Gas temperature sensor and manufacturing method thereof

A gas temperature and sensor technology, applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve the problems of poor welding performance of high-temperature alloys, fatigue fracture of thermocouple wires, and difficult discharge of gas at the temperature-measuring end and other problems to achieve the effect of improving high pressure resistance and preventing thread loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

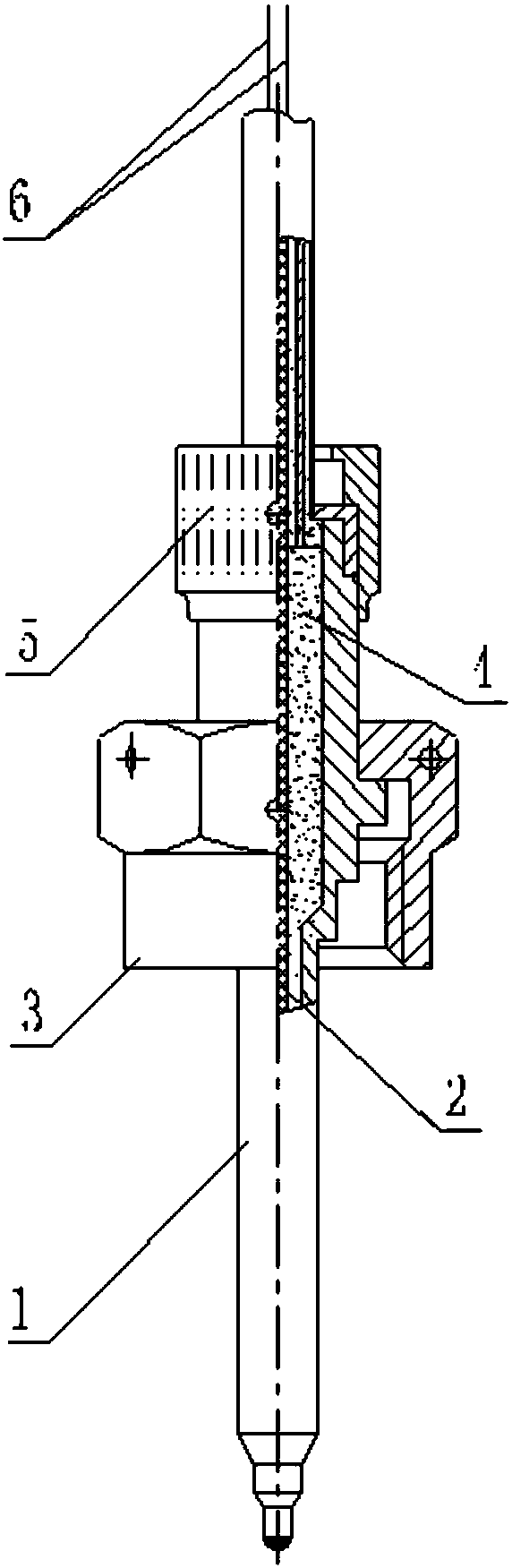

[0030] Such as figure 1 Shown: the present invention provides a kind of gas temperature sensor including housing 1, two thermocouple wires 6, glass frit 4, pressure sleeve 5 and non-alkali glass fiber casing 2; Wherein, the diameter of non-alkali glass fiber casing The diameter is 0.7mm, and its surface is smooth. The small diameter of the non-alkali glass fiber sleeve increases the potting space of the glass powder, which facilitates the glass powder to flow into the bottom of the shell.

[0031] In addition, in order to avoid the problem of microcracks when the pressure sleeve and the housing of the temperature sensor are fixed by welding, the upper end of the housing of the present invention is provided with external threads; thread; the pressure sleeve and the shell are fixed together through threaded connection; and the side wall of the pressure sleeve is provided with a through hole, the purpose is to use the through hole of the pressure sleeve to destroy the external th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com