Microcapsule for improving immunity of patients with chronic diseases and preparation method of microcapsule

A technology for chronic diseases and immunity, applied in the formation of food, the function of food ingredients, and food ingredients containing oil, etc., can solve the problems of increasing social and family economic burden, affecting labor ability and quality of life, and expensive medical expenses. Good oxidative stability, high food value, and less loss of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

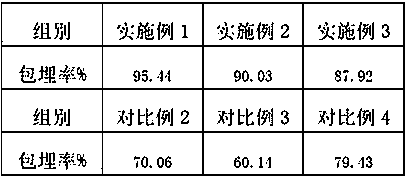

Embodiment 1

[0029] The preparation process of the core material: first add the chia seed oil into the container, then add the chia seed powder, and mix thoroughly; make an emulsion, pack and store at an appropriate temperature.

[0030] A preparation process of microcapsules for improving the immunity of patients with chronic diseases: Weighing 20g of sorghum starch, 18g of high amylose corn starch, 31.15g of maltodextrin, 1.5g of monoglyceride and 0.5g of chia seed gum, fully stirred at 65°C Dissolve to 500mL; then add 28.85g of core material, and shear at high speed for 5 minutes under the condition of 10000 rpm; use a high-pressure homogenizer to homogenize the above emulsion, the condition is 30MPa, homogenize 3 times; finally spray dry The inlet temperature is 175-180°C, the outlet temperature is 95-100°C, and the feed rate is 5-8mL / min.

Embodiment 2

[0032] Preparation of the core material: The preparation process of the core material: first add the chia seed oil into the container, then add the chia seed powder, mix thoroughly; make an emulsion, pack and store at an appropriate temperature.

[0033] A preparation process of microcapsules to improve the immunity of patients with chronic diseases: Weigh 10g of sorghum starch, 10g of high amylose corn starch, 48g of maltodextrin, 1.55g of monoglyceride and 0.45g of chia seed gum, and fully stir and dissolve at 65°C to 500mL; then add 30g of core material, and shear at high speed for 5 minutes under the condition of 10,000 rpm; use a high-pressure homogenizer to homogenize the above-mentioned emulsion under the condition of 30MPa, and homogenize 3 times; finally, the inlet temperature of spray drying 175-180°C, outlet temperature 95-100°C, feed rate 5-8mL / min.

Embodiment 3

[0035] The preparation process of the core material: first add the chia seed oil into the container, then add the chia seed powder, and mix thoroughly; make an emulsion, pack and store at an appropriate temperature.

[0036] A preparation process of microcapsules for improving the immunity of patients with chronic diseases: Weigh 10g of sorghum starch, 30g of high amylose corn starch, 18g of maltodextrin, 1g of monoglyceride and 1g of chia seed gum, and fully stir and dissolve to 500mL at 65°C Add 40g of core material again, and shear at high speed for 5 minutes under the condition of 10000 rpm; use a high-pressure homogenizer to homogenize the above-mentioned emulsion, the condition is 30MPa, and homogenize 3 times; the final spray drying inlet temperature is 175- 180°C, outlet temperature 95-100°C, feed rate 5-8mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com