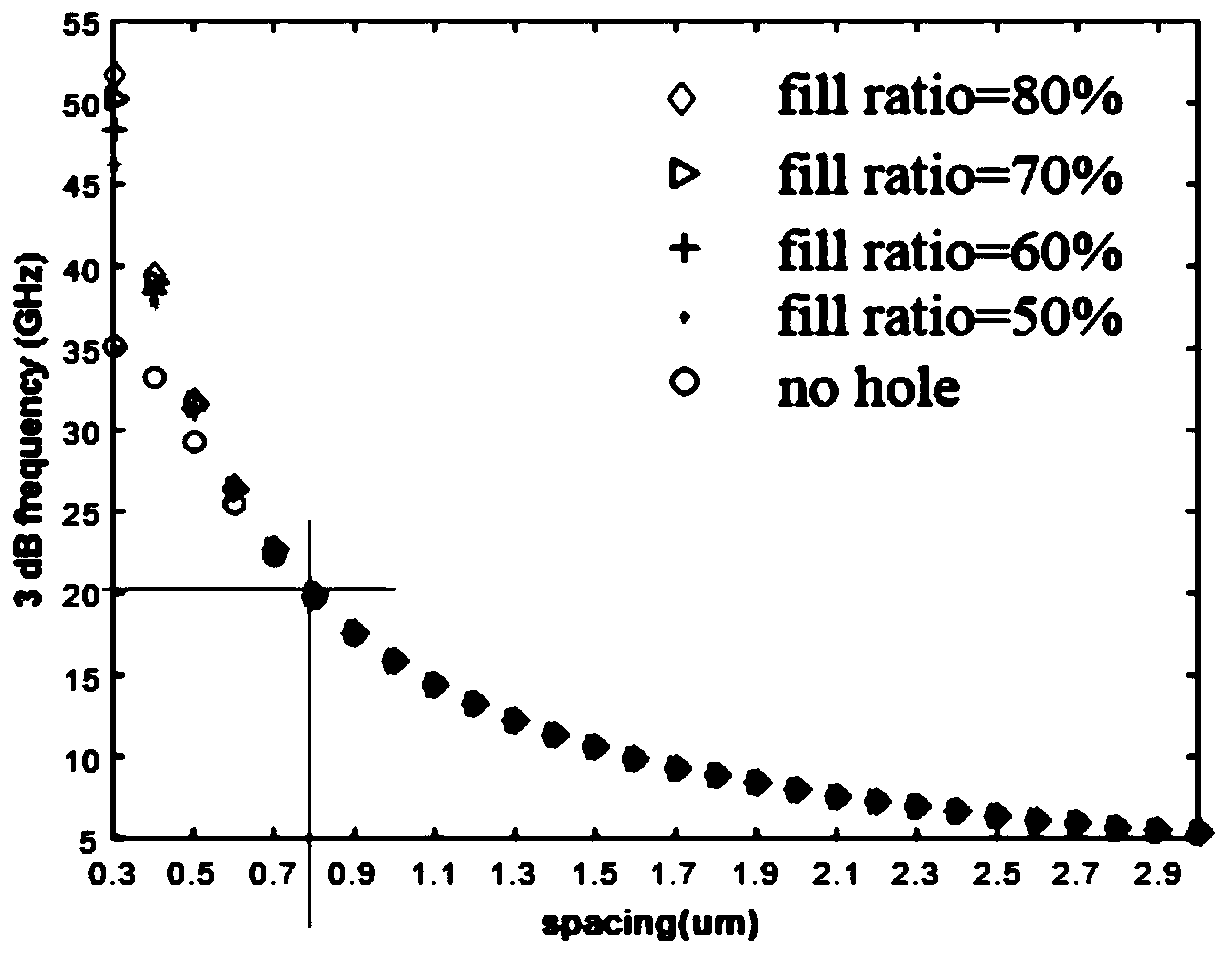

[0036] Step 3: Etching several periodic holes along the longitudinal direction of the semiconductor thin film 20 between each pair of interdigital electrodes 30 and forming a periodic light-limiting structure 40, each periodic hole does not penetrate the semiconductor thin film layer 20, such as figure 1 -d with figure 2 As shown in -d, the periodic ho...

Embodiment 1

[0041] like figure 1 Shown, a kind of preparation method of the MSM photodetector of integrated period-limited light structure, comprises the following steps:

[0042] Step 1: Select a silicon wafer with a silicon dioxide film on the surface as the device substrate. The thickness of the silicon wafer is 500 μm, and the thickness of the silicon dioxide layer is 3 μm. Clean the surface of the substrate to remove contamination, and dry the substrate at 200 ° C Bake for 30 minutes to remove moisture on the surface, such as figure 1 As shown in -a; a layer of silicon thin film is prepared on the substrate substrate by molecular beam epitaxy method, and the silicon thickness is 2.5 μm, such as figure 1 -b shown;

[0043] Step 2: Prepare a metal aluminum film on a silicon film by magnetron sputtering. The thickness of the film is 20nm. The patterned aluminum film forms interdigitated electrodes. The interdigitated electrodes are composed of multiple pairs of electrodes with a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com