Process for producing light oil through second-stage conversion of biomass

A biomass and light oil technology, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the treatment of hydrocarbon oil, etc. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

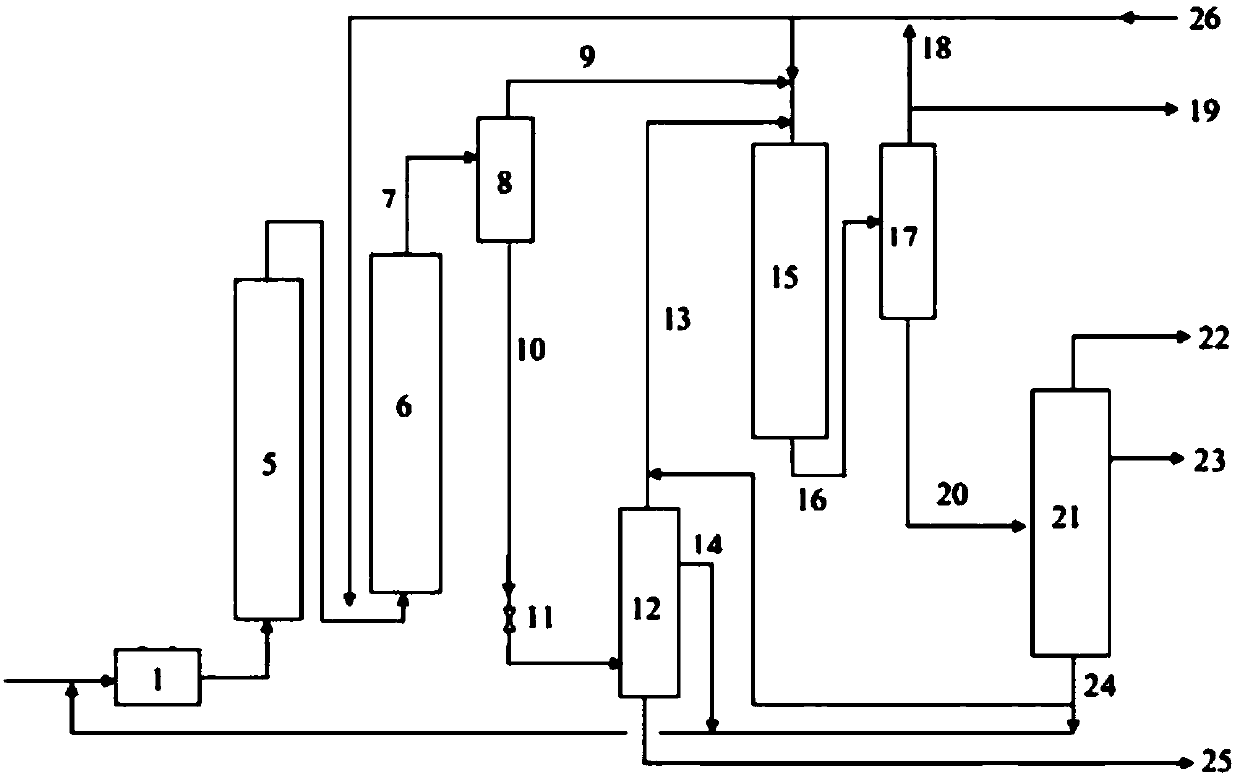

Method used

Image

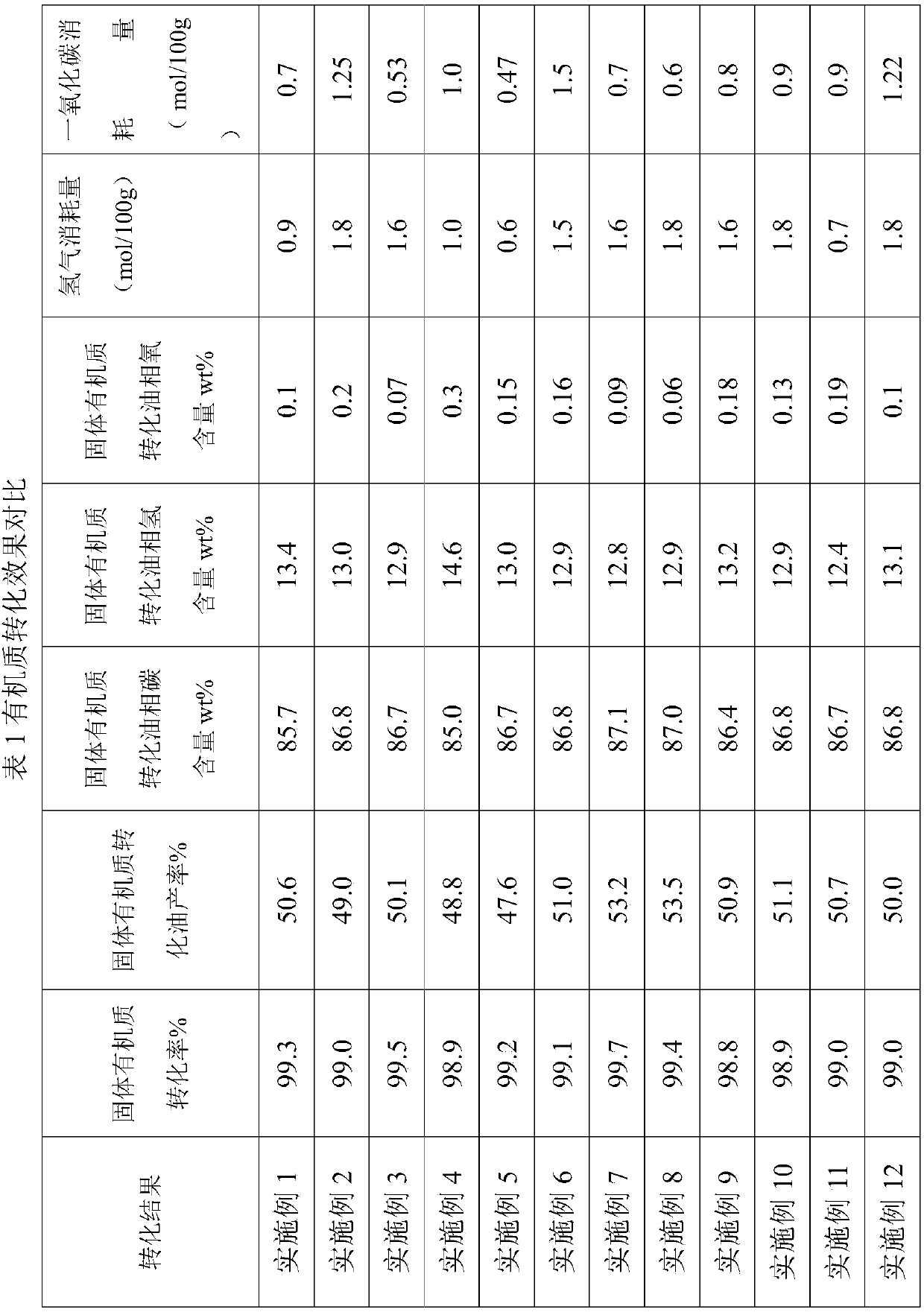

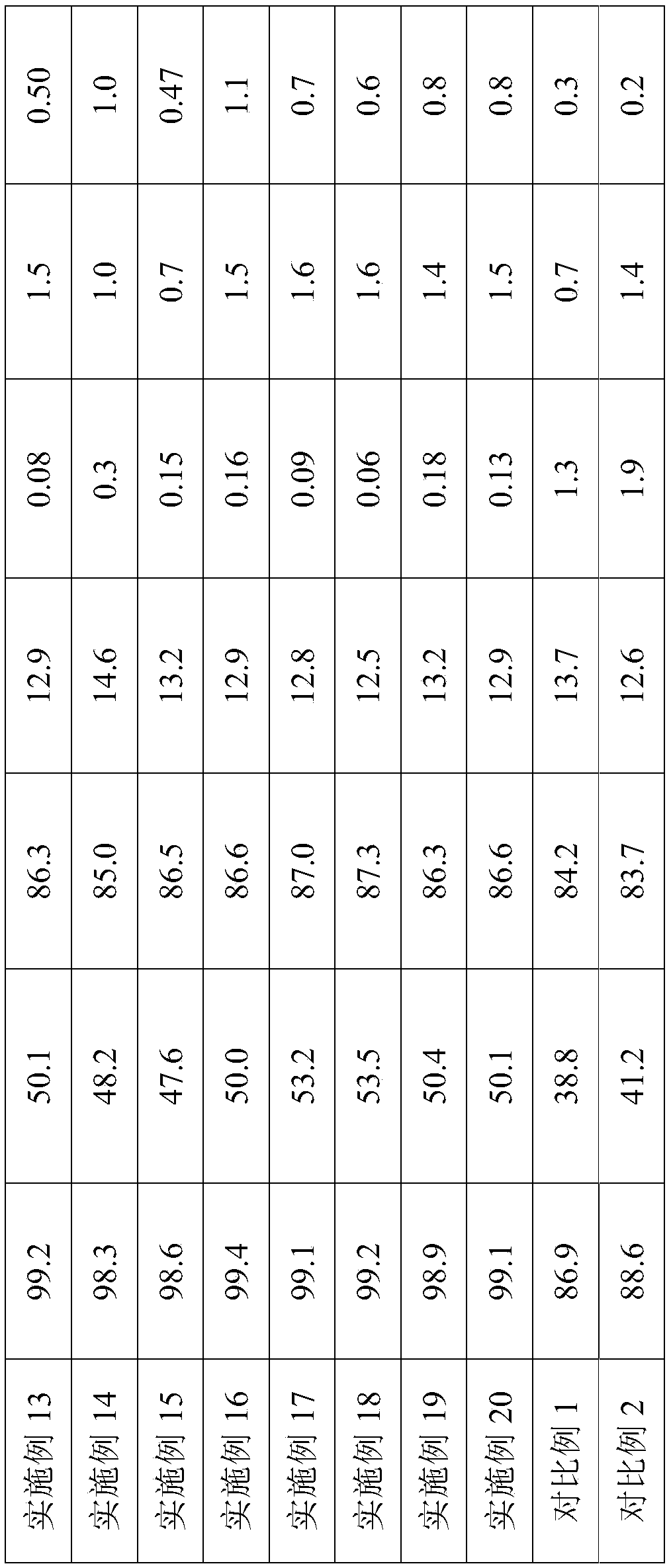

Examples

Embodiment 1

[0088] This embodiment provides a process for secondary conversion of biomass to produce light oil, comprising the following steps:

[0089] Preparation of biomass slurry:

[0090] collecting corn stalks, the water content of which is 5-20wt%, and then pulverizing them to a particle size of 0.2 μm-5 cm by using an ultrafine pulverizer;

[0091] Compress the crushed straw with a plodder, the compression pressure is 2.5MPa, the compression temperature is 45°C, and compressed to a true density of 1.0kg / m 3 ;

[0092] The compressed and molded straw is pulverized again with a jet mill, passed through a 100-mesh sieve to obtain straw powder, and 100 kg of straw powder is weighed and mixed with a catalyst to obtain a mixed powder;

[0093] Mix 80 kg of waste lubricating oil and mixed powder with 8 kg of water, and use a colloid mill for grinding and pulping. The grinding and pulping time is 15 minutes to obtain biomass slurry.

[0094] The catalyst added in the slurry is an iro...

Embodiment 2

[0111] This embodiment provides a process for secondary conversion of biomass to produce light oil, comprising the following steps:

[0112] Preparation of biomass slurry:

[0113] Collecting wheat straw, the water content of which is 10-20wt%, and then pulverizing it to a particle size of 0.2μm-5cm by using an ultrafine pulverizer;

[0114] Compress the crushed straw with a plodder, the compression pressure is 0.5MPa, the compression temperature is 60°C, and compressed to a true density of 0.75kg / m 3 ;

[0115] The compressed and molded straw is pulverized again with a jet mill, and passed through an 80-mesh sieve to obtain straw powder;

[0116] 100kg of washing oil, 100kg of straw powder, catalyst and 3kg of water were mixed, and a colloid mill was used for grinding and pulping. The grinding and pulping time was 8 minutes to obtain a biomass slurry.

[0117] The catalyst added in the slurry is an iron-based catalyst with a content of 1 wt%, and the average particle dia...

Embodiment 3

[0136] This embodiment provides a process for secondary conversion of biomass to produce light oil, comprising the following steps:

[0137] Preparation of biomass slurry:

[0138] Collect red algae, air-dry until its water content is lower than 20wt%, and crush to a particle size of 0.2 μm-5cm;

[0139] Compress the pulverized red algae into a tablet press with a compression pressure of 3MPa, a compression temperature of 40°C, and compress to a true density of 0.95kg / m 3 ;

[0140] The compressed red algae is pulverized again with a jet mill, and passed through a 100-mesh sieve to obtain red algae powder;

[0141] Take 40kg of pulverized red algae powder, 50kg of waste engine oil and 5kg of water, mix them, grind and make pulp for 12 minutes, and obtain biomass slurry.

[0142] The catalyst added in the slurry is an iron-based catalyst with a content of 1 wt%, and the average particle diameter of the added iron-based catalyst is 10 μm.

[0143] Iron catalyst:

[0144...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com