A method for additive manufacturing of titanium alloy thin-walled parts

A technology of additive manufacturing and thin-walled parts, which is applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve problems such as microcracks, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

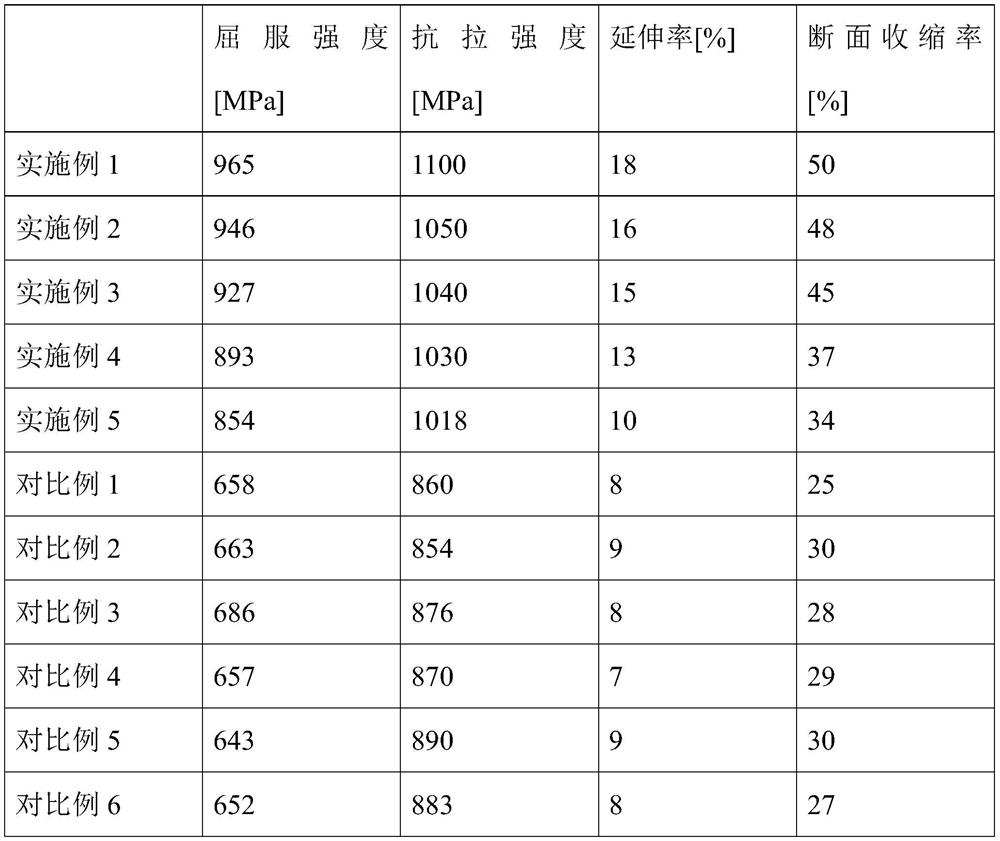

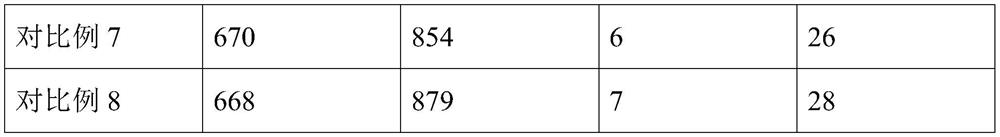

Examples

Embodiment 1

[0071] This embodiment provides a method for additive manufacturing of aerospace engine rudder wing thin-walled parts using TA15 titanium alloy powder. The content [wt%] of each element component in the titanium alloy powder is shown in the following table:

[0072] C Al Zr Mo V Fe Si O N H Ti ≤0.03 6.5 2 1.2 1.6 ≤0.1 ≤0.05 ≤0.08 ≤0.03 ≤0.0125 margin

[0073] The described additive manufacturing method comprises the steps:

[0074] (1) Carry out three-dimensional modeling according to the solid structure of thin-walled parts to obtain a solid model, add ribs on the outer surface of the solid model to obtain an additive model, design a 2mm hole at the connection between the rib and the solid model, and the distance between adjacent holes The hole spacing is 6mm, and the additive model is sliced and layered, and the slice thickness is 0.04mm;

[0075] (2) Baking the TA15 titanium alloy powder, the baking temperature is 100°C, and the ...

Embodiment 2

[0083] This embodiment provides an additive manufacturing method for preparing cabin parts using TA15 titanium alloy powder. The content [%] of each element component in the titanium alloy powder is shown in the following table:

[0084] C Al Zr Mo V Fe Si O N H Ti ≤0.03 7.2 1.5 1.5 1.3 ≤0.1 ≤0.05 ≤0.08 ≤0.03 ≤0.0125 margin

[0085] The described additive manufacturing method comprises the steps:

[0086] (1) Carry out three-dimensional modeling according to the solid structure of thin-walled parts to obtain a solid model, and add a lattice structure on the outer surface of the solid model to obtain an additive model. The rod diameter of the lattice structure unit cell is 0.4mm, and slice the additive model Layered, the slice thickness is 0.05mm;

[0087] (2) Baking the TA15 titanium alloy powder, the baking temperature is 120°C, and the holding time of the baking powder process is 6h;

[0088] (3) The preheating temperature of the s...

Embodiment 3

[0095] This embodiment provides an additive manufacturing method for preparing thin-walled parts of connecting joints by using TA15 titanium alloy powder. The content [%] of each element component in the titanium alloy powder is shown in the following table:

[0096] C Al Zr Mo V Fe Si O N H Ti ≤0.03 5.8 1.8 0.5 0.8 ≤0.1 ≤0.05 ≤0.08 ≤0.03 ≤0.0125 margin

[0097] The described additive manufacturing method comprises the steps:

[0098] (1) Carry out three-dimensional modeling according to the solid structure of thin-walled parts to obtain a solid model, add ribs on the outer surface of the solid model to obtain an additive model, design a 3mm hole at the connection between the rib and the solid model, and the distance between adjacent holes The hole spacing is 2mm, and the additive model is sliced and layered, and the slice thickness is 0.06mm;

[0099] (2) Baking the TA15 titanium alloy powder, the baking temperature is 125°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com