Transmission mechanism for spaceflight

A transmission mechanism, permanent magnet technology, applied in electromechanical devices, electric components, electric brakes/clutches, etc., can solve the problems of friction loss, lubrication pollution, mechanical fatigue, etc., and achieve the effect of stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

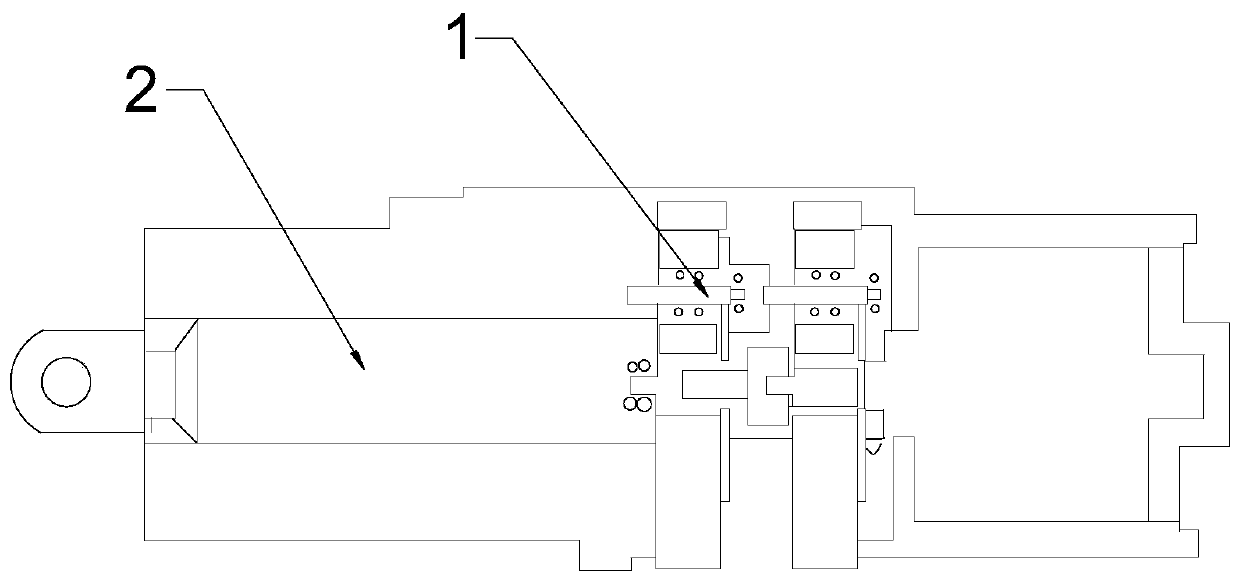

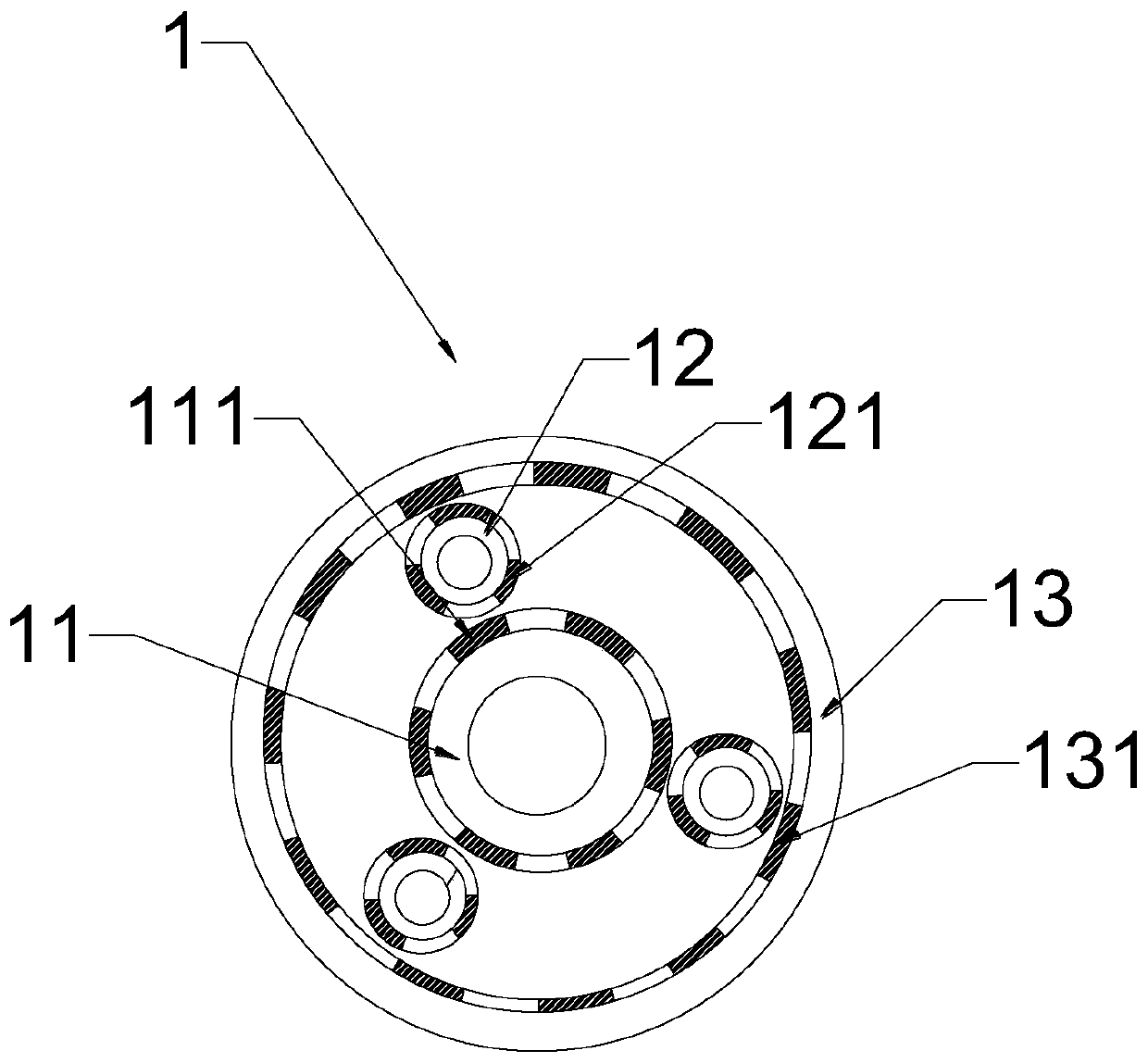

[0039] combine Figure 1-2 , a transmission mechanism for aerospace, including a planetary gear set 1 and a ball screw pair 2, the ball screw pair 2 is connected to the planetary gear set 1, and the planetary gear set 1 and the ball screw pair 2 are linear Arranged, the planetary gear set 1 includes a sun gear 11, a planetary gear 12, an inner ring gear 13 and a permanent magnet. The rotation direction of the meshing gear is opposite. The planetary gear 12 and the ring gear 13 are ring gear structures. The rotation direction of the planetary gear 12 and the ring gear 13 is the same. Axis settings.

[0040] Described permanent magnet comprises the first permanent magnet 111 of radial magnetization, the second permanent magnet 121 and the 3rd permanent magnet 131, and the outer surface of described sun gear 11 is provided with first permanent magnet 111, and the outer surface of described planetary gear 12 The second permanent magnet 121 is arranged on the surface, and the thi...

Embodiment 2

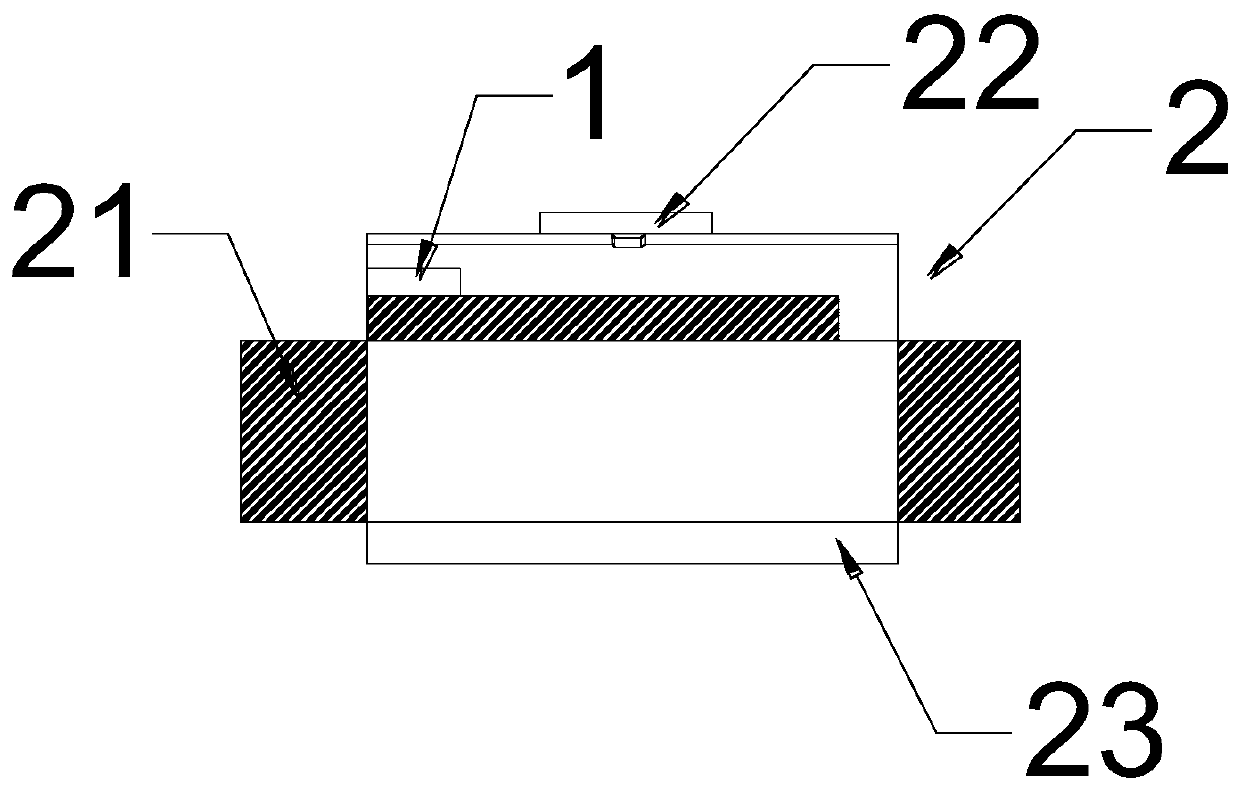

[0043] combine figure 1 and image 3 , the ball screw pair 2 includes a roller screw 21, a nut 23 and a flat key 22, one end of the roller screw 21 is connected to the planetary gear set 1, the nut 23 is sleeved on the ball screw, the The flat key 22 is arranged on the nut 23, and the nut 23 adopts a combined double nut 23 composed of two nuts 23 without axial clearance.

[0044] Combine the planetary gear set 1 and the ball screw pair 2, and drive the planetary gear set 1 through the motor. The planetary gear set 1 is equivalent to the reducer of the ball screw pair 2, so that the screw runs more smoothly and realizes the ball screw pair 2. The different transmission ratios make the ball screw 21 have a strong bearing capacity and life span, and have higher rotational speed and angular acceleration, which can be applied to various conditions and realize the miniaturization and light weight of the transmission mechanism.

Embodiment 3

[0046] On the basis of Embodiment 1, the planetary gear is connected to the planetary carrier, and the sun gear, the planetary carrier and the internal gear are coaxially arranged.

[0047] The sun gear radius R 1 , planet wheel radius R 2 and ring gear radius R 3 Meet: R 1 +2R 2 = R 3 .

[0048] The number of pole pairs of the sun gear P 1 , Planetary gear pole pair number P 2 and the number of pole pairs of the inner ring gear P 3 Satisfied:P 1 +2P 2 =P 3 .

[0049] The radius of the planet carrier satisfies: R 4 =(R 3 +R 1 ) / 2.

[0050] The number of the planetary wheels satisfies: in And a, b∈N, 1≤N≤4.

[0051] The sun gear angular velocity ω 1 , planet carrier angular velocity ω 4 and the angular velocity of the ring gear ω 3 satisfy:

[0052] The angular velocity of the ball screw ω G satisfy: Among them, d 1 is the screw diameter, d 2 is the nut diameter.

[0053] Both the planetary gear and the sun are pasted with magnetic pieces on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com