Multi-path electroplating liquid iron removal device and multi-path electroplating liquid iron removal method

An electroplating solution, multi-channel technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

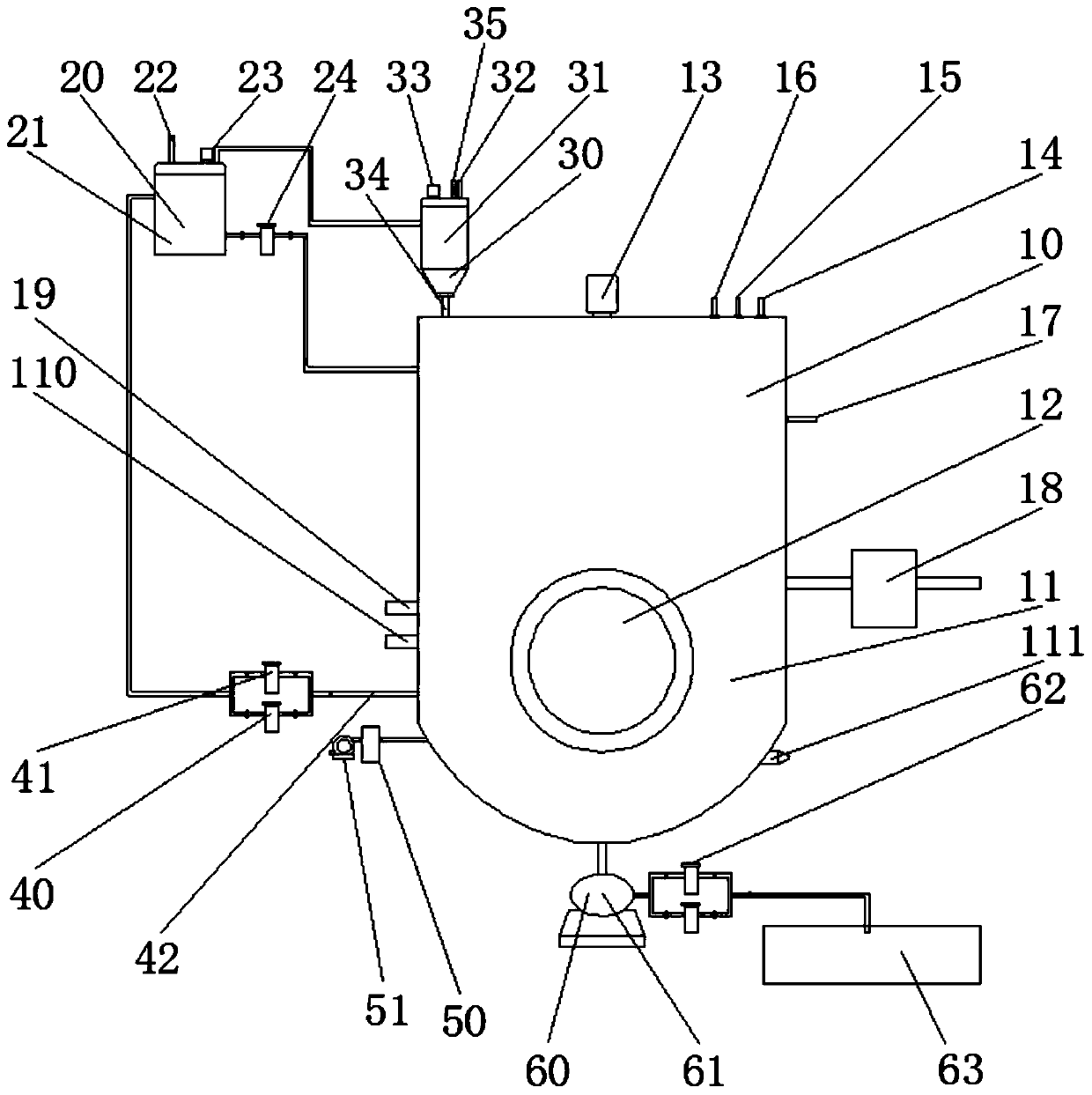

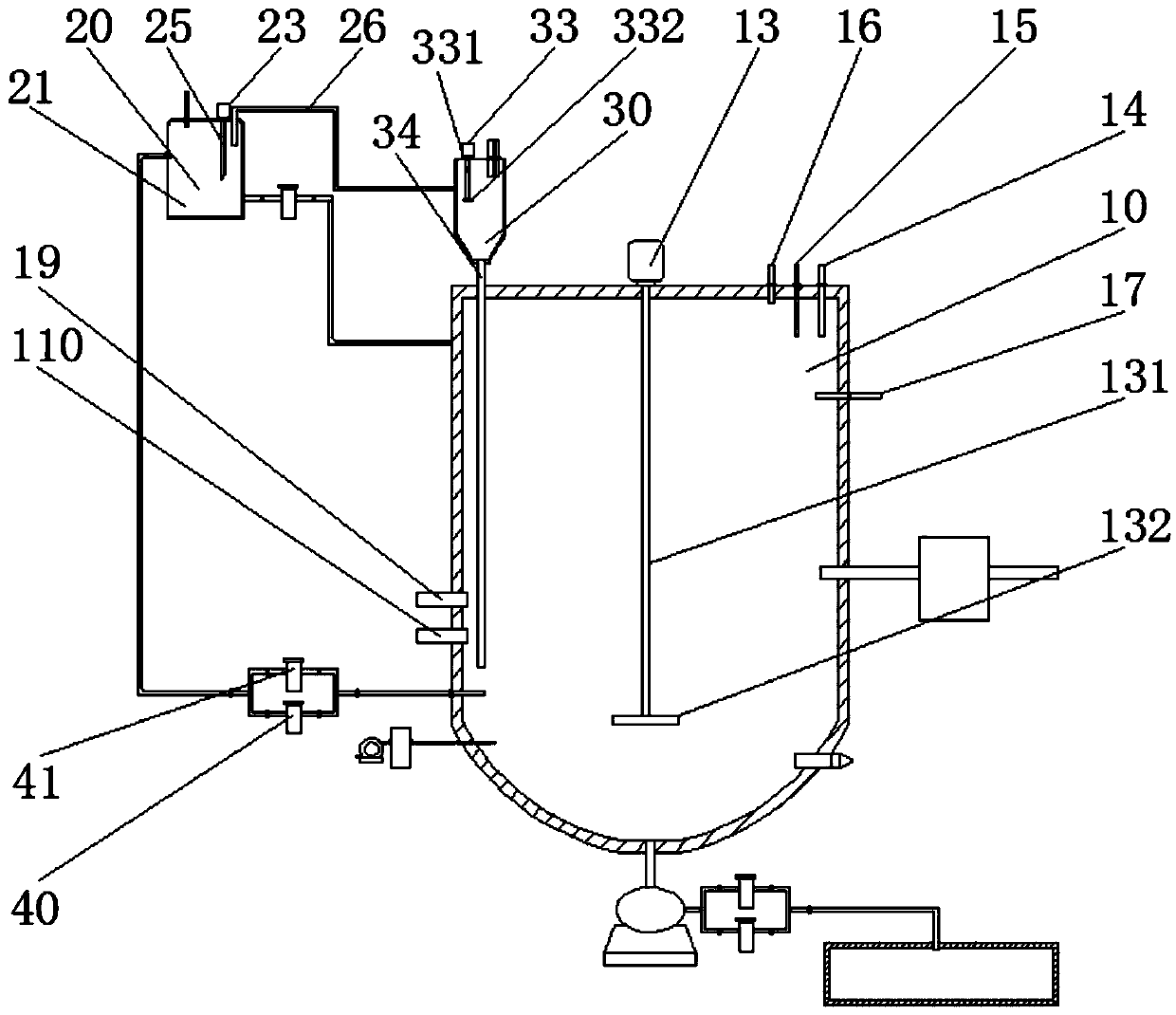

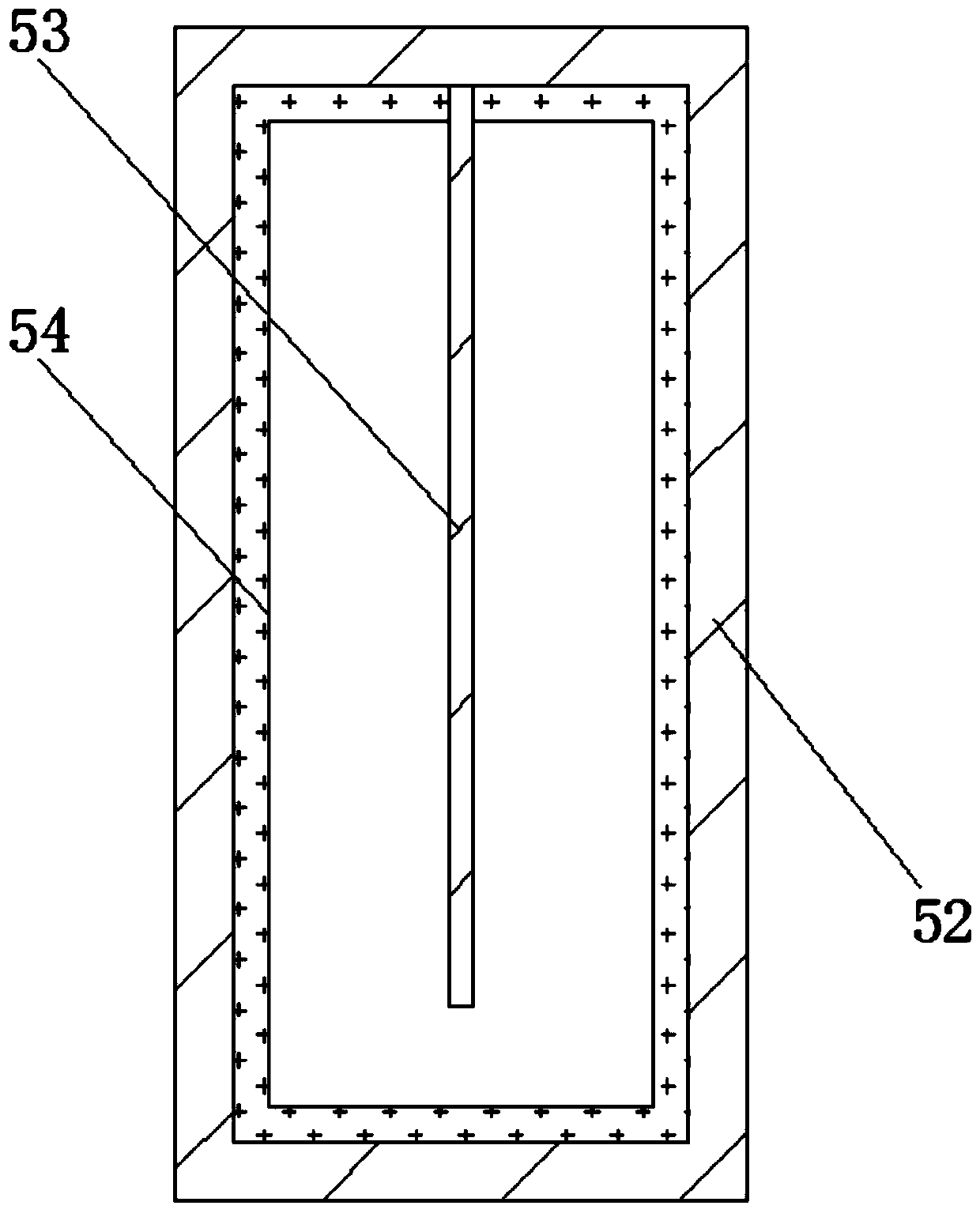

[0042] The present invention provides such Figure 1-3 A multi-channel electroplating solution iron removal device shown includes:

[0043] The electroplating solution treatment assembly 10, the electroplating solution treatment assembly 10 includes a treatment tank 11, a manhole 12, a first motor 13, a first rotating shaft 131, a first stirring blade 132, a plating solution inlet pipe 14, an alkali solution inlet pipe 15, The first exhaust pipeline 16, the oxidant liquid filling pipe 17, the gas compressor 18, the pH meter 19, the thermometer 110 and the liquid level gauge 111;

[0044] Zinc dissolving assembly 20, described dissolving zinc assembly 20 is installed on one side of described electroplating solution treatment assembly 10, and described zinc dissolving assembly 20 comprises zinc dissolving tank 21, second exhaust pipe 22, zinc dissolving bucket 23, first A filter 24, a first liquid inlet pipe 25 and a second liquid inlet pipe 26, the outlet end of the first filt...

experiment example 1

[0082] The present invention also provides a comparison of the experimental results of Example 1, Comparative Example 1 and Comparative Example 2, and the comparison results are shown in Table 1:

[0083] Table 1

[0084]

[0085] It is found through comparison that the single electroplating solution treatment cycle of embodiment one is 4-8h / time, and all electroplating solutions in the electroplating circulation tank can be processed in 3-5 days, which is high-speed processing;

[0086] Comparative example one single electroplating zinc solution treatment cycle is 12-24h / time, 7-10 days can make all the electroplating solutions in the electroplating circulation tank be processed, which is medium speed treatment;

[0087] Comparative Example 2 The single electroplating solution treatment cycle is 2.5-3d / time, and all the electroplating solutions in the electroplating circulation tank can be processed in 25-30 days and months, which is a low-speed treatment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap