Rotary nozzle ring capable of reducing ventilation resistance for medium-speed coal pulverizer

A technology of rotating nozzles and ventilation resistance, which is applied in the direction of grain processing, etc. It can solve the problems of low service life of nozzle ring blades, wear of weighted roller bracket guard plate, and different degrees of blade wear, so as to reduce maintenance costs and facilitate replacement and installation. , Reduce the effect of scouring wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

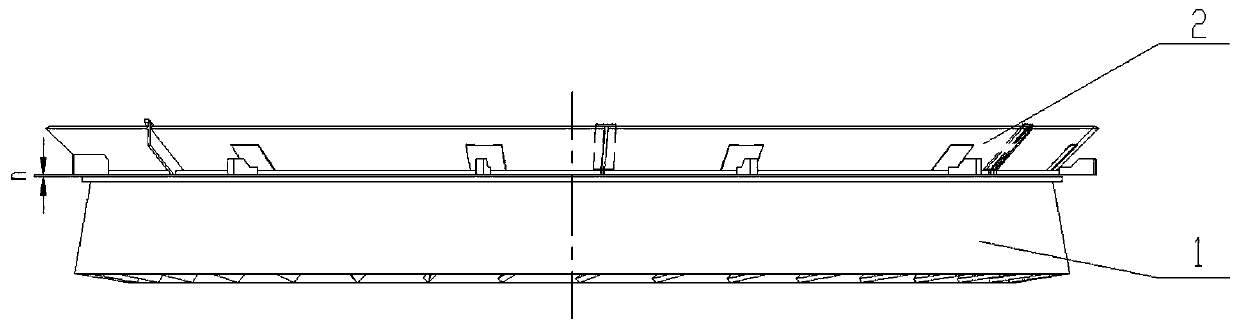

[0019] refer to figure 1 , the present invention reduces the ventilation resistance of a medium-speed coal mill rotating nozzle ring, which is composed of a moving nozzle ring 1 and a static nozzle ring 2,

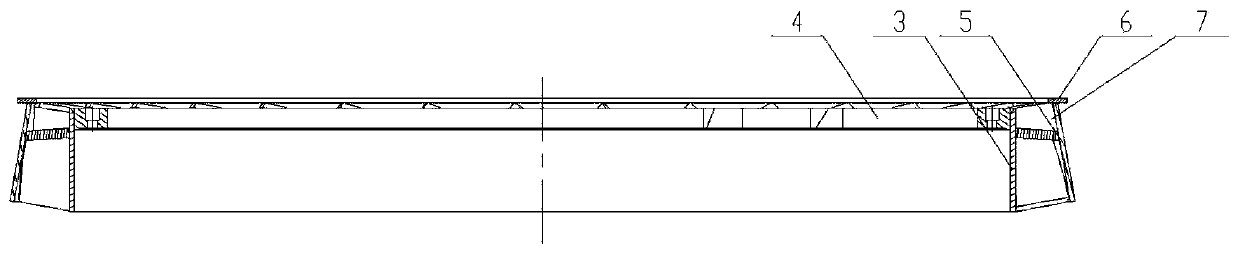

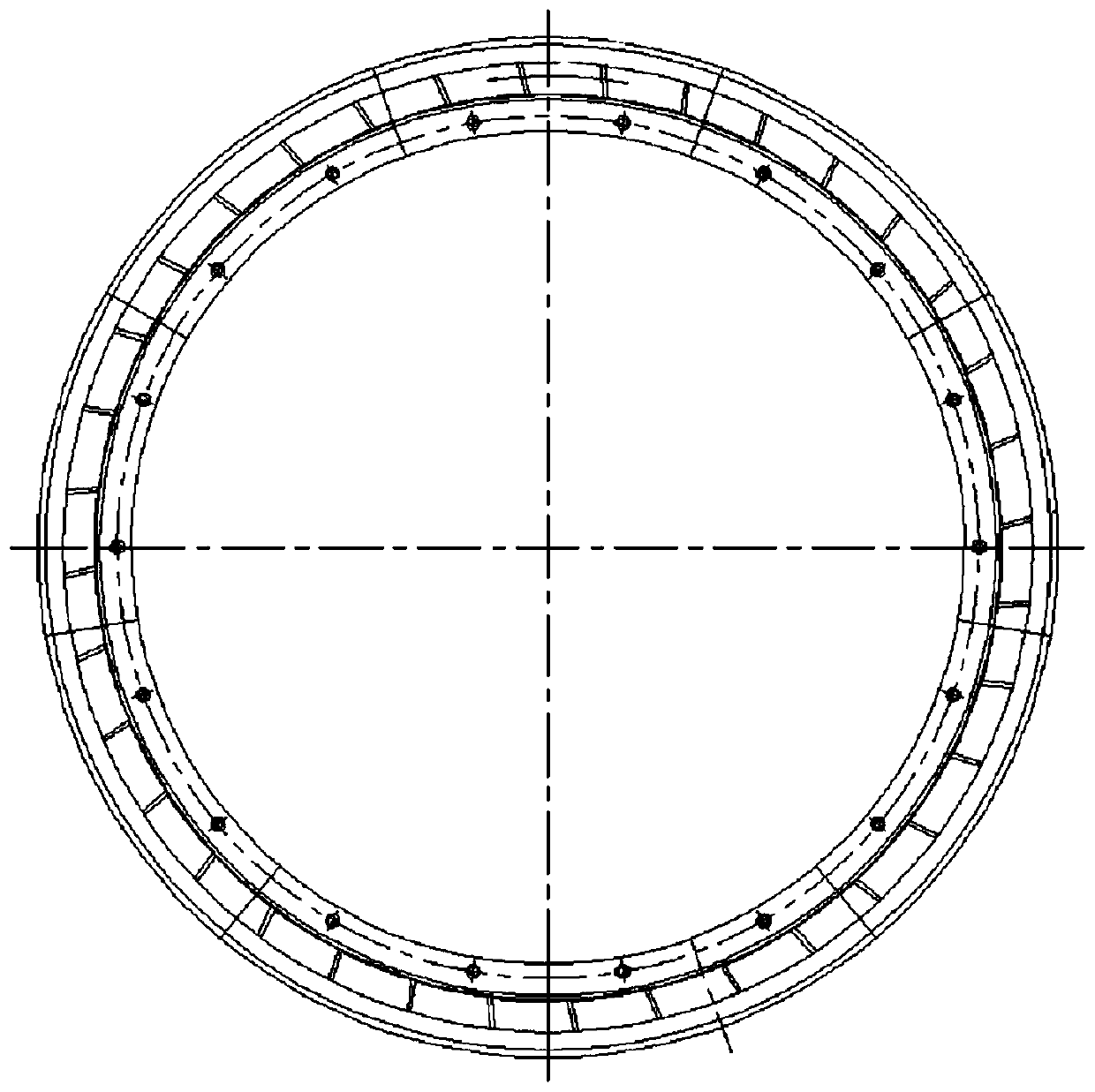

[0020] refer to figure 2 , image 3 , the movable nozzle ring includes: a straight inner wall plate 3 surrounding the inner wall plate, a frustum-shaped outer wall plate 5, a blade 7 welded between the inner wall plate and the outer wall plate, welded on the inner wall plate The top of the plate, the flat flange 4 located in the circumference of the inner plate, is welded on the upper end of the outer wall plate, and the annular top plate 6 extending into the part of the annular gap between the inner wall plate and the outer wall plate; the movable nozzle ring is used to pass through the flange. The bolt connection is fixed on the grinding disc of the medium-speed coal mill. Wherein, the clamping between the blade 7 and the horizontal plane is 40°~60°, and the upper en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com