High-performance COB display screen of double-layer packaging protection and packaging method

A packaging method and high-performance technology, applied in the identification of devices, instruments, electrical components, etc., can solve problems such as short circuit of LED chips, LED failure, etc., to avoid warping deformation, rapid repair, and improve the process level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

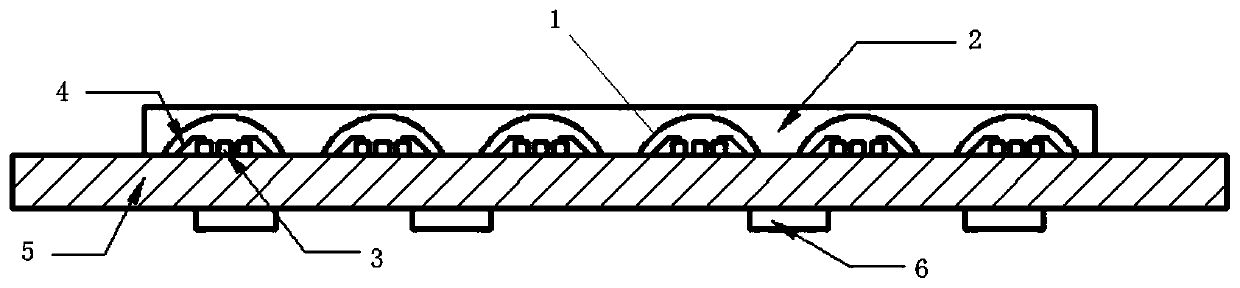

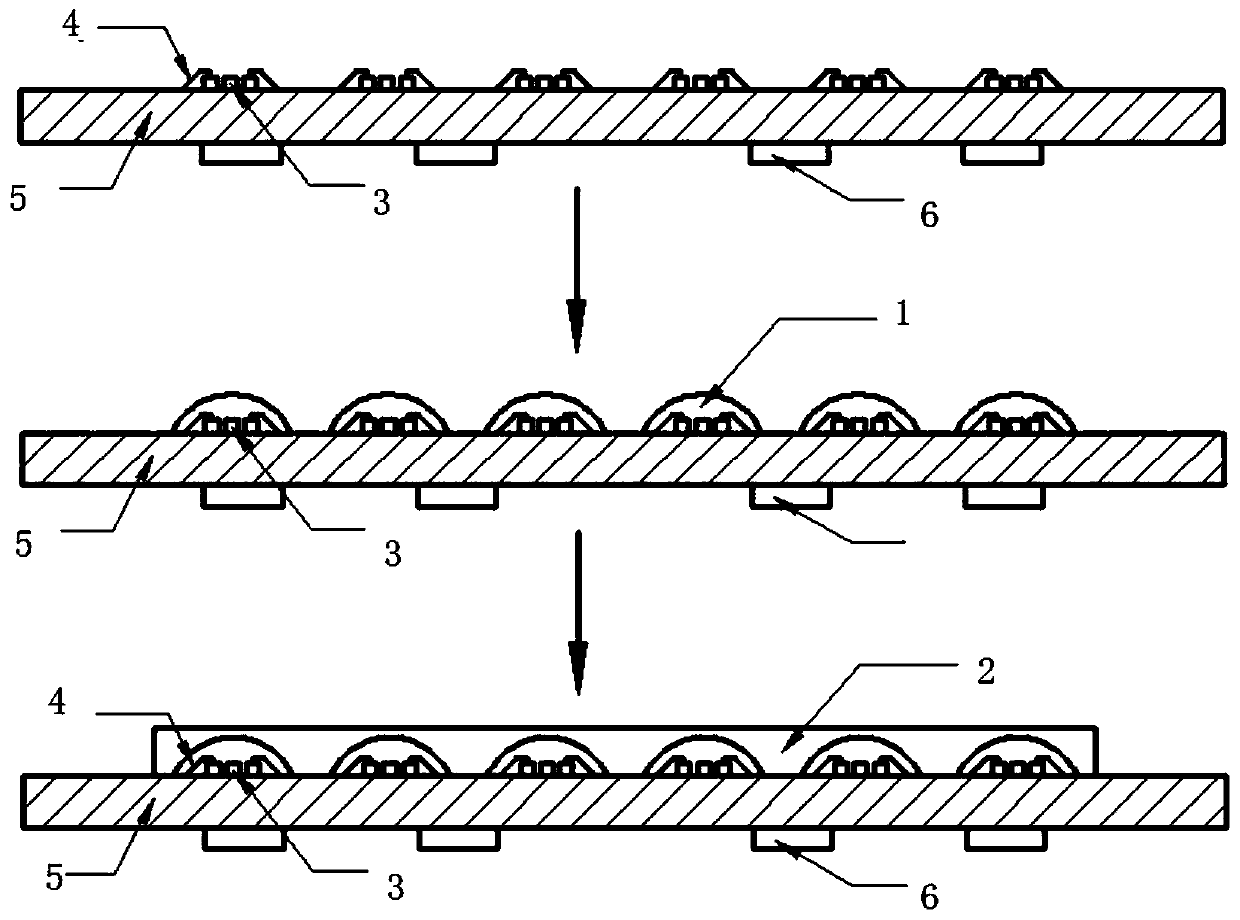

[0023] Such as Figure 1 to Figure 2 As shown, a high-performance COB display screen protected by double-layer packaging includes a circuit board (PCB) 5, an LED chip 3, a single-pixel packaging colloid 1 and an outer plane packaging colloid 2, and the LED chip 3 and the circuit board 5 conductive connection, an independent LED chip 3 is packaged in an independent single-pixel encapsulation compound 1, each of the LED chips 3 corresponds to one single-pixel encapsulation compound 1, and the outer plane package The colloid 2 is encapsulated outside all the single-pixel encapsulating colloids 1 , the single-pixel encapsulating colloid 1 is epoxy-based colloid, and the outer-plane encapsulating colloid 2 is silicone-based colloid or epoxy-modified colloid.

[0024] Such as Figure 1 to Figure 2 As shown, the single-pixel encapsulants 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com