Covalent organic framework membrane material and preparation method thereof

A technology of covalent organic frameworks and membrane materials, applied in the field of membrane separation, can solve the problems such as the inability to meet the needs of dye separation and the limited types of membrane materials, and achieve enhanced filtration and antibacterial properties, highly ordered, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

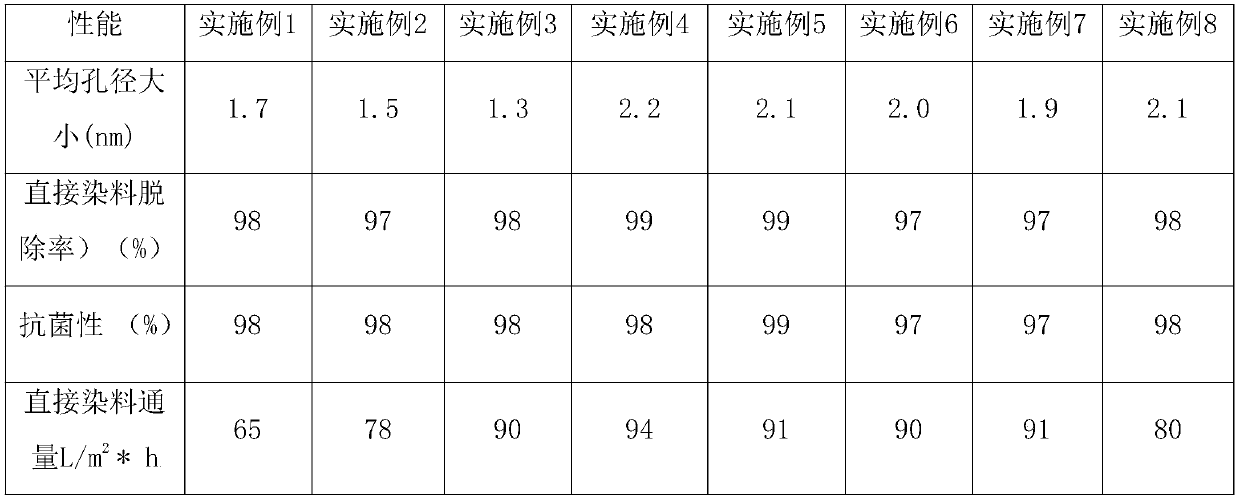

Examples

Embodiment 1

[0015] Add 16.6 parts of p-phenylenediamine, 10 parts of p-toluenesulfonic acid, 30 parts of distilled water in the beaker, stir for 5 minutes, then add 26 parts of trimethoxybenzenetrialdehyde, after stirring for 10 minutes, a mixed solvent is obtained, and the mixed solvent Spread it on a glass plate; program the temperature at 100°C and maintain it for 12 hours. After the mixed solvent is volatilized and dried, a film is obtained. Put the glass plate with the film in water, the film will peel off naturally, wash with distilled water several times, and dry for later use. .

Embodiment 2

[0017] Add 17.6 parts of dimethyl-p-phenylenediamine, 10 parts of p-toluenesulfonic acid, and 30 parts of distilled water in a beaker, stir for 5 minutes, then add 26 parts of m-trimethoxybenzenetrialdehyde, and stir for 10 minutes to obtain a mixed solvent. Spread the mixed solvent on a glass plate; program the temperature at 100°C and maintain it for 12 hours. After the mixed solvent evaporates and dries, a film is obtained. Put the glass plate with the film in water, the film will peel off naturally, and wash several times with distilled water , dry for later use.

Embodiment 3

[0019] Add 20.1 parts of dimethoxy-p-phenylenediamine, 10 parts of p-toluenesulfonic acid, and 30 parts of distilled water into a beaker, stir for 5 minutes, then add 26 parts of m-trimethoxybenzenetrialdehyde, and stir for 10 minutes to obtain a mixed solvent , spread the mixed solvent on a glass plate; the programmed temperature is maintained at 100°C for 12 hours, after the mixed solvent is volatilized and dried, a film is obtained, the glass plate with the film is put into water, the film is naturally peeled off, and washed with distilled water for several times, dry for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com