Intelligent control system of transformers and coolers based on comprehensive perception and working method thereof

An intelligent control system, intelligent control technology, applied in transformer/inductor cooling, control/regulation system, non-electric variable control and other directions, can solve the problems of large starting current, low degree of automation, and many mechanical contacts, and achieve speed Fast, wide protection range, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

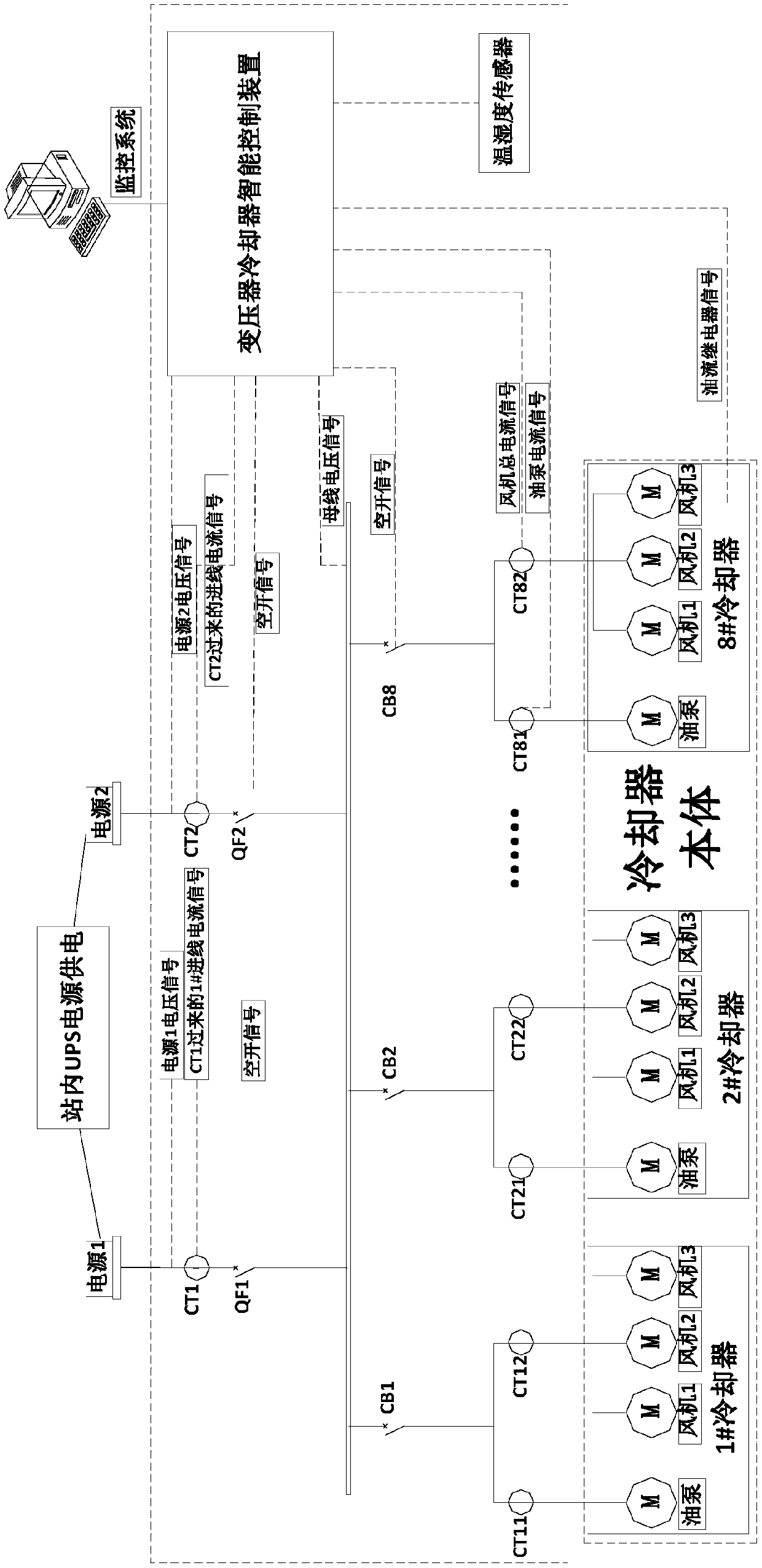

[0031] Such as figure 1 As shown, it shows the specific implementation of the present invention, based on the intelligent control system of transformer coolers with comprehensive perception, including multiple coolers, power supply I, power supply II, power supply I and power supply II are powered by UPS power supply in the station; power supply I And the power supply II is connected to all cooler circuits through the bus bar; it is characterized in that: the connection circuits between the power supply I, the power supply II and the bus bar are all equipped with feed-through transformers and air switches; the connection circuits between the bus bar and the cooler are all equipped with air switch; the connection circuit between the bus bar and the cooler includes the main circuit and two branch circuits connected in parallel on the main circuit; an air switch is installed on the main circuit, and wear-through Heart transformer;

[0032] It also includes an intelligent control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com