Manufacturing method and using method of water-soluble liquid rosin and sulfur pesticide

A technology of water-soluble liquid and rosin, which is applied in the direction of botany equipment and methods, applications, chemicals for biological control, etc., can solve the problems of poisoning and aggravating pesticides, improve the absorption rate, prevent natural pests, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

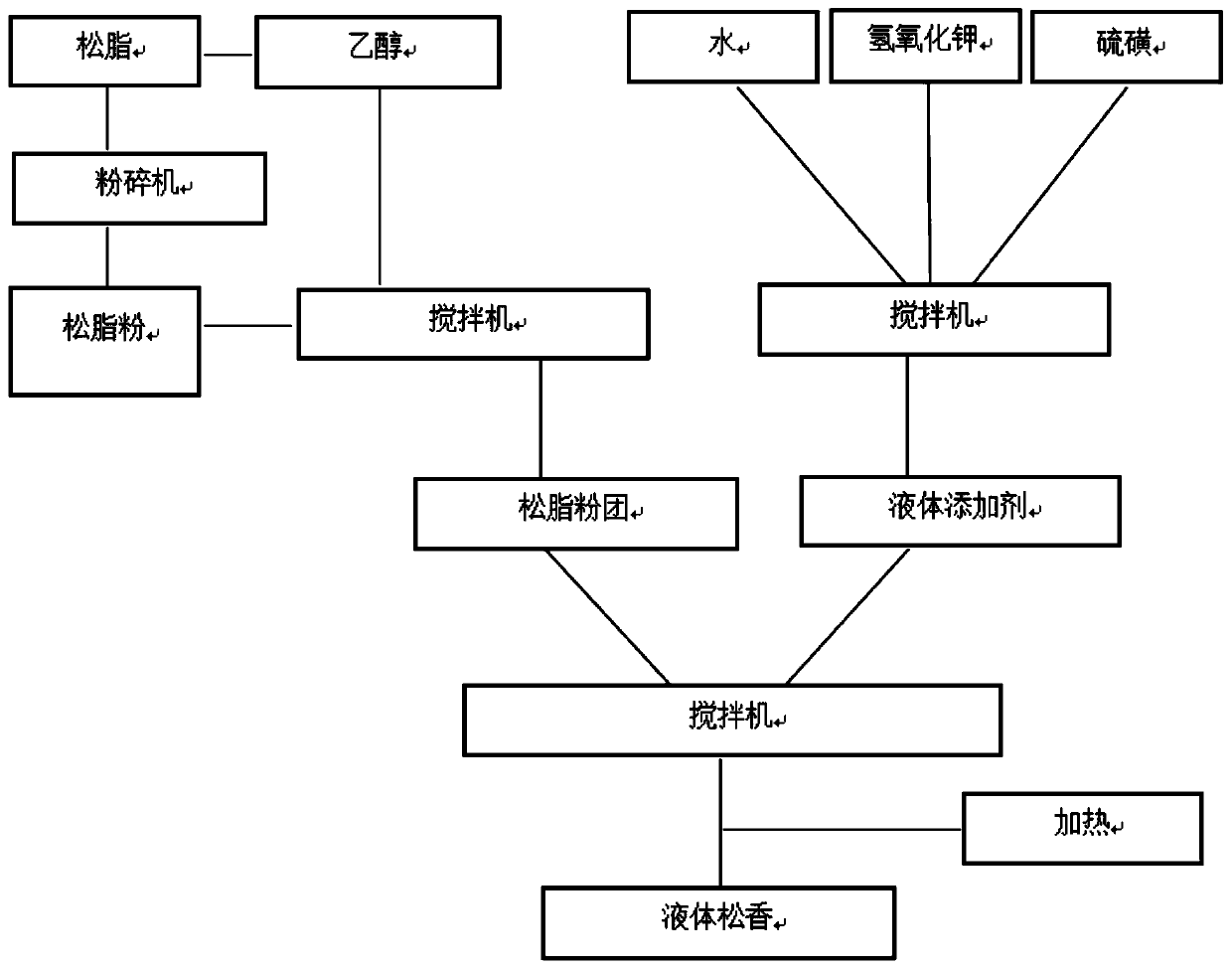

Image

Examples

Embodiment 1

[0033] Water-soluble liquid turpentine sulfur, water-soluble liquid turpentine sulfur is composed of turpentine batter A component and additive B component in proportion;

[0034] Wherein the specific ratio of component A of the turpentine batter is 25% of turpentine powder and 20% of ethanol;

[0035] The specific proportion of additive B component is 50 parts by weight of water, 3% of potassium hydroxide and 5% of sulfur.

Embodiment 2

[0037] Water-soluble liquid turpentine sulfur, water-soluble liquid turpentine sulfur is composed of turpentine batter A component and additive B component in proportion;

[0038] Wherein the specific proportioning ratio of component A of the turpentine batter is 40% of turpentine powder and 15% of ethanol;

[0039] The specific ratio of the additive B component is 40% of water, 7% of potassium hydroxide and 2% of sulfur.

Embodiment 3

[0041] Water-soluble liquid turpentine sulfur, water-soluble liquid turpentine sulfur is composed of turpentine batter A component and additive B component in proportion;

[0042] Wherein the specific proportioning ratio of component A of the turpentine batter is 50% of turpentine powder and 10% of ethanol;

[0043] The specific ratio of additive B component is 30% of water, 10% of potassium hydroxide and 1% of sulfur.

[0044] in,

[0045] Turpentine powder is obtained by grinding and stirring solid turpentine.

[0046] Ethanol is high-purity ethanol with a concentration exceeding 99%.

[0047] Water-soluble liquid turpentine sulfur manufacture method, concrete steps are as follows:

[0048] Wherein the specific preparation steps of component A are as follows:

[0049] a) putting solid turpentine into a blender for stirring and pulverizing to prepare turpentine powder;

[0050] b) put the corresponding proportion of turpentine powder and ethanol into the blender, fully m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com