Universal synthesis method for nanocrystals

A synthesis method and nanocrystal technology, applied in the fields of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of uneven particle size, application limitations of nanomaterials, and inability to universally prepare a variety of nanocrystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1Z

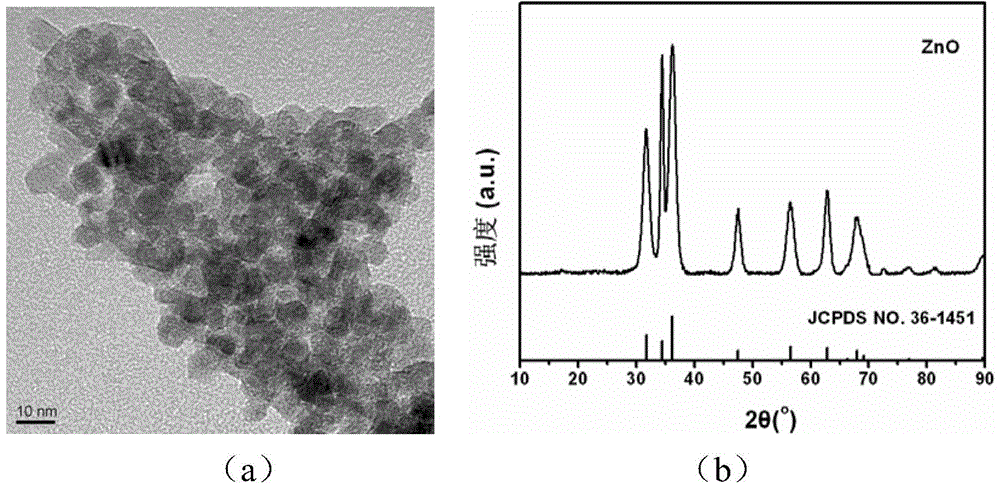

[0039] The synthesis of embodiment 1ZnO nanocrystal

[0040] Dissolve 0.05mol of zinc acetate in 10mL of water and 30mL of pyridine in a mixed solvent; at the same time, dissolve 0.05mol of potassium hydroxide in 30mL of water; then, drop the potassium hydroxide solution into the zinc acetate solution for 20 minutes; finally, the reaction The temperature of the solution was raised to 80°C, and the reaction was carried out for 2 hours. The zinc oxide nanoparticles were precipitated with acetone and centrifuged to obtain a white solid. Add 30mL of water, sonicate for 10min; then add 30mL of acetone, and centrifuge to obtain pure zinc oxide nanoparticles. figure 1 shown.

Embodiment 2

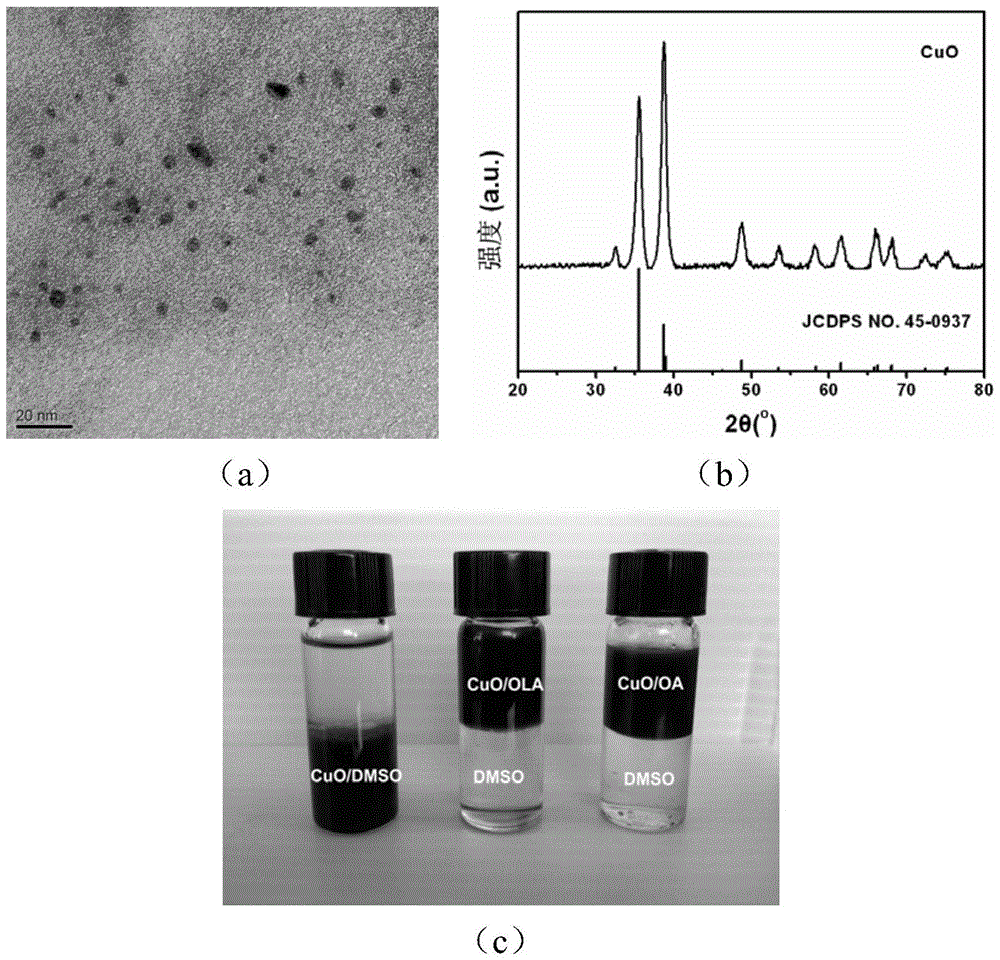

[0041] The synthesis of embodiment 2CuO nanocrystals

[0042] Dissolve 0.05mol of copper acetate in 10mL of water and 30mL of pyridine mixed solvent, then heat up to 80°C; at the same time, dissolve 0.05mol of potassium hydroxide in 30mL of water, drop into the copper acetate solution, finish dripping in 20min, and react for 2h. The copper sulfide nanoparticles were precipitated with acetone and centrifuged to obtain a dark brown solid. Add 30mL of water, sonicate for 10min; then add 30mL of acetone, and centrifuge to obtain pure copper oxide nanoparticles. The transmission electron microscope and XRD images are as follows figure 2 shown.

Embodiment 3

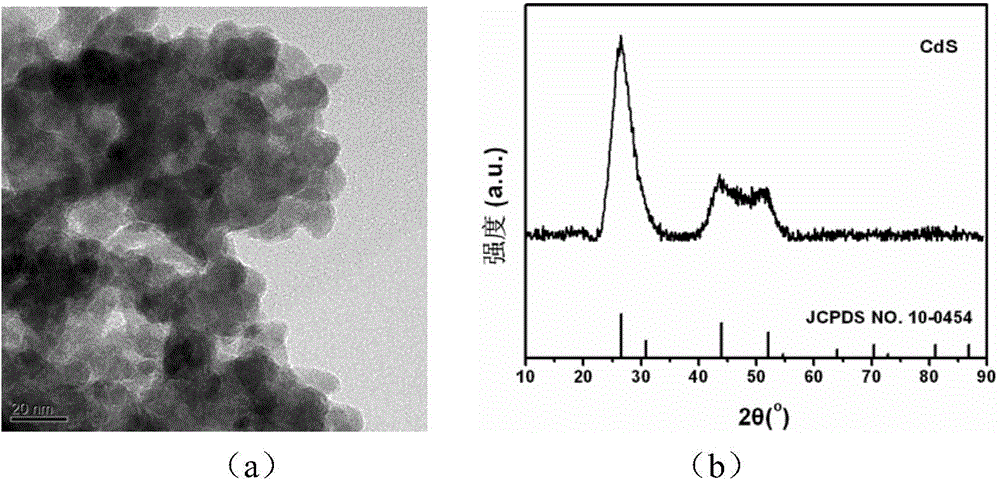

[0043] The synthesis of embodiment 3CdS nanocrystals

[0044] Dissolve 0.05mol cadmium acetate in a mixed solvent of 10mL water and 30mL pyridine, then raise the temperature to 80°C; at the same time, dissolve 0.05mol sodium sulfide in 30mL water, drop into the cadmium acetate solution, finish dripping in 20min, and react for 2h. The cadmium sulfide nanoparticles were settled down with acetone and centrifuged to obtain an orange-yellow solid. Add 30mL water, sonicate for 10min; then add 30mL acetone, and centrifuge to obtain pure cadmium sulfide nanoparticles. The TEM and XRD images are as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com