A kind of cold-rolled enamel steel and its manufacturing method

A manufacturing method and technology of enamelled steel, applied in the field of enamelled steel and its manufacture, can solve the problems of poor enamel adhesion and low yield strength of cold-rolled enamelled steel, and achieve good adhesion performance, good comprehensive performance, good formability and scale resistance explosive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

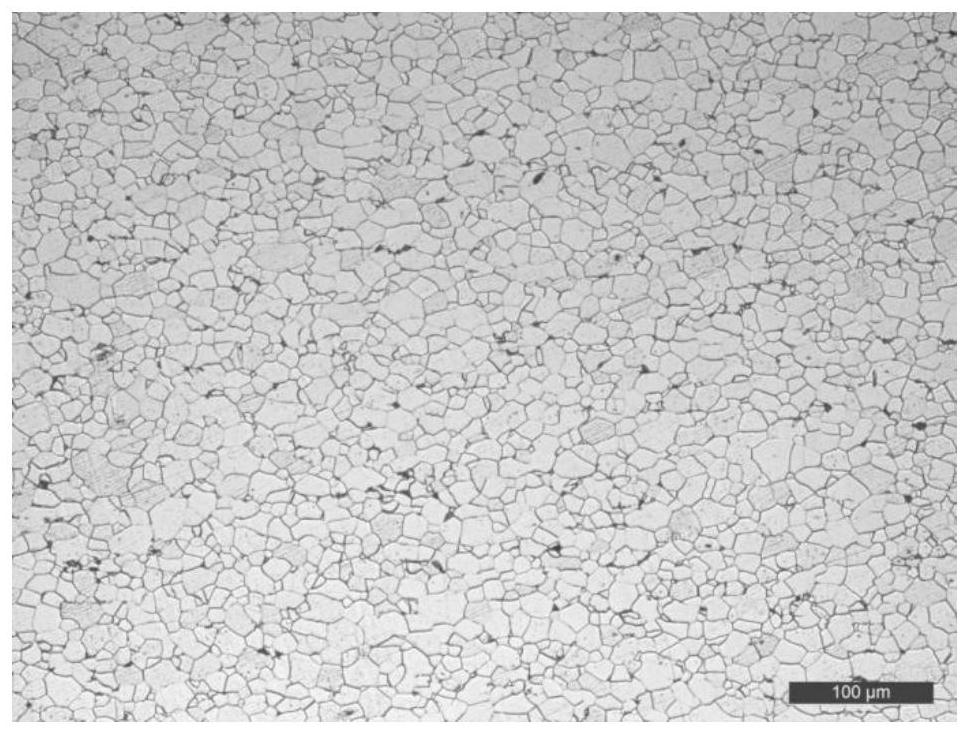

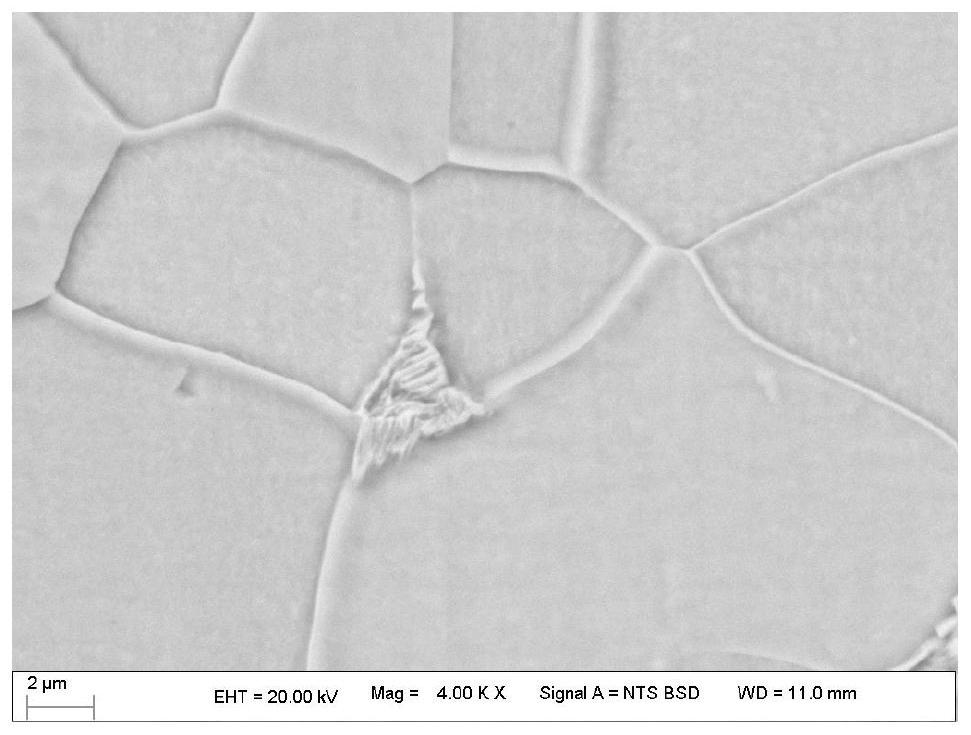

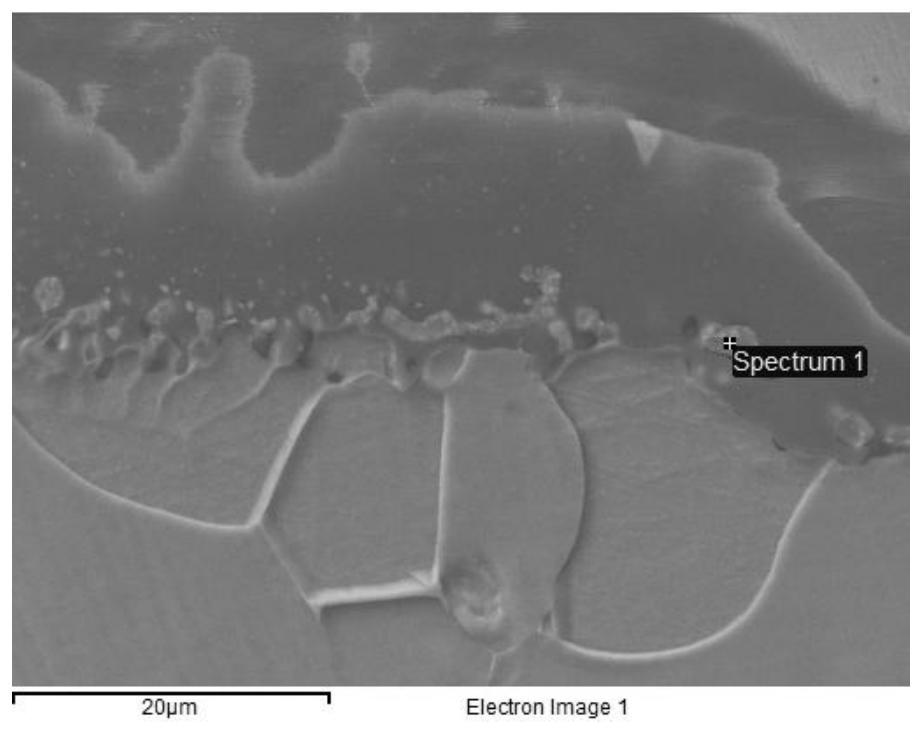

Image

Examples

Embodiment 1-6 and comparative example 1-2

[0065] Table 1-1 and Table 1-2 list the mass percent of each chemical element in the cold-rolled enamelled steel of Example 1-6 and Comparative Example 1-2.

[0066] Table 1-1. (wt%, the balance is Fe and unavoidable impurities other than S)

[0067]

[0068]

[0069] Table 1-2. (wt%, the balance is Fe and unavoidable impurities other than S)

[0070]

[0071] Note: Ti×O×10 4 , Si×(O-2 / 3Ti)×10 4 , 3.43N+1.5S, Ti×N×10 4 , (Ti-3.43N)×S×10 4 Ti, O, Si, N, and S in all represent their respective mass percentages, and the values substituted are the values before the percentage sign.

[0072] The cold-rolled enamelled steels of Examples 1-6 and Comparative Examples 1-2 were produced through the following steps (see Table 2-1 and Table 2-2 for specific process parameters):

[0073] (1) The molten iron is pretreated according to the mass percentage of each chemical element in Table 1-1 and Table 1-2, and the cast slab is obtained through converter smelting, refining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com