Process for preparing pressed high borosilicate glass product

A high borosilicate glass and preparation technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as opening micro-cracks, and achieve the effects of improving the pass rate, ingenious process design, and reasonable optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

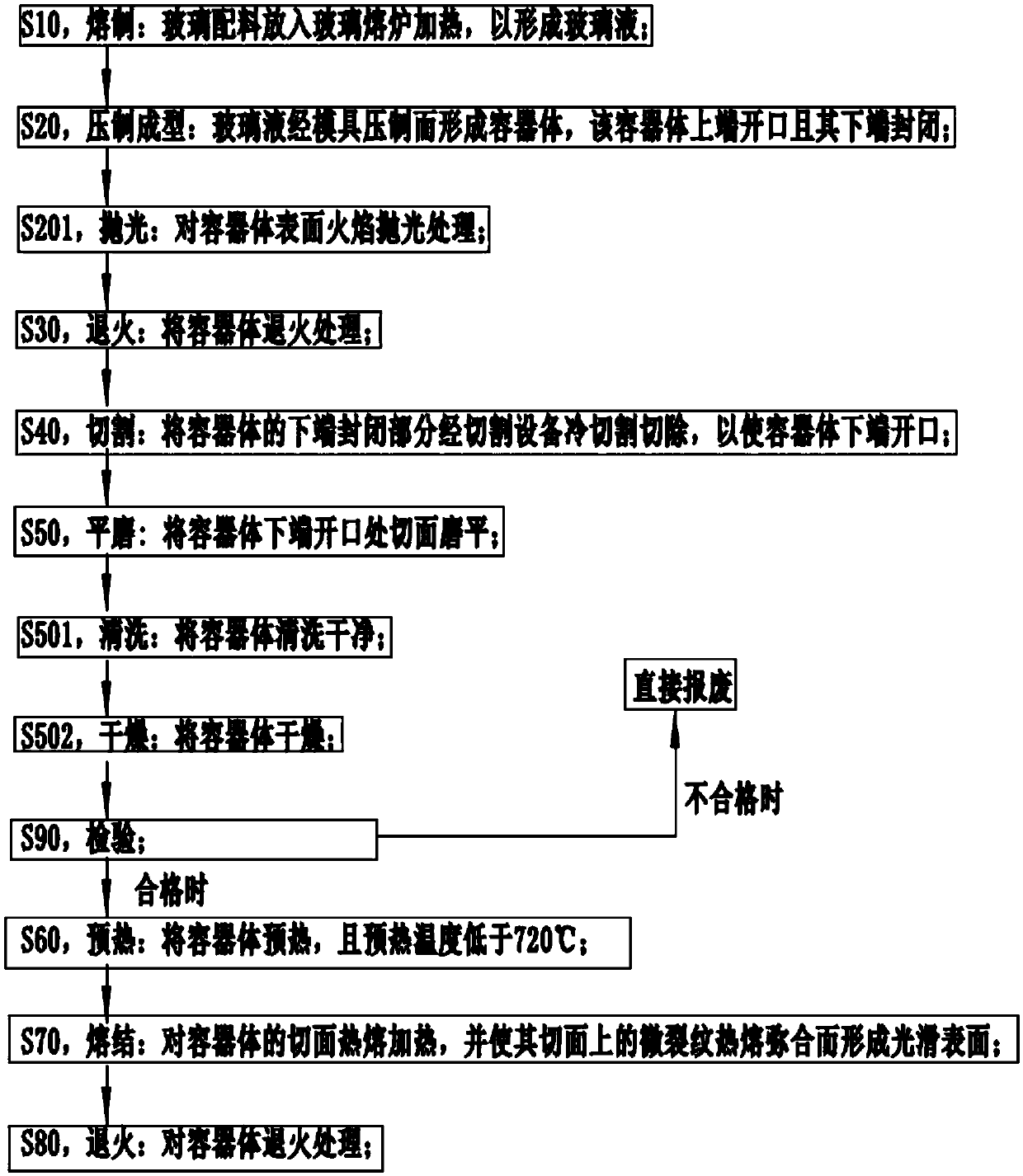

[0037] Example: see figure 1 , a preparation process of pressed borosilicate glass products, comprising the steps of:

[0038] S10, melting: the glass ingredients are put into a glass melting furnace and heated to form glass liquid;

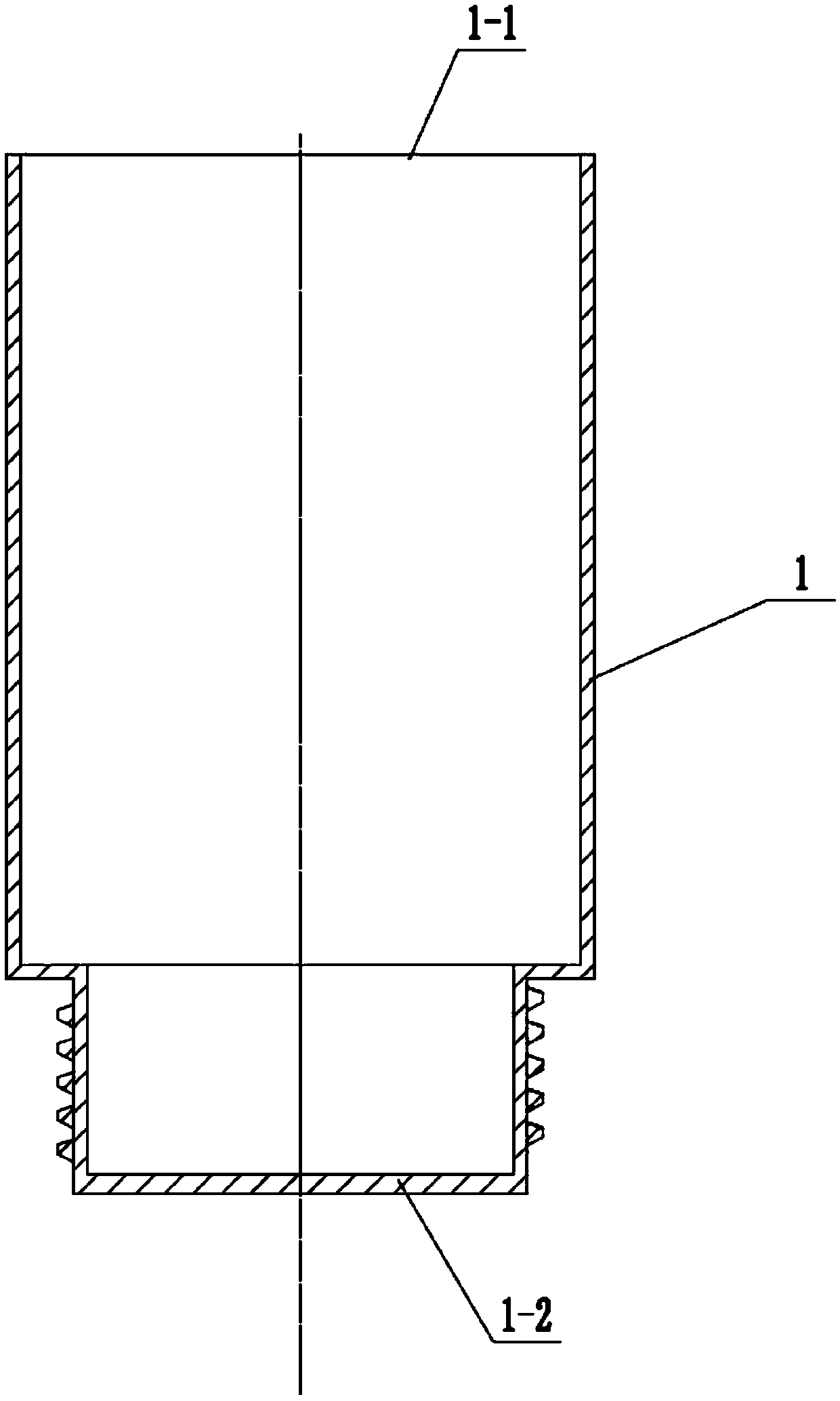

[0039] S20, press molding: the molten glass is pressed by a mold to form a container body 1, the upper end of the container body 1 is open 1-1 and its lower end is closed, that is, the lower end of the container body 1 has a closed part 1-2 (see figure 2 );

[0040] S201, polishing: flame polishing treatment on the surface of the container body.

[0041] S30, annealing: annealing the container body;

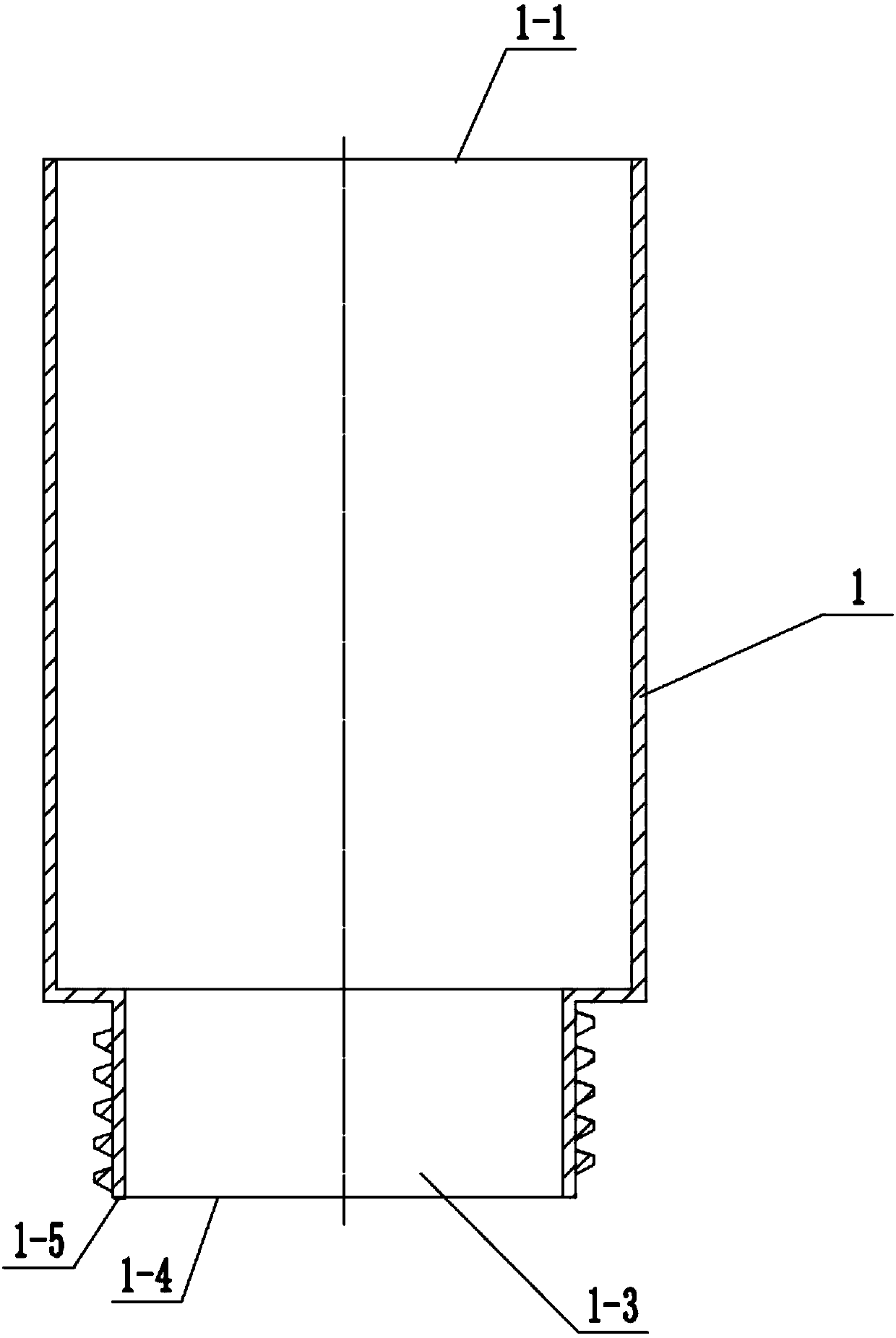

[0042] S40, cutting: the lower end of the container body is closed part 1-2 (see figure 2 ) is cold cut and removed by cutting equipment (such as a water-cooled cutting machine), so that the lower end of the container body is opened 1-3 (see Figure 3-4 );

[0043] S50, flat grinding: grinding the cutting surface 1-4 at the opening of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com