Trailing suction hopper dredger operation parameter learning method

A technology of trailing suction dredger and operating parameters, which is applied in neural learning methods, biological neural network models, design optimization/simulation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

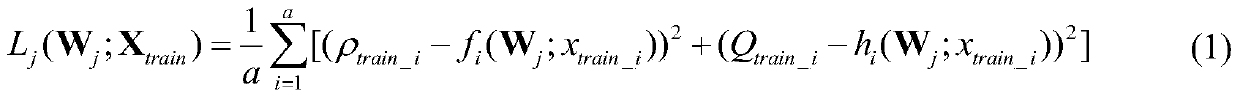

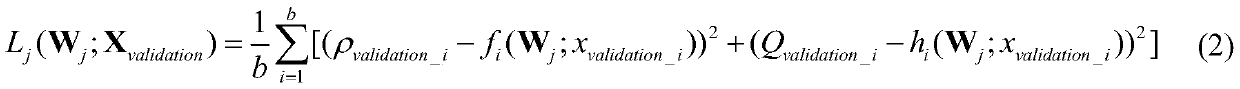

[0060] A learning method for operating parameters of a trailing suction dredger. The learning method steps of the present embodiment are:

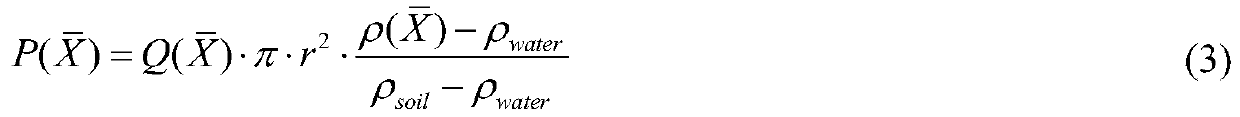

[0061] Step 1. According to the 640512 original data groups of the trailing suction dredger provided by the trailing suction dredger operator. Determine the characteristic data and measurement data in each original data group, the characteristic data are speed over ground v, compensator pressure F, active rake head angle θ h and the vertical angle θ of the lower rake tube ver Four parameters, the measurement data are two parameters of mixture density ρ and mixture flow rate Q.

[0062] Step 2. Eliminate the data groups with mixture density ρ<1.025 in the original data group to obtain 625,608 effective data groups with mixture density ρ≥1.025, and randomly select 600,000 effective data groups (see Table 1 for details). Each payload data group contains characteristic payload x and measurement payload y. The data set consisting of 600,000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com