Ecological block prepared by riverway silt, and method and device for preparing ecological block

A technology for river silt and silt, applied in chemical instruments and methods, sludge treatment, manufacturing tools, etc., can solve the problems of low acceptance, limited scope of application, low addition of solid waste, etc., and achieve good environmental protection, The effect of excellent compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

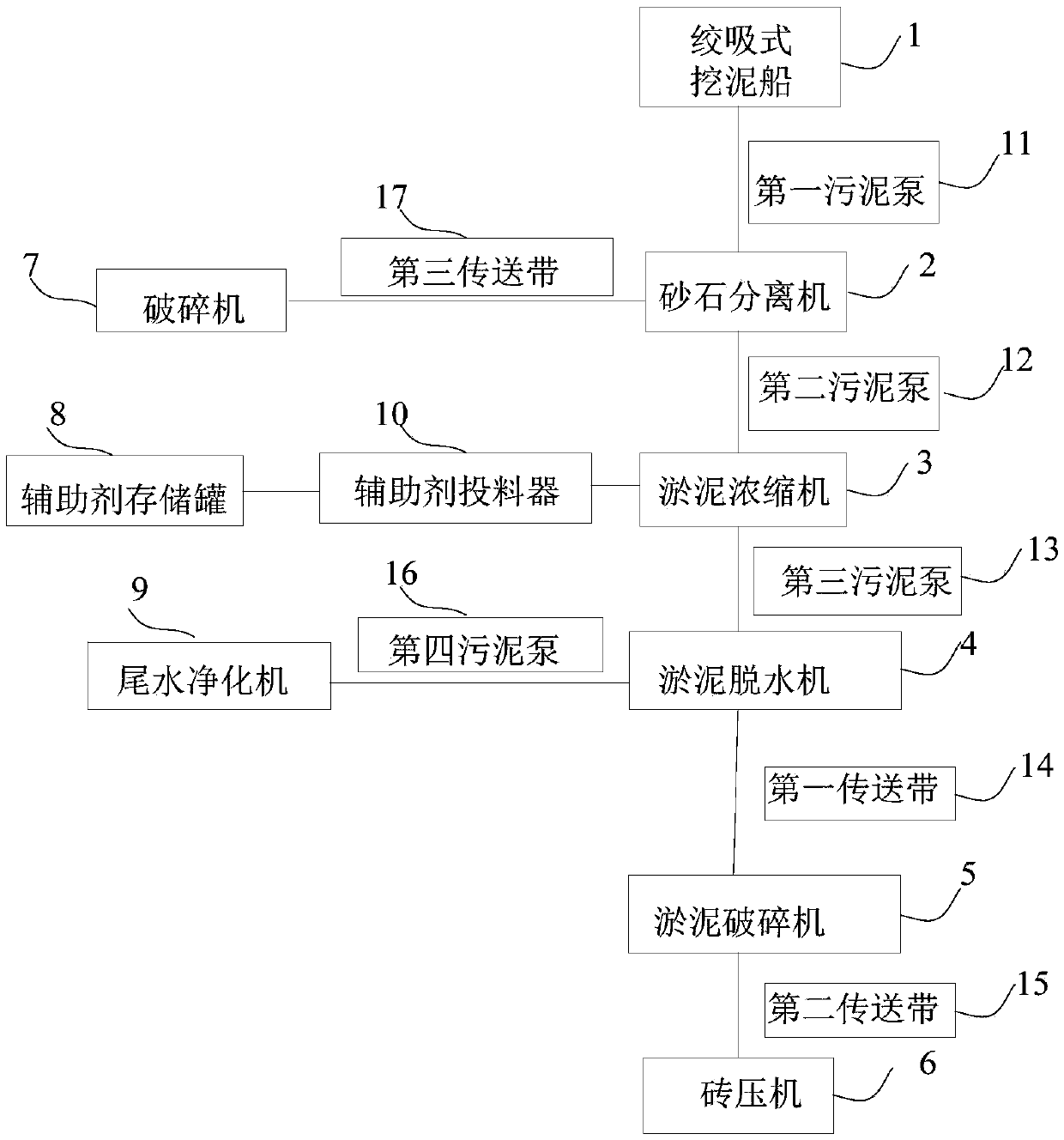

Image

Examples

Embodiment 1

[0047] The river silt of a river in Shenzhen City, Guangdong Province is dredged by a cutter suction dredger to obtain the dredged river silt, and the dredged river silt is pumped to the sand and gravel separator through the first sludge pump. The stone separator separates the material with a particle size of more than 2mm from the dredged river silt, among which the particle size of more than 3mm is regarded as garbage and removed, and the particle size of 2-3mm is sand, which can be used as fine bone After removing the garbage and separating the sand and gravel, the pretreated river sludge is obtained; the pretreated river sludge is pumped to the sludge thickener through the second sludge pump, and then sent to the pretreated sludge thickener through the auxiliary agent feeder. Put into the treated river silt auxiliary agent to carry out passivation conditioning and concentration, obtain passivated river silt, relative to the weight of dry mud per ton of river silt, put in 50...

Embodiment 2

[0049] The river silt of a river in Shenzhen City, Guangdong Province is dredged by a cutter suction dredger to obtain the dredged river silt, and the dredged river silt is pumped to the sand and gravel separator through the first sludge pump, and the sand and gravel The separator separates the material with a particle size of more than 2mm in the dredged river silt, among which the particle size of more than 3mm is regarded as garbage and removed, and the particle size of 2-3mm is sand, which can be used as fine aggregate Use, remove the garbage and separate the sand and gravel to get the pretreated river sludge; the pretreated river sludge is pumped to the sludge thickener by the second sludge pump, and then sent to the sludge thickener for pretreatment through the auxiliary agent feeder Add auxiliary agent in the final river silt for passivation conditioning and concentration to obtain passivated river silt, relative to the weight of dry mud per ton of river silt, input calc...

Embodiment 3

[0051]The river silt of a river in Shenzhen City, Guangdong Province is dredged by a cutter suction dredger to obtain the dredged river silt, and the dredged river silt is pumped to the sand and gravel separator through the first sludge pump, and the sand and gravel The separator separates the material with a particle size of more than 2mm in the dredged river silt, among which the particle size of more than 3mm is regarded as garbage and removed, and the particle size of 2-3mm is sand, which can be used as fine aggregate Use, remove the garbage and separate the sand and gravel to get the pretreated river sludge; the pretreated river sludge is pumped to the sludge thickener by the second sludge pump, and then sent to the sludge thickener for pretreatment through the auxiliary agent feeder Add auxiliary agent in the final river silt for passivation conditioning and concentration to obtain passivated river silt, relative to the weight of dry mud per ton of river silt, input calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com