Microporous layer structure, preparation method, membrane electrode assembly and fuel cell

A membrane electrode assembly and fuel cell technology, which is applied to fuel cells, fuel cell parts, electrical components, etc., can solve the problems of increased reaction gas transfer resistance, mass transfer polarization loss, etc., to reduce overall costs and increase volume The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

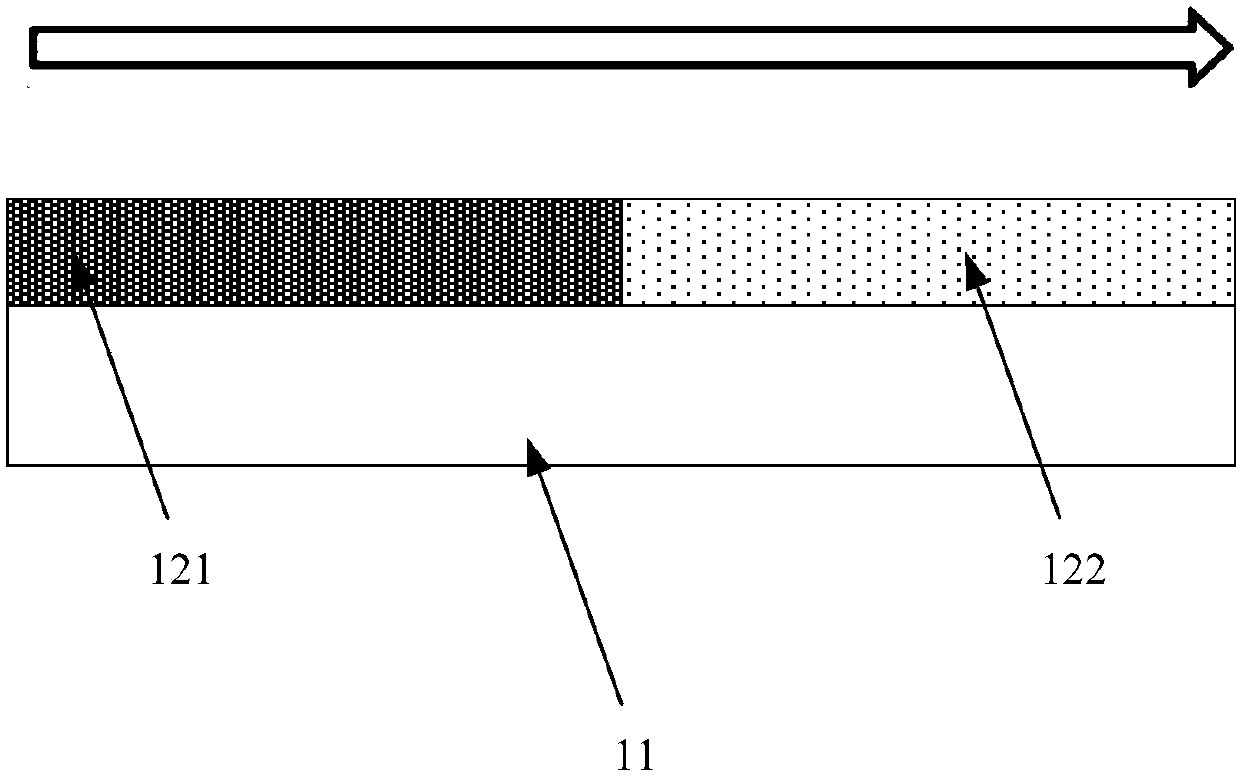

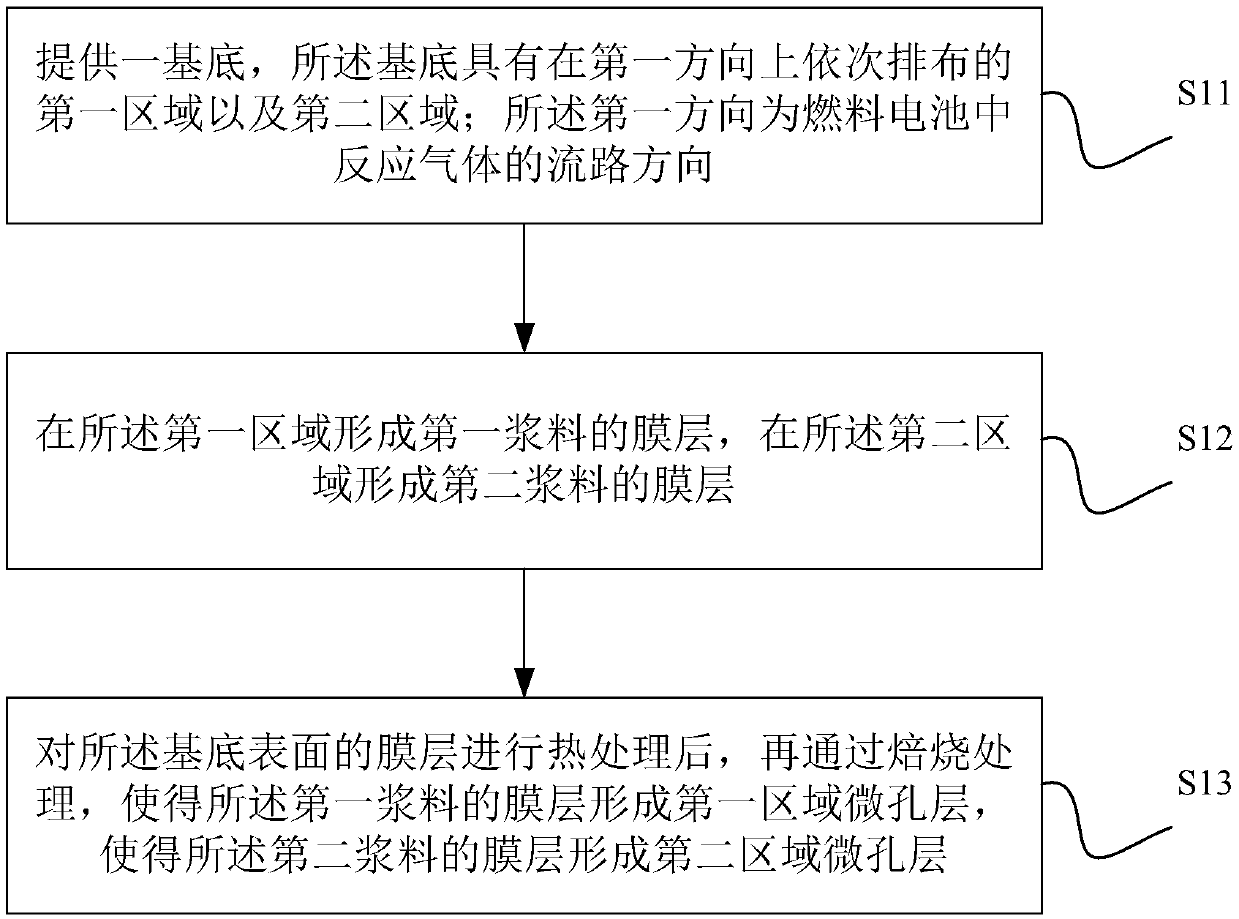

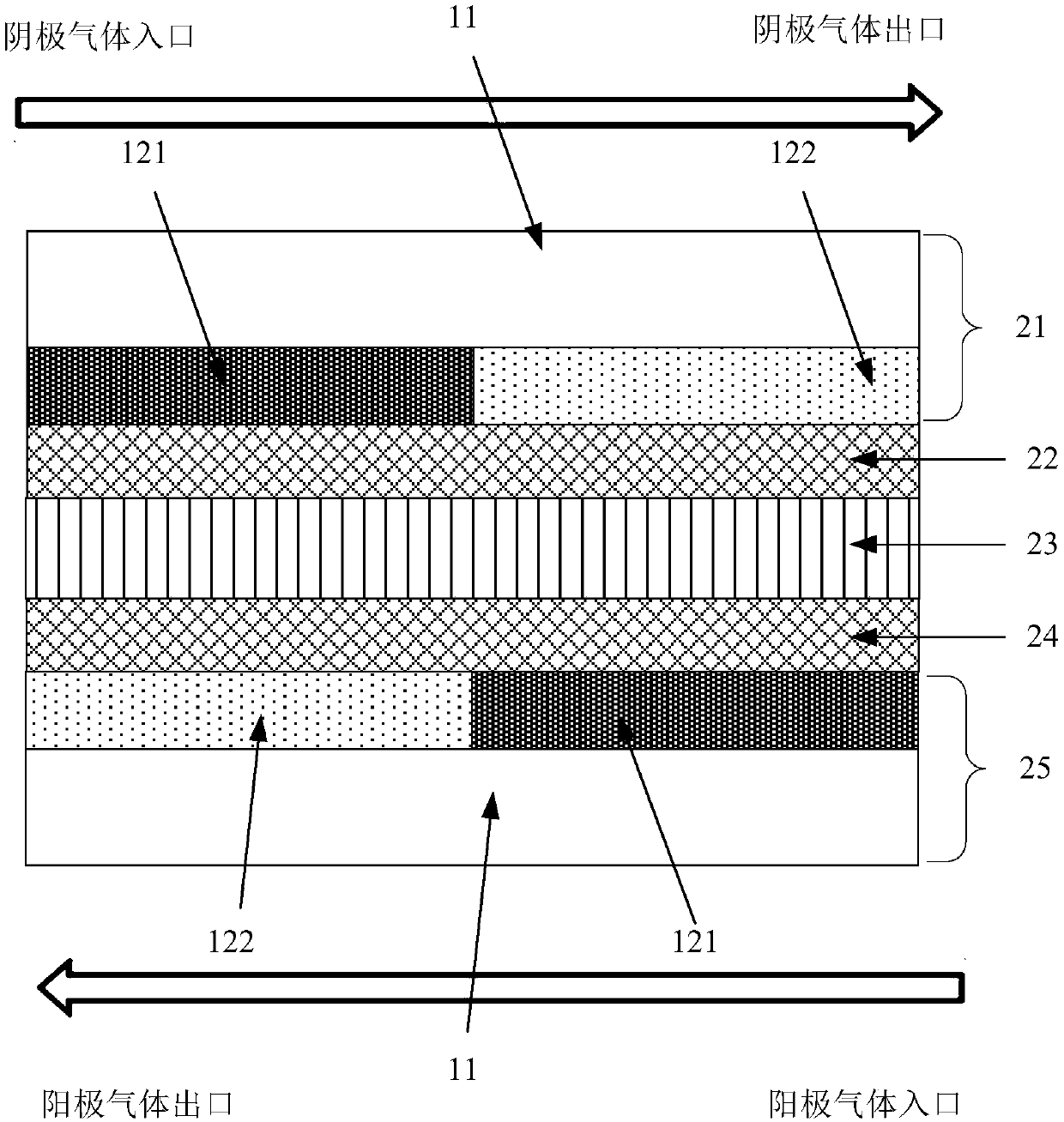

[0069] The preparation method of the microporous layer structure is simple, only need to change the amount of pore-forming agent in the slurry, and control the porosity of different regions, so as to achieve the purpose of fuel cell stack water balance. Specifically, the microporous layer 121 in the first region is prepared from the first slurry; the microporous layer 122 in the second region is prepared from the second slurry; the content of the pore-forming agent in the first slurry is less than the specified Describe the content of pore-forming agent in the second slurry.

[0070] The membrane electrode assembly designed with the microporous layer structure and the prepared fuel cell stack have the effect of improving the water balance on both sides of the cathode and anode for the reaction gas flow direction of the cathode and anode in a convection mode.

[0071] Based on the above embodiment, another embodiment of the present invention also provides a capital method for p...

other Embodiment approach

[0074] In other embodiments, the pre-prepared first slurry or the second slurry may also be used. The ratio of each component in the slurry is set according to the required porosity and water vapor transmission rate, and the ratio of each component is not specifically limited in this application. The first slurry needs to be stirred to make the components uniformly mixed, and the second slurry also needs to be stirred to make the components evenly mixed.

[0075] The conductive material is carbon black, preferably Vulcan XC-72(R) or Acetylene Black. The pore-forming agent includes one or both of ammonium carbonate, ammonium oxalate and lithium carbonate, preferably ammonium oxalate. The hydrophobic agent is polytetrafluoroethylene aqueous dispersion. The dispersion liquid is alcohols, and the alcohols include one or both of ethanol, isopropanol and ethylene glycol, preferably isopropanol.

[0076] Step S12: forming a film layer of the first slurry in the first region, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com