Catalyst for hydrogenation of CO2 to prepare methane, and preparation method of catalyst

A catalyst, a technology for producing methane, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst, etc., can solve the problems of cumbersome synthesis process and unenvironmental protection, and achieves simple process and utilization rate. High, prevent sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0027] a CO 2 The preparation method of hydrogenation methane catalyst comprises the steps:

[0028] 1) Weigh 10.0 g of Arborvitae leaves, mix them with 150 mL of deionized water, boil in an oil bath at 120°C for 5 minutes, take them out, cool to room temperature, and filter with suction to obtain the extract of Arborvitae;

[0029] 2) Take three parts of the 25 mL step 1) of the Thuja arborvitae extract, place them in 50 mL beakers, heat and stir in an oil bath at 90 ° C, and then add palladium nitrate, chloroplatinic acid, and nitric acid to different beakers Silver (control loading is 3wt%), then add 0.4000g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 0.2688g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) (the amount of lanthanum nitrate and cobalt nitrate is 1:1), continue to heat and stir until the solution is evaporated to dryness (about 3h), then transfer the sample to the crucible, in the muffle furnace at 2 ℃ / min Calcination for 1 hour after the heating rate rises from ro...

Embodiment 4~7

[0039] The difference between Examples 4-7 and Example 1 is that the loaded amount of noble metal Pd is different, respectively 0.5% Pd@LaCoO 3 , 1.0% Pd@LaCoO 3 , 5.0% Pd@LaCoO 3 and 8.0% Pt@LaCoO 3 sample.

Embodiment 8~11

[0041] The difference between Examples 8-11 and Example 1 is that 3% Pd@LaCoO is prepared under calcination conditions of 600, 700, 800 and 900°C respectively 3 .

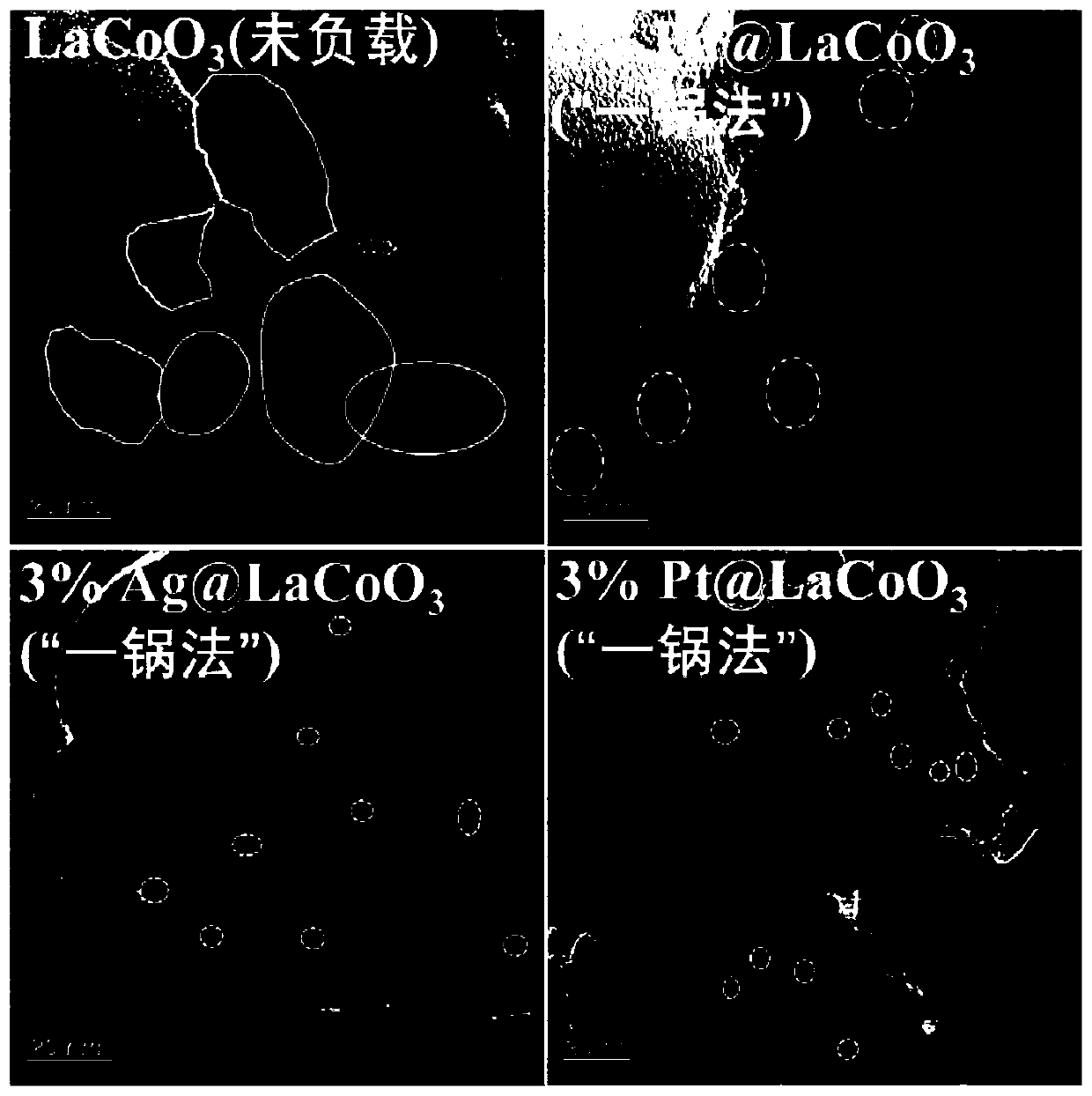

[0042] One, embodiment 1~3, comparative example 1 and 2 morphology comparison

[0043] Such as figure 1 , the upper left is the LaCoO prepared in Comparative Example 1 3 (Unloaded) samples, shown in the figure as nanoparticles with a diameter of 20-50nm, which are relatively uniform inside, and no fine nanoparticles are observed; while the 3%Pd@LaCoO prepared in Examples 1-3 3 (upper right), 3% Ag@LaCoO 3 (bottom left) and 3%Pt@LaCoO 3 (Bottom right) samples, LaCoO can be observed 3 Nanoparticles (20-50nm) contain nanoparticles with a diameter of 3-8nm inside, which shows that the sample prepared by the "one-pot method" of plant extracts has a special core-shell structure, and the noble metal (as the core) is covered by LaCoO 3 Wrapped inside (for the shell).

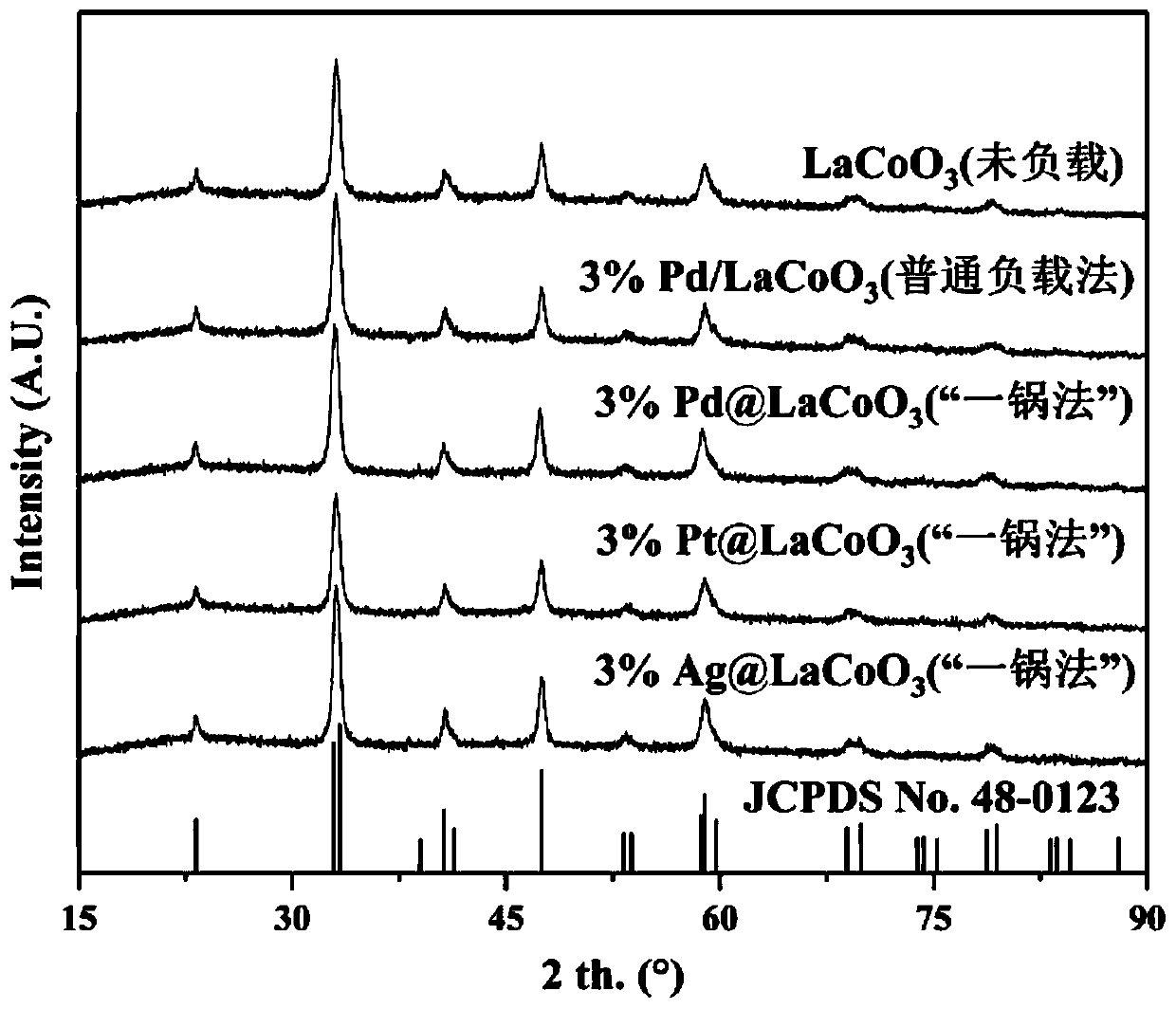

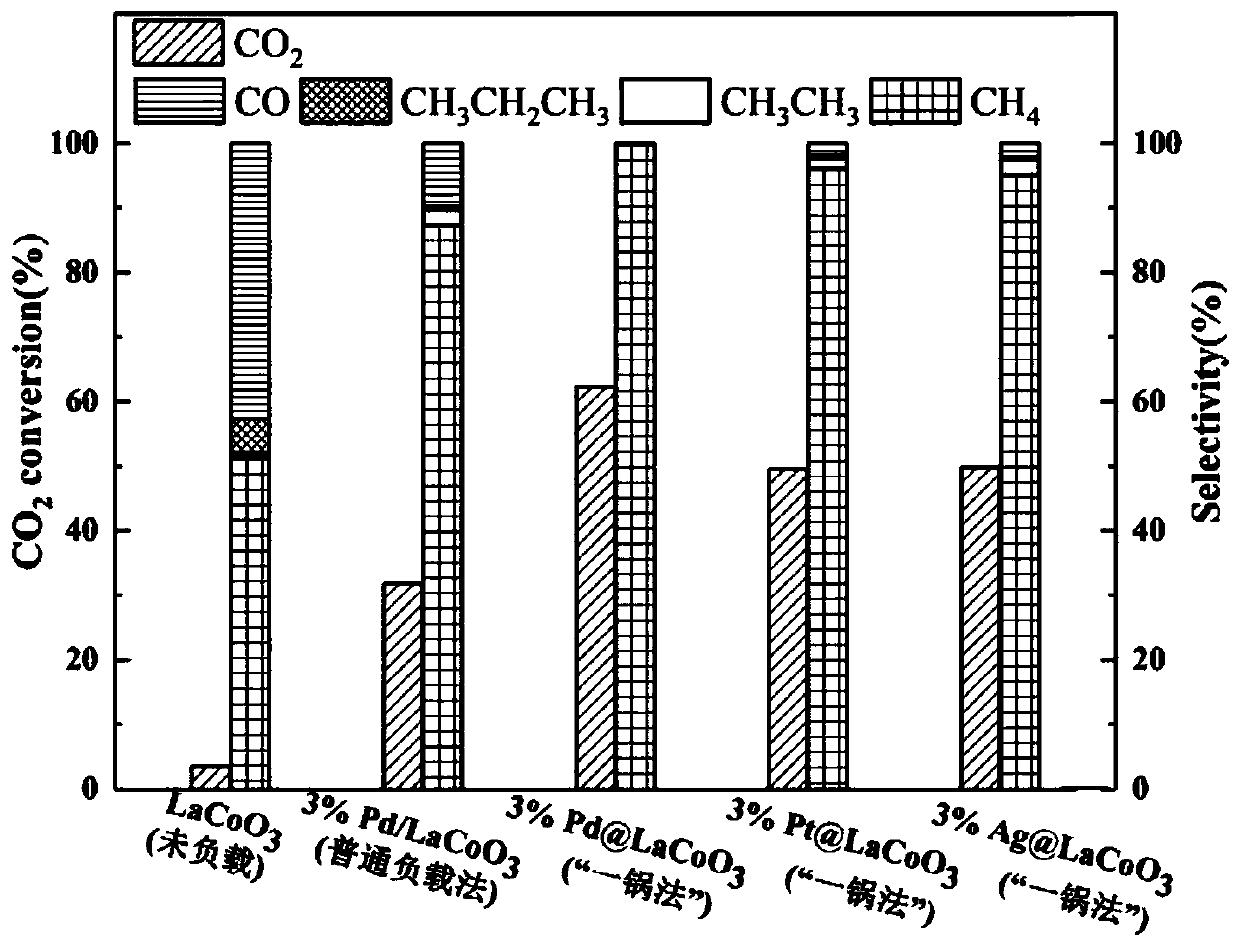

[0044] Such as figure 2 , the peaks of each s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com