Painless microneedle and preparation method thereof

A painless micro-needle technology, applied in the field of medical devices, can solve problems such as pain, limited therapeutic effect, and physical and mental impact of pain-sensitive patients, and achieve the effect of regulating qi and blood, magnetic force and drug penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the self-heating layer includes the following steps: under the protection of vacuum and nitrogen, the components are mixed into a paste, and then the paste is added to the synthetic resin film and pressed into a single-sided (with insulating layer) The contact surface) is a sheet with micropores.

[0051] The magnetic therapy material is composed of the following raw materials by weight: 15-20 parts of magnetic powder, 15 parts of dried ginger powder, 5 parts of sodium alginate and an appropriate amount of water.

[0052] The preparation method of the magnetic therapy layer includes the following steps: mixing magnetic powder and dried ginger powder, making a paste with warm water, then adding sodium alginate and mixing, wrapping with aluminized film, and pressing into a double-sided microporous The flakes are available.

[0053] The analgesic material is composed of the following raw materials by weight: 9 parts of Chuanwu, 9 parts of Caowu, 9 parts...

Embodiment 1

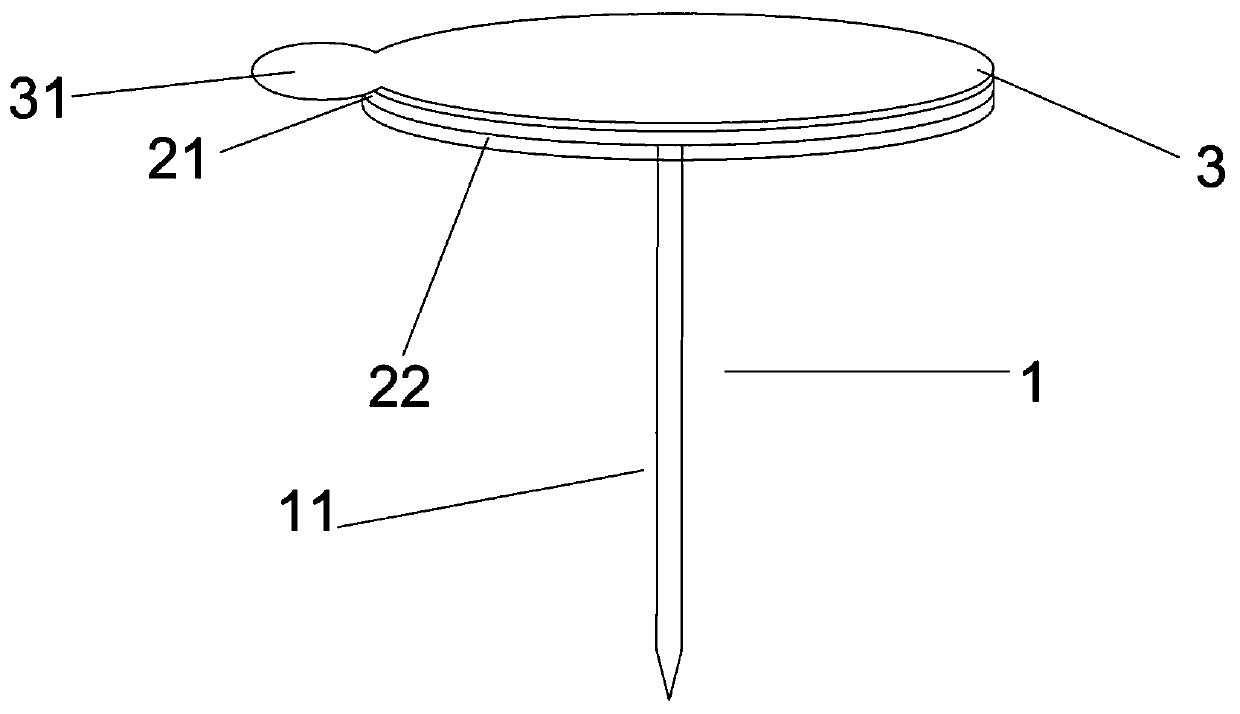

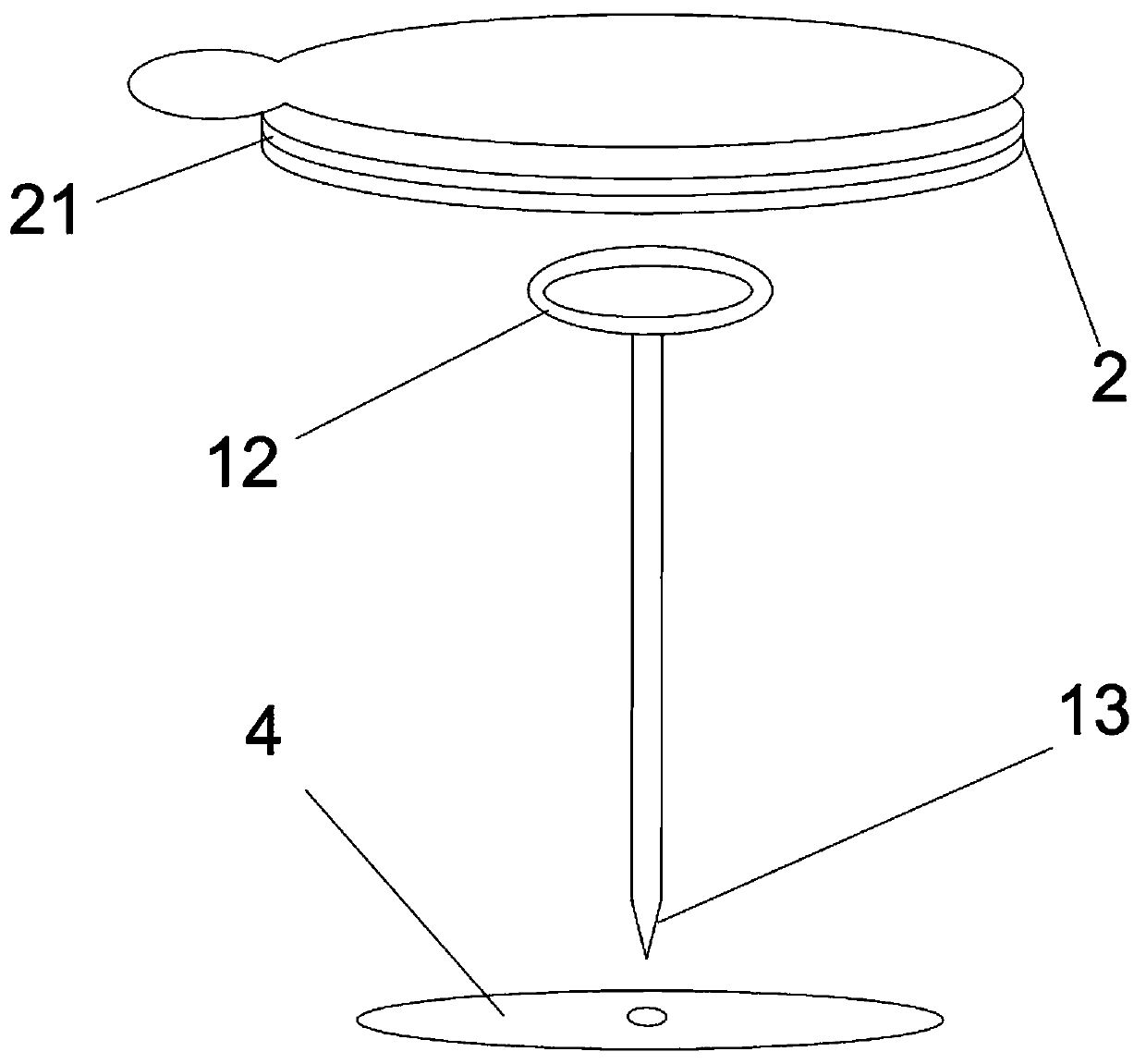

[0082] Such as image 3 As shown, a painless microneedle includes a needle body 1 and a functional layer 2; the needle body 1 includes a needle handle 12 and a needle tip 13; the oval needle handle 12 is connected to the functional layer 2; the functional layer 2 It includes a self-heating layer 21 and a magnetic treatment layer 22 arranged in sequence from top to bottom. The self-heating layer 21 is made of a sheet with micropores on one side by placing a self-heating material in a synthetic resin film. The treatment layer 22 is made by placing the magnetic treatment material in an aluminized film to make a thin sheet with 1-3mm micropores on both sides; the insulation layer 3 is made of plastic film material and is arranged on the uppermost end of the functional layer, on the insulation layer The tearing end 31 is provided. Then the insulating layer, the self-heating layer and the magnetic therapy layer are connected in sequence from top to bottom, wherein the insulating lay...

Embodiment 2

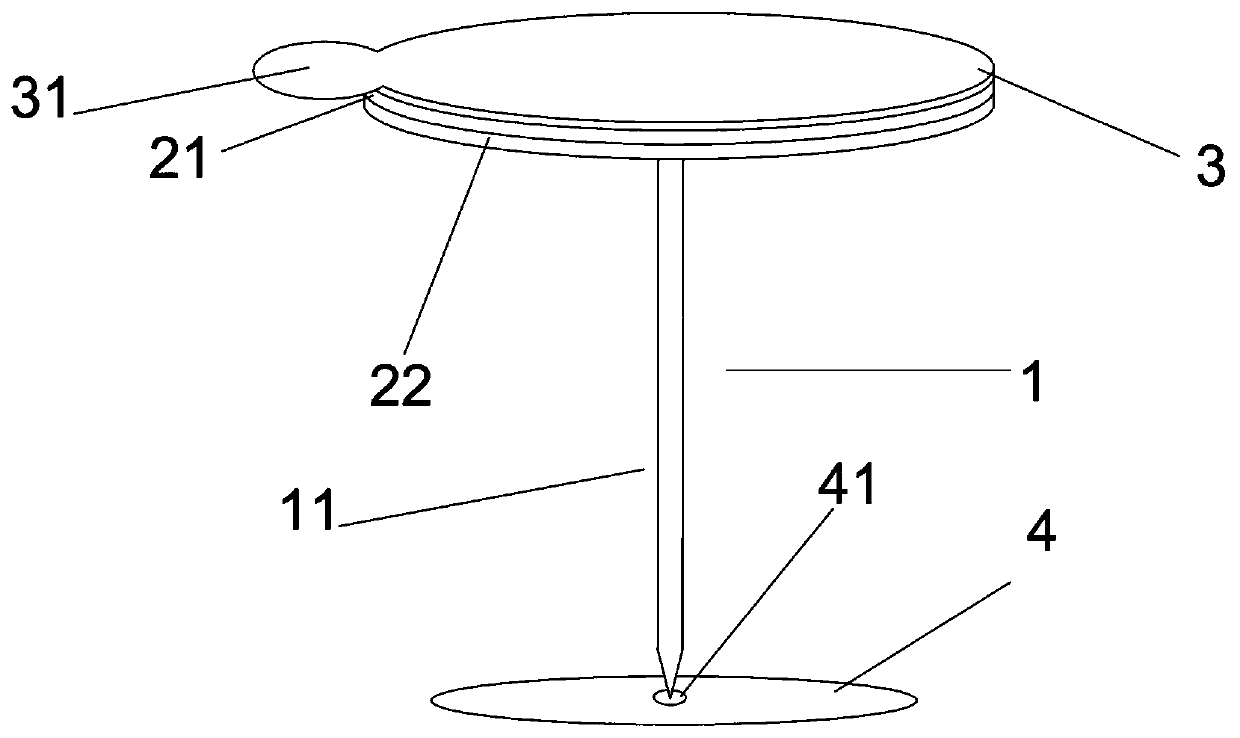

[0085] Such as figure 1 As shown, a painless microneedle includes a needle body 1, a functional layer 2 and an analgesic layer 4; the needle body 1 includes a needle handle 12 and a needle tip 13; the oval needle handle 12 is connected to the functional layer 2; The functional layer 2 includes a self-heating layer 21 and a magnetic therapy layer 22 arranged in order from top to bottom. The self-heating layer 21 is made of a sheet with holes in the upper layer by placing a self-heating material in a synthetic resin film. The magnetic therapy layer 22 is made by placing a magnetic therapy material in an aluminized film to make a thin sheet with micropores on both sides; the insulating layer 3 is made of plastic film and is arranged at the uppermost end of the functional layer, and is arranged on the insulating layer There is a tearing end 31; the analgesic layer 4 is prepared by placing analgesic material in an aluminized film to prepare a microporous film, and a hole matching the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com