Kitchen waste vacuum treatment system and working method thereof

A technology for kitchen waste and vacuum treatment, applied in special treatment targets, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as secondary pollution, prevent secondary pollution, avoid pipeline blockage, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

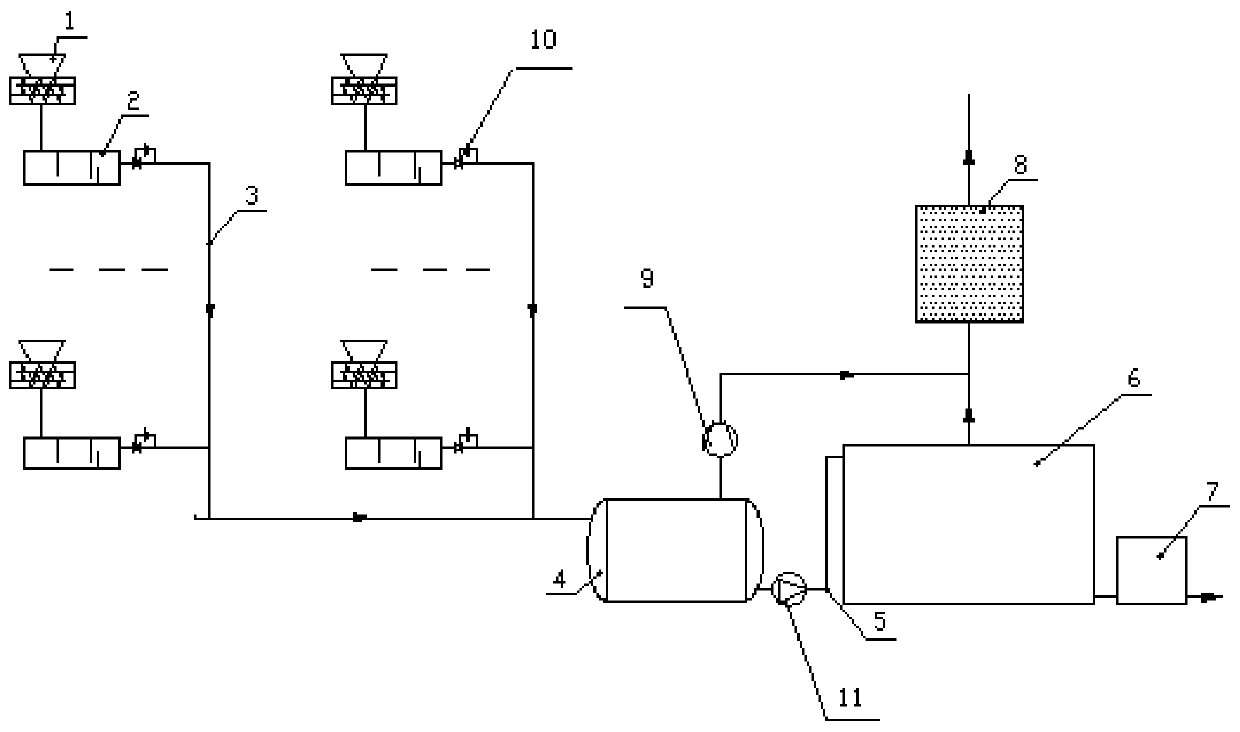

[0043] This embodiment discloses a working method of a vacuum treatment system for food waste. The vacuum pump works to evacuate the vacuum collection tank. When the pressure information collected by the pressure switch received by the controller reaches the set value, the vacuum pump stops working. Garbage sewage is poured into the garbage crushing device. The garbage crushing device crushes the solid waste carried in the sewage. The crushed garbage enters the grease trap along with the sewage through the water inlet of the grease trap. The grease trap separates the sewage from oil and water. The sewage liquid level in the grease trap rises to the first liquid level sensor. After the first liquid level sensor detects the sewage signal, it sends an instruction to the controller, and the controller controls the valve of the vacuum pipeline to open. Under the vacuum action of the vacuum collection tank, The sewage and solid waste in the grease trap enter the vacuum collection tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com