Method for developing shellfish feed by utilizing waste porphyra yezoensis

A technology of seaweed and shellfish, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of waste, environmental pollution, natural decay, etc., and achieve the effect of increasing the content, protecting the environment, and increasing the pH value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Lay a single layer of Porphyra zebra and dry it naturally or dry it in a constant temperature drying oven at 40°C. Lay flat to keep the Porphyra zebra evenly heated to prevent it from being completely dried, and dry it at a low temperature to avoid streaks The composition of laver changes;

[0028] Then put the dried Porphyra zebra into an ultrafine pulverizer to grind, and the particle size of the dry Porphyra zebra powder after grinding reaches 300 mesh or more, and the filter-feeding property is within 50 microns. Considering that the dry powder will reabsorb and expand after feeding, the volume will increase to ensure that the bait is fed. In the future, the particle size can still be filtered by green clams;

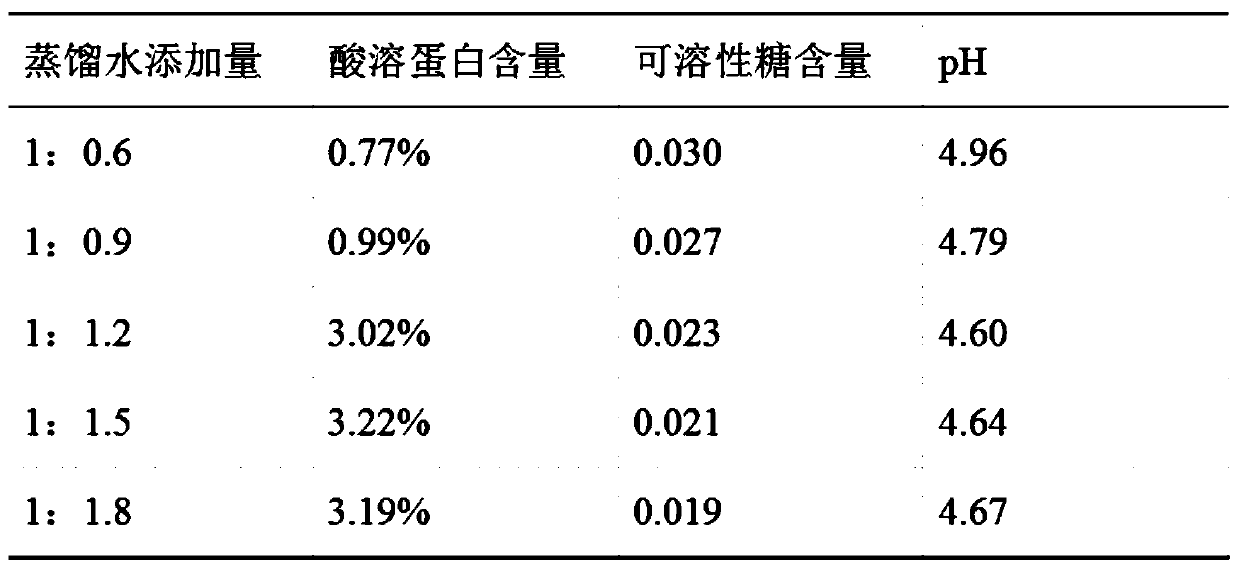

[0029] Finally, add different amounts of distilled water to the dried Porphyra zebra dry powder after the above treatment. The specific gravity of the added amount of distilled water is: 1:0.6, 1:0.9, 1:1.2, 1:1.5, 1:1.8, and then add the same amount of gluco...

Embodiment 2

[0032] Lay a single layer of Porphyra zebra and dry it naturally or dry it in a constant temperature drying oven at 40°C. Lay flat to keep the Porphyra zebra evenly heated to prevent it from being completely dried, and dry it at a low temperature to avoid streaks The composition of laver changes;

[0033] Then put the dried Porphyra zebra into an ultrafine pulverizer to grind, and the particle size of the dry Porphyra zebra powder after grinding reaches 300 mesh or more, and the filter-feeding property is within 50 microns. Considering that the dry powder will reabsorb and expand after feeding, the volume will increase to ensure that the bait is fed. In the future, the particle size can still be filtered by green clams;

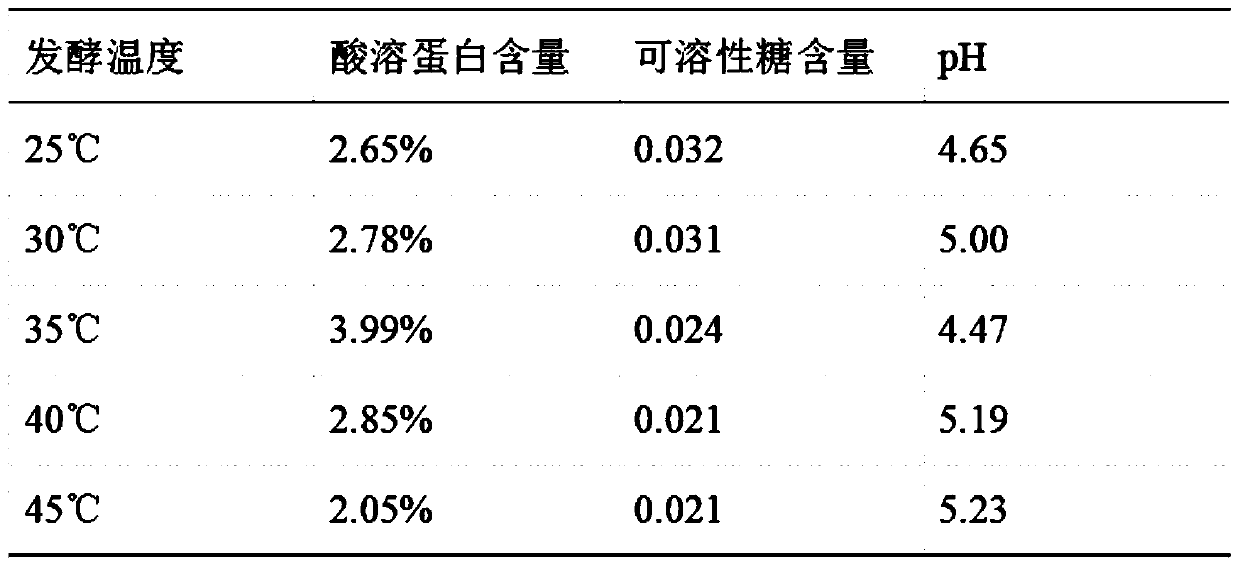

[0034] Finally, add the same amount of distilled water to the dry Porphyra zebra dry powder after the above treatment, then add the same amount of glucose and inoculate the same amount of bacterial strain JSOU-1, mix well, seal and ferment, and put it into th...

Embodiment 3

[0037] Lay a single layer of Porphyra zebra and dry it naturally or dry it in a constant temperature drying oven at 40°C. Lay flat to keep the Porphyra zebra evenly heated to prevent it from being completely dried, and dry it at a low temperature to avoid streaks The composition of laver changes;

[0038] Then put the dried Porphyra zebra into an ultrafine pulverizer to grind, and the particle size of the dry Porphyra zebra powder after grinding reaches 300 mesh or more, and the filter-feeding property is within 50 microns. Considering that the dry powder will reabsorb and expand after feeding, the volume will increase to ensure that the bait is fed. In the future, the particle size can still be filtered by green clams;

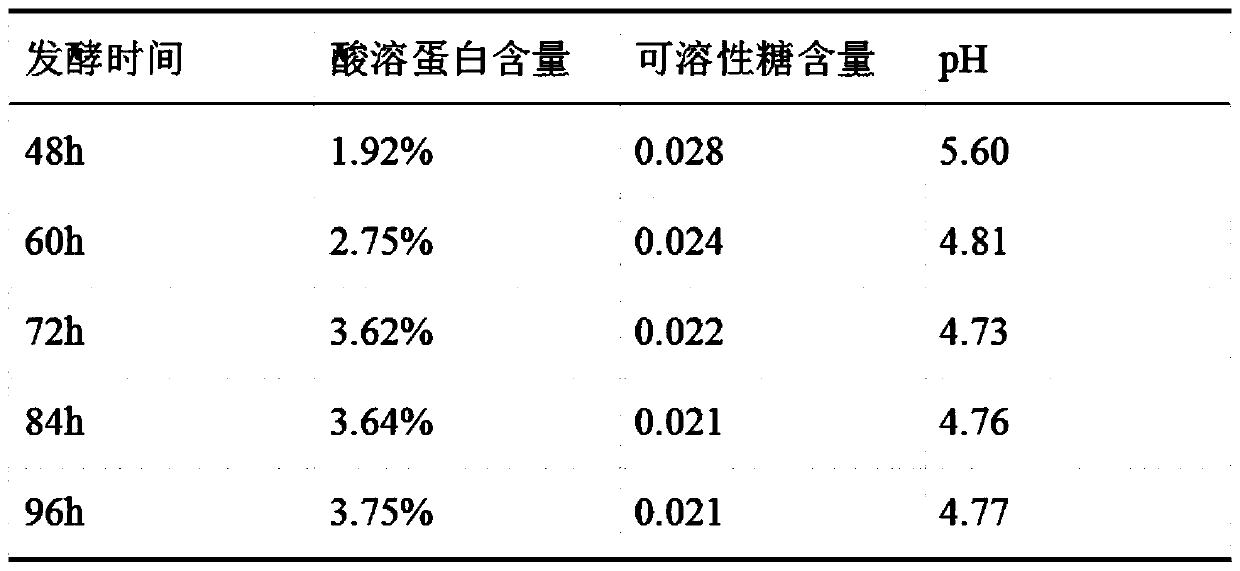

[0039] Finally, add the same amount of distilled water to the dry Porphyra zebra dry powder after the above treatment, add the same amount of glucose and inoculate the same amount of strain JSOU-1, mix well, seal and ferment, put it in a 35°C thermostat for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com