Steelmaking quantity distribution control method for steelmaking continuous casting planned material flow direction setting

A technology for steelmaking, continuous casting, and control methods, which is applied in computing, instrumentation, technical management, etc., and can solve problems such as difficulty in quantification and extensive manual setting methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

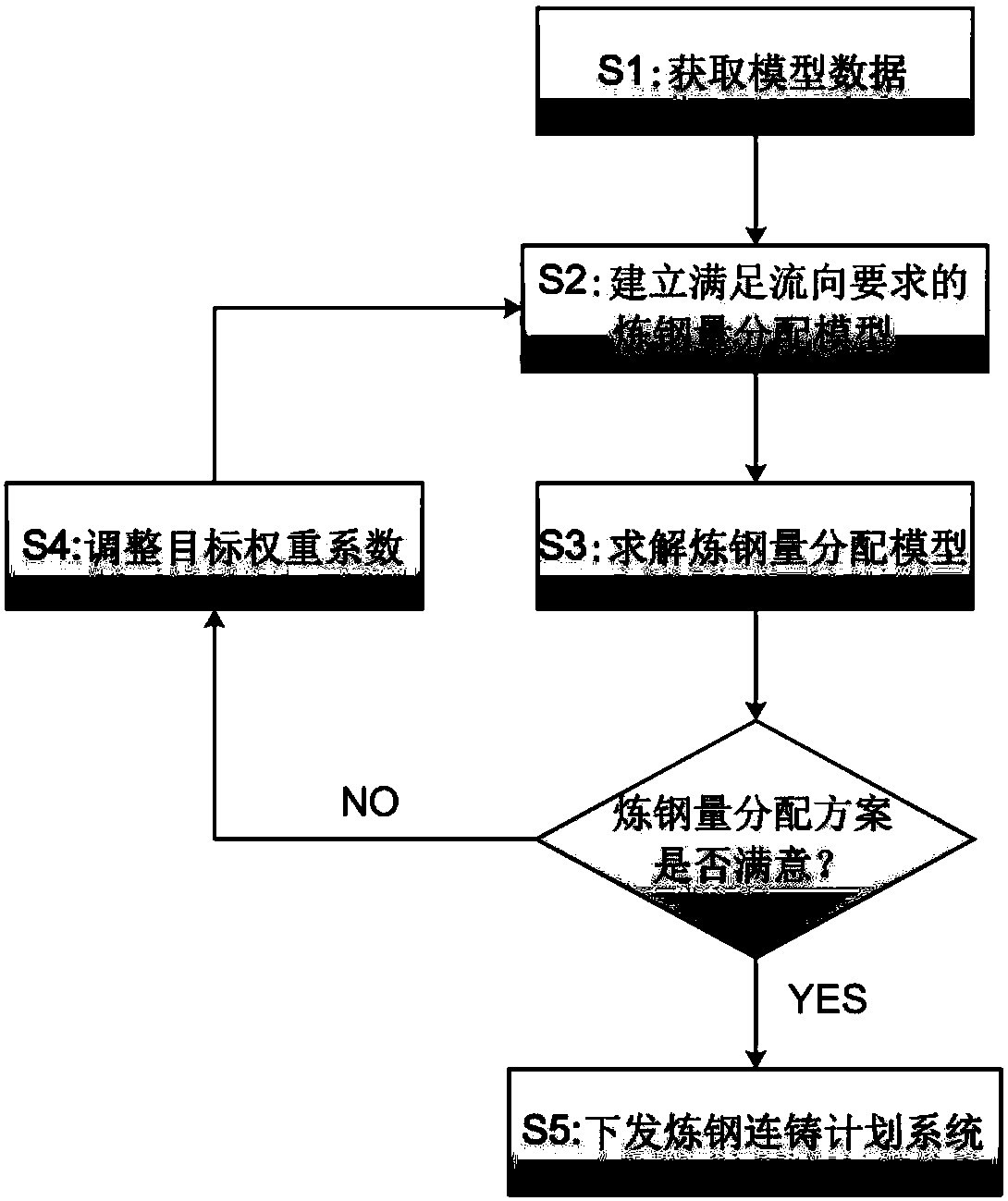

Method used

Image

Examples

Embodiment

[0069] Step 1. Get model parameters

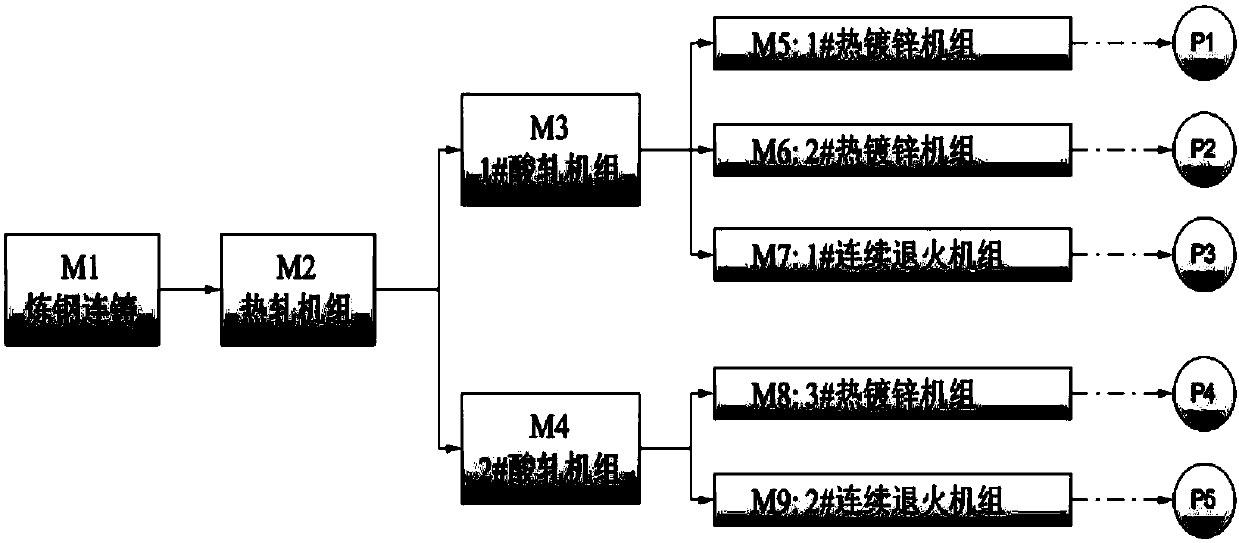

[0070] The unit production line structure of this embodiment is as follows figure 2 As shown, it consists of 1 steel-making continuous casting unit, 1 hot rolling unit, 2 pickling-rolling units, 3 hot-dip galvanizing units and 2 continuous annealing units. There are a total of 5 flow directions, respectively P1, P2, P3, P4, P5 indicate that, taking the flow direction of P1 as an example, the processing path corresponding to the flow direction of P1 is M1 (steel making and continuous casting) -> M2 (Hot Rolling Mill)-> M3 (1# pickling mill)-> M5 (1# hot-dip galvanizing unit). Correspondingly, the M5 unit is the finished unit in the direction of P1. The inventory in the direction of P1 refers to the inventory of the work in progress between the M1 and M5 units. The sum of the stocks of pickled coils, the rest of the flow is similar.

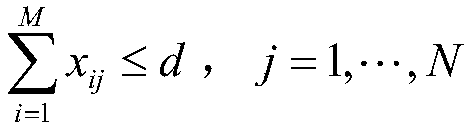

[0071] The calculation of the distribution of steel-making needs to obtain basic data such as the production ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com