Ultrathin multi-absorption-peak low-frequency sound absorber

A technology of absorption peak and sound absorber, which is applied in the direction of sounding equipment and instruments to achieve the effects of strong absorption, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

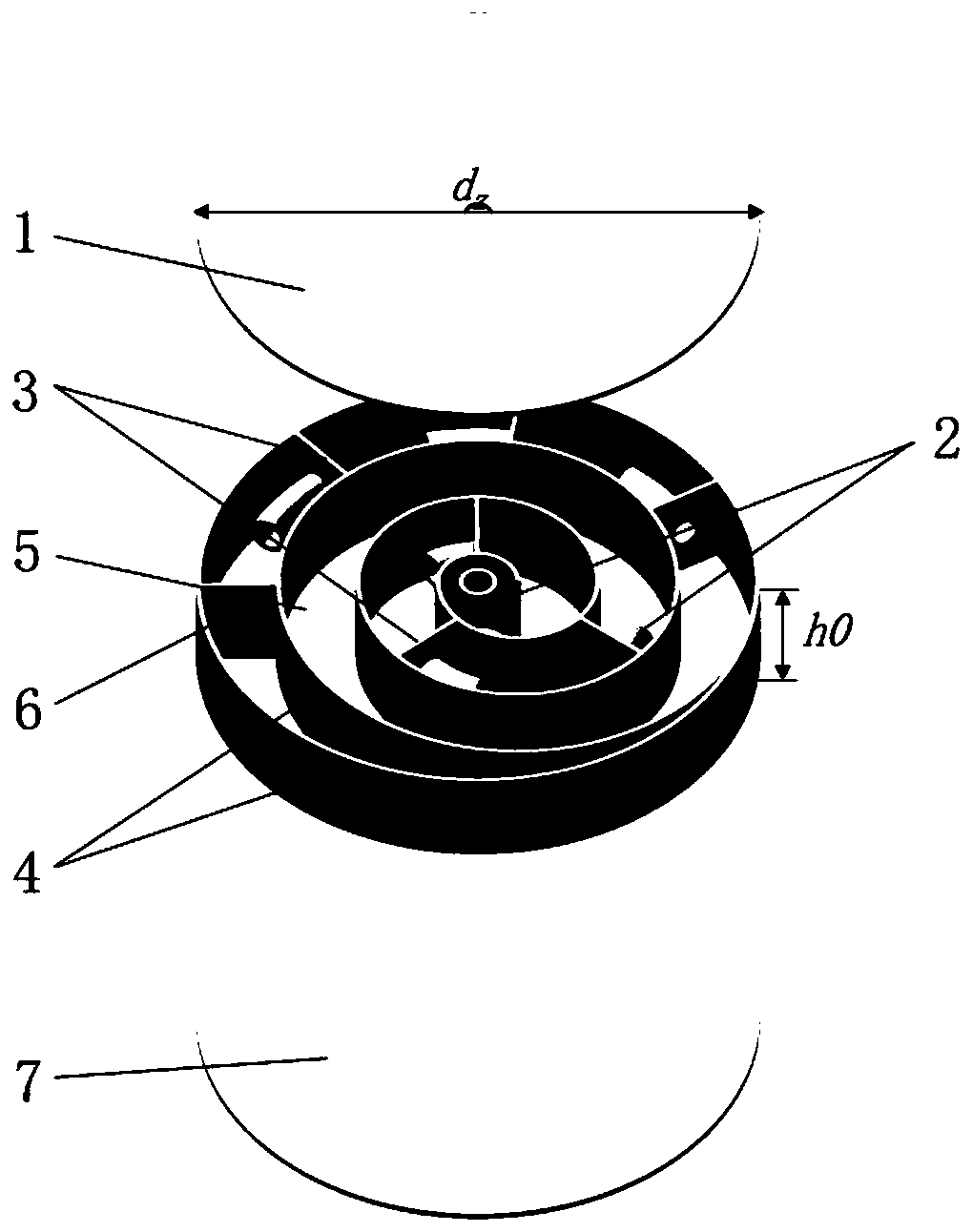

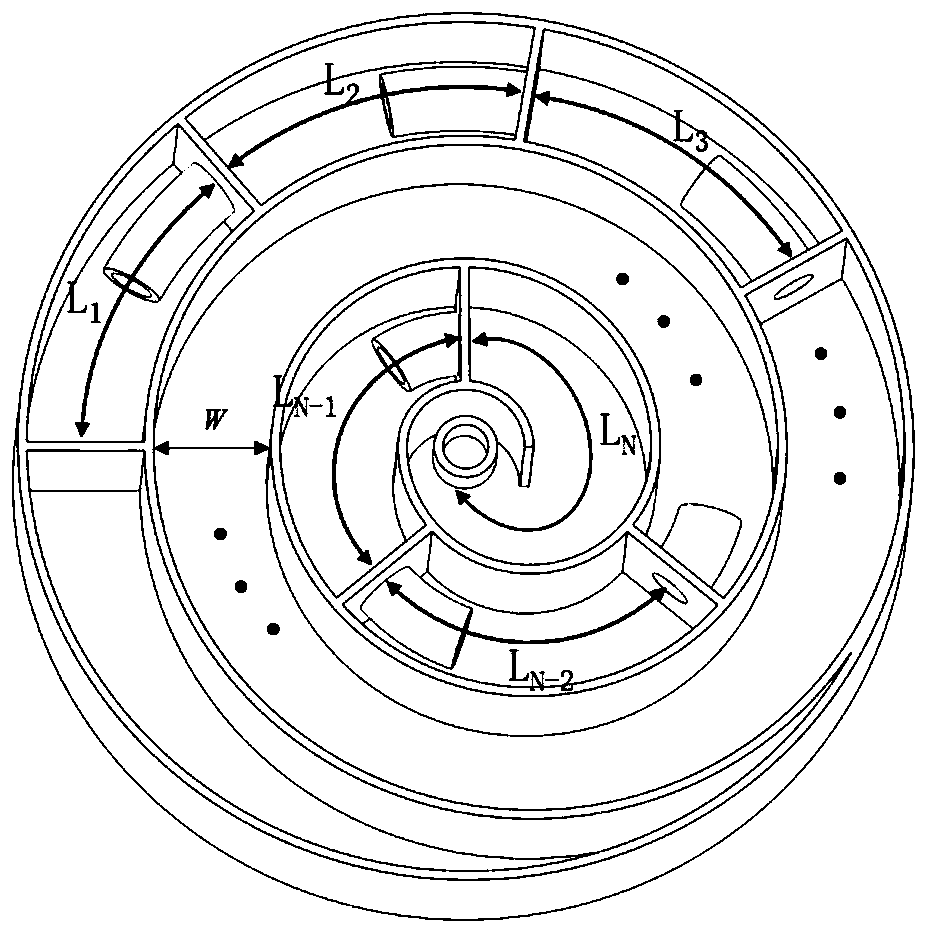

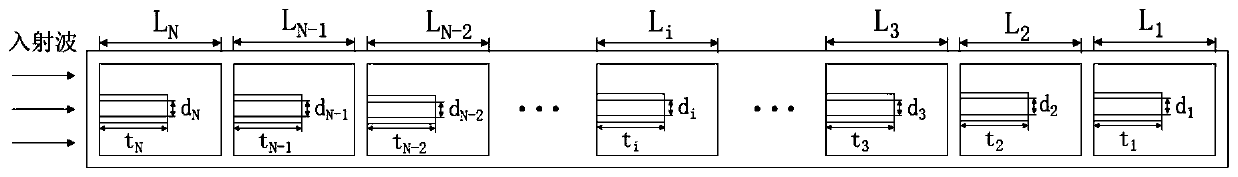

[0042] Embodiment 1: This embodiment provides a circular ultra-thin double-absorption peak sound absorber, such as Figure 4 shown. The main body of the sound absorber is composed of a circular perforated cover plate 1, a cylindrical spiral partition plate 4 and a circular bottom plate 7 closely connected to form a spiral sound-absorbing structure, which encloses a coplanar spiral sound-absorbing cavity 5 in the middle, as The body of the sound absorber. The helical baffle 4 is inserted into the tail of the helical structure to block the irregular rectangular channel and avoid additional acoustic impedance. The perforated baffle 3 is inserted into the helical structure, and the distance L1 from the axis of the helical baffle 4 can be adjusted freely. On the circular perforated cover plate 1 and the perforated baffle plate 3, an embedded annular hole 2 of different size (with a diameter of d i , with length t i , i=1, 2 represent the ordinal number of the embedded circular ...

Embodiment 2

[0054] Embodiment 2: in embodiment 1, all are the samples of double absorption peaks, in order to prove that the sound absorber can produce more absorption peaks, the present embodiment is according to figure 1 The multi-absorption peak structure shown is a sound absorber with three absorption peaks and four absorption peaks. The specific parameters are shown in Table 2:

[0055]

[0056] Figure 7 and Figure 8 The absorption coefficients of the three-absorption peak sound absorber sample B and the four-absorption peak sample C are shown respectively. The absorption peaks of sample B are 146Hz, 442Hz and 653Hz respectively, and the sound absorption coefficients are all above 0.98. The absorption peaks of sample C are 146Hz, 417Hz, 671Hz and 921Hz respectively, and the absorption coefficients are all above 0.97. It can be seen from the figure that the degree of agreement between theory and simulation is high, and the error is not more than 2%. Moreover, the shapes of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com