Preparation method of aluminum-doped graphene material

A graphene and aluminum doping technology, applied in the field of materials, can solve problems such as changing physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

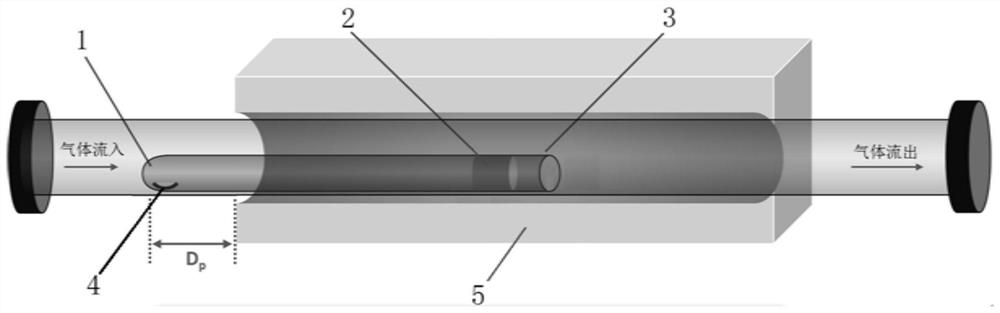

[0036] The present embodiment provides a kind of preparation method of aluminum-doped graphene material, and the steps are as follows:

[0037] 1. Vacuuming: The CVD system vacuum system is used to pump the vacuum of the furnace body below 28 Pascals to remove the influence of other gases in the furnace body.

[0038] 2. Purge: use argon (200 sccm) to purge the furnace body to further improve the cleanliness of the furnace body.

[0039] 3. Heating: Heating the furnace body to raise the temperature from room temperature to 1025 degrees Celsius within 45 minutes, and during the heating process, feed 5v% hydrogen and 95v% argon (16sccm).

[0040] 4. Annealing: Place the copper foil T (4.5cm x 1cm) inside the quartz tube built in the furnace body. The diameter of the quartz tube is 15mm. Heat it at 1025 degrees Celsius for 30 minutes. During the whole process, it is in 5v% hydrogen and 95v% argon (16sccm) atmosphere. The quartz tube has a cylindrical shape including a curved cl...

Embodiment 2

[0046] The present embodiment provides a kind of preparation method of aluminum-doped graphene material, and the steps are as follows:

[0047] 1. Vacuuming: The CVD system vacuum system is used to pump the vacuum of the furnace body below 28 Pascals to remove the influence of other gases in the furnace body.

[0048] 2. Purge: use argon (200 sccm) to purge the furnace body to further improve the cleanliness of the furnace body.

[0049] 3. Heating: The furnace body is heated to raise the temperature. Within 45 minutes, the temperature rises from room temperature to 1025 degrees Celsius, and during the heating process, 5v% hydrogen and 95v% argon (16sccm) are introduced.

[0050] 4. Annealing: Place the copper foil T (4.5cm x 1cm) in the quartz tube built in the furnace body. The diameter of the quartz tube is 15mm, and heat at 1025 degrees Celsius for 30 minutes. The quartz tube has a cylindrical shape including a curved closed end and an open end. The closed end of the qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com