Synthesis formula and construction method of environment-friendly suspension type assembled floor

A floor and environmental protection technology, applied in the direction of elastic floor, building, building structure, etc., can solve the problems of short service life, reduced practicability, and reduced floor aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

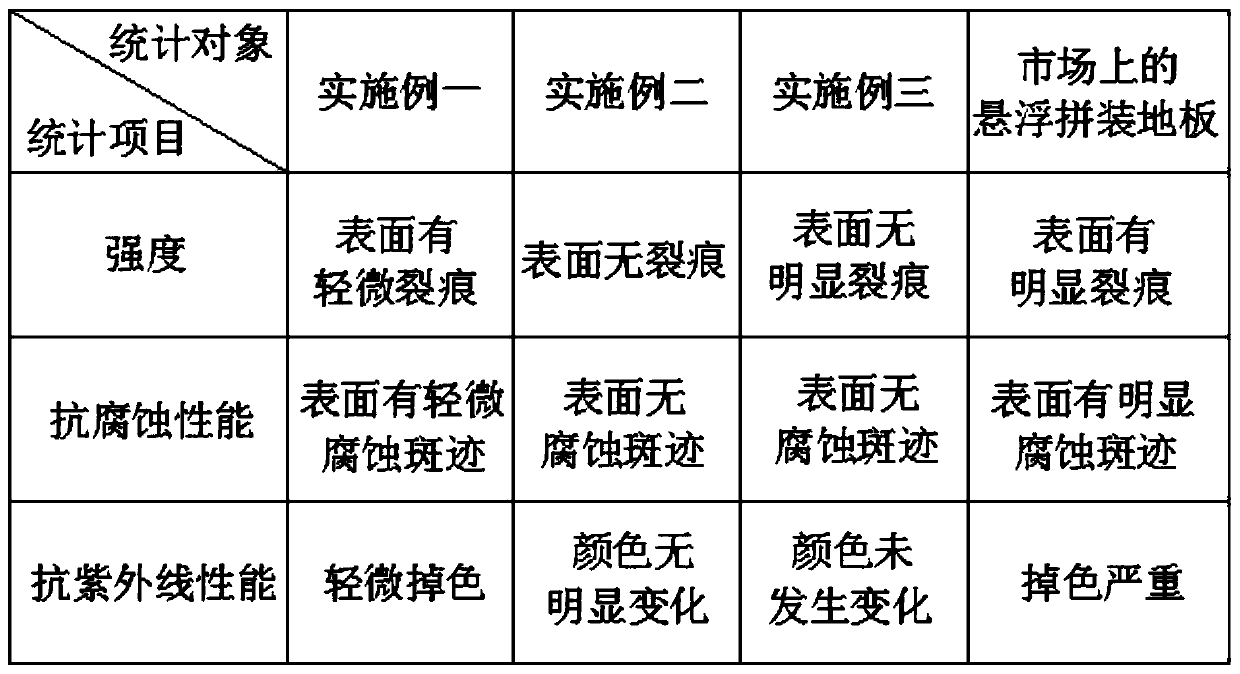

Embodiment 1

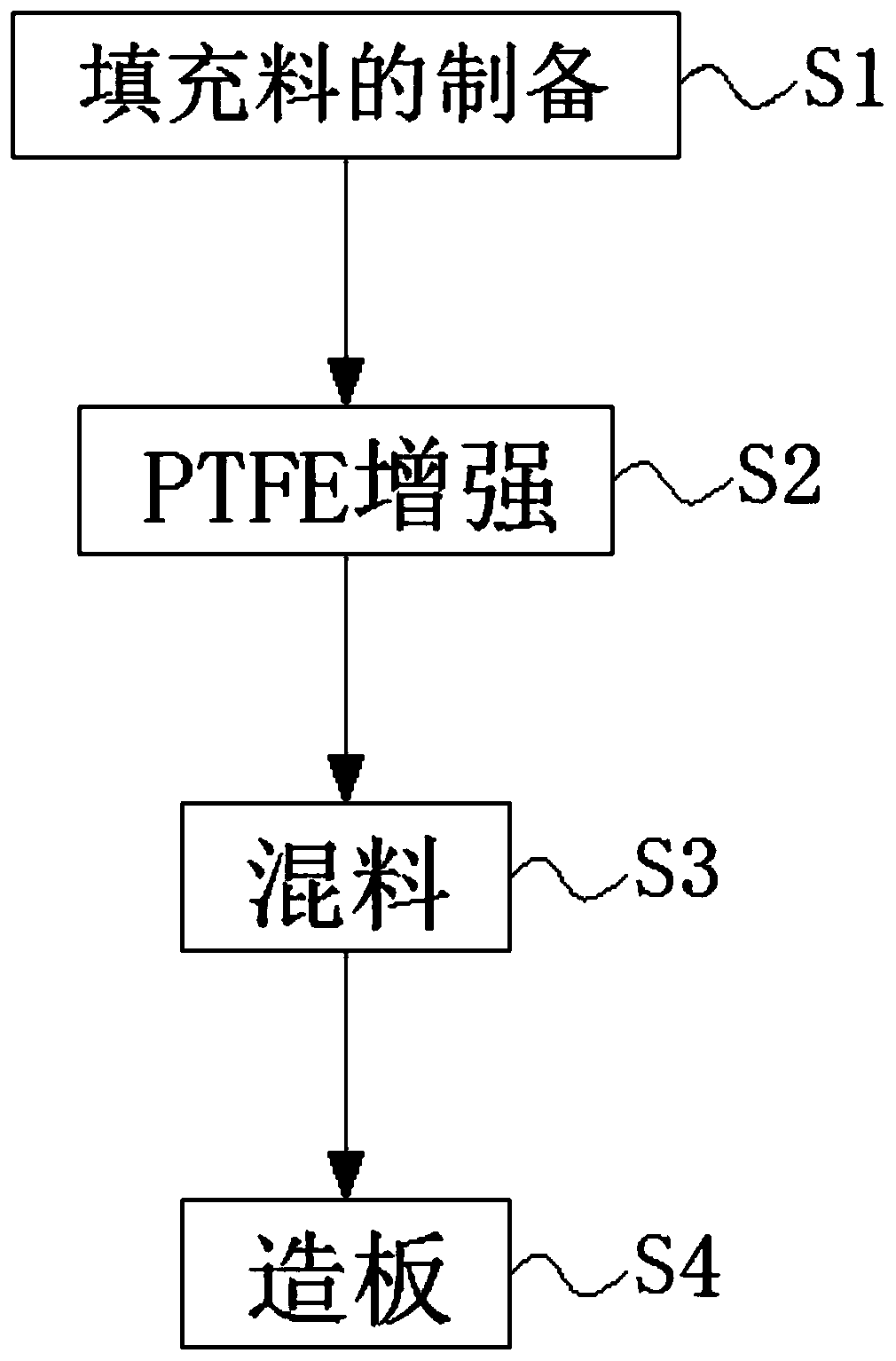

[0028] S1. Preparation of filling material: put an appropriate amount of ABS particles into the reactor, and add PC particles into the reactor so that the mass ratio of ABS to PC is 4:1. Stir at a rotating speed of 45 to prepare the filler;

[0029] S2, PTFE reinforcement: Put 10 parts of PTFE into the reaction kettle, stir at 330°C to melt, then add 8 glass fibers, stir at 800r / min for 50min, mix well and adjust the temperature to 15°C, then coagulate, wash with water, and dry to produce high-strength PTEF fine particles;

[0030] S3. Mixing: Take 20 parts of the filler prepared in S1 and add it to the high-strength PTEF fine particles prepared in S2, and add 10 parts of TPE and 40 parts of polypropylene to the reaction kettle, at a speed of 800r / min After stirring for 8 hours, then add 20 parts of sepiolite powder and 8 parts of anti-ultraviolet additive, and stir for 20 minutes at a speed of 1200r / min to mix the materials evenly to obtain a raw material mixture.

[0031] ...

Embodiment 2

[0033] S1. Preparation of filling material: put an appropriate amount of ABS particles into the reactor, and add PC particles into the reactor so that the mass ratio of ABS to PC is 4:1. Stir at a rotating speed of 50min to prepare the filler;

[0034] S2, PTFE reinforcement: Put 15 parts of PTFE into the reaction kettle, stir at 335°C to melt it, then add an appropriate amount of glass fiber, stir at a speed of 800r / min for 60min, and adjust the temperature after mixing evenly to 17°C, then coagulate, wash with water, and dry to produce high-strength PTEF fine particles;

[0035]S3. Mixing materials: Take 27 parts of the filler prepared in S1 and add it to the high-strength PTEF fine particles prepared in S2, and add 13 parts of TPE and 50 parts of polypropylene to the reaction kettle, at a speed of 800r / min After stirring for 9 minutes, 35 parts of sepiolite powder and 10 parts of anti-ultraviolet additives were added, and stirred at a speed of 1200 r / min for 23 minutes to ...

Embodiment 3

[0038] S1. Preparation of filling materials: put an appropriate amount of ABS particles into the reactor, and add PC particles into the reactor so that the mass ratio of ABS to PC is 4:1. Stir at a rotating speed of 55min to prepare the filler;

[0039] S2, PTFE reinforcement: put 20 parts of PTFE into the reaction kettle, stir at 340°C to melt it, then add an appropriate amount of glass fiber, stir at 800r / min for 70min, mix well and adjust the temperature to 20°C, then coagulate, wash with water, and dry to produce high-strength PTEF fine particles;

[0040] S3. Mixing: Take 34 parts of the filler prepared in S1 and add it to the high-strength PTEF fine particles prepared in S2, and add 15 parts of TPE and 60 parts of polypropylene to the reaction kettle, at a speed of 800r / min After stirring for 10 minutes, 50 parts of sepiolite powder and 12 parts of anti-ultraviolet additive were added, and stirred at a speed of 1200 r / min for 25 minutes to mix the materials evenly to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com