Heat dissipation system and method for fan engine room

A heat dissipation system and nacelle technology, applied in the monitoring of wind turbines, machines/engines, wind turbines, etc., can solve problems such as changes in viscosity-temperature characteristics→deterioration of lubrication characteristics, affecting the temperature of lubricating oil in gearboxes, and aggravating oil oxidation. Achieve the effects of improving safety and stability, accelerating air movement speed, and stabilizing air movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

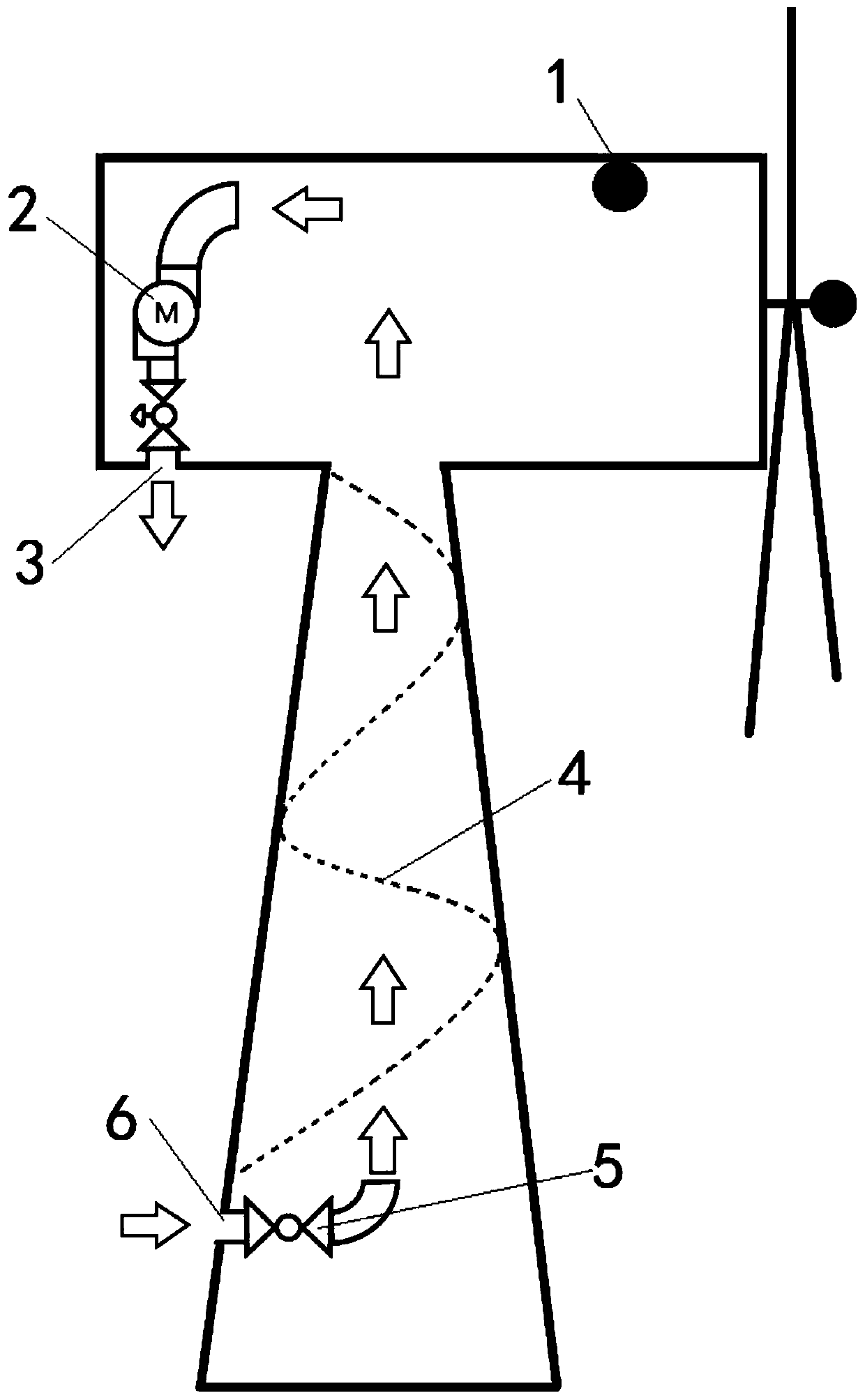

[0032] figure 1 It is the heat dissipation system of the fan cabin of the present invention, including a temperature measuring device 1, a top ventilation mechanism 2, a bottom ventilation mechanism 3, an air deflector 4 and a control system;

[0033] The temperature measuring device 1 and the top ventilation mechanism 2 are arranged in the cabin, and the temperature measuring device 1 is preferably arranged at the top of the cabin. An air outlet 5 is arranged on the shell of the nacelle, and the air outlet 5 is preferably arranged at the bottom of the shell of the nacelle. The air outlet 5 is located in the heat concentration area inside the nacelle, such as the area where parts that are prone to high temperature such as the gear box are located. The wall at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com