Schiff-base waste cooking oil derivative corrosion inhibitor and preparation method and application thereof

A technology of catering waste oil and Schiff base, applied in the field of industrial pickling process, can solve the problems of economic loss of national economy, corrosion of carbon steel materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

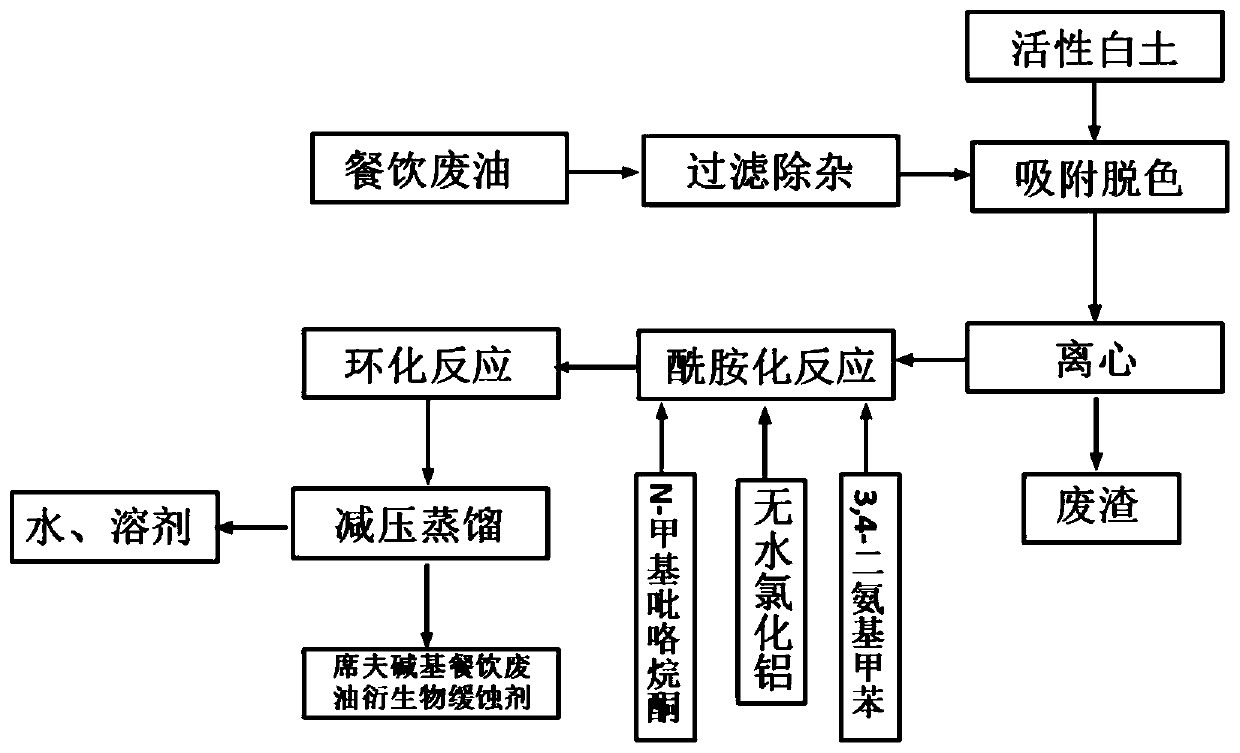

[0019] (1) Firstly, filter waste catering oil, then add activated clay with a mass fraction of 5%-10% to the waste oil and stir evenly, decolorize the waste oil, then centrifuge, and take the upper layer of oil;

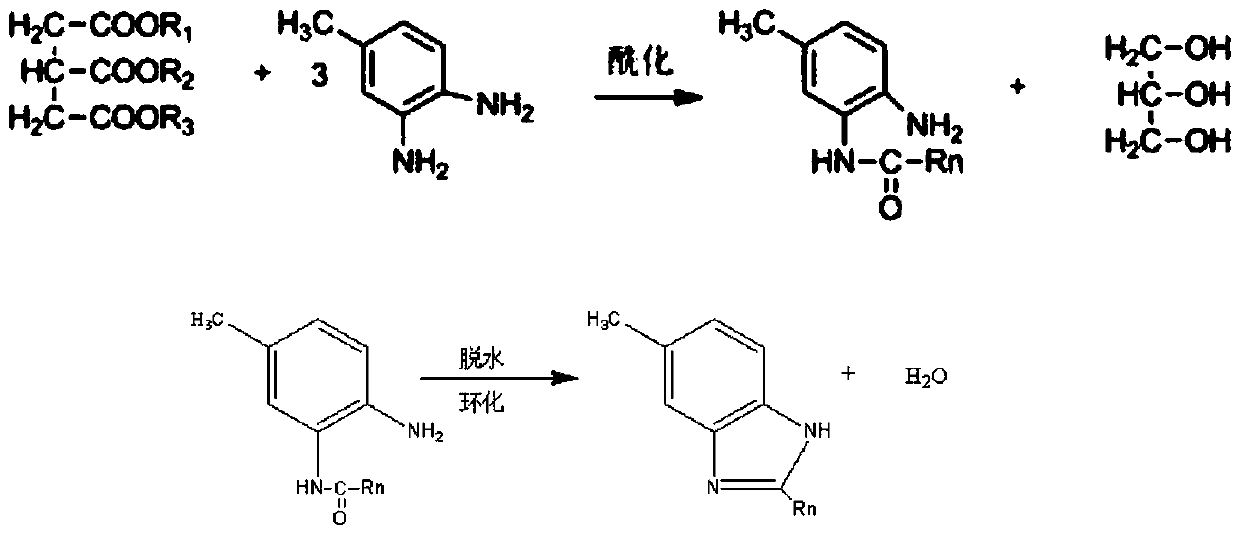

[0020] (2) According to the molar ratio of 1:3.4, weigh the catering waste oil and 3,4-diaminotoluene pretreated in step (1), put the weighed catering waste oil and 3,4-diaminotoluene into 100mL round-bottomed flask, then add 20mL N-methylpyrrolidone and 5% anhydrous aluminum chloride into the round-bottomed flask respectively, put the round-bottomed flask into a magnetic stirring oil bath, connect a spherical condenser, and pass Enter nitrogen protection, react at 150°C for 3 hours, then raise the temperature to 200°C, stop the reaction after reacting for 12 hours, and obtain a purple-red solution;

[0021] (3) Distill the purple-red solution obtained in step (2) under reduced pressure to remove the solvent, water, and glycerol, and finally obtain a viscous Schiff b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com