Environment-friendly asphalt mixture and preparation method thereof

An asphalt mixture, environmental protection technology, applied in the field of asphalt materials, can solve the problems of asphalt mixture deformation, cracking, road surface sag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

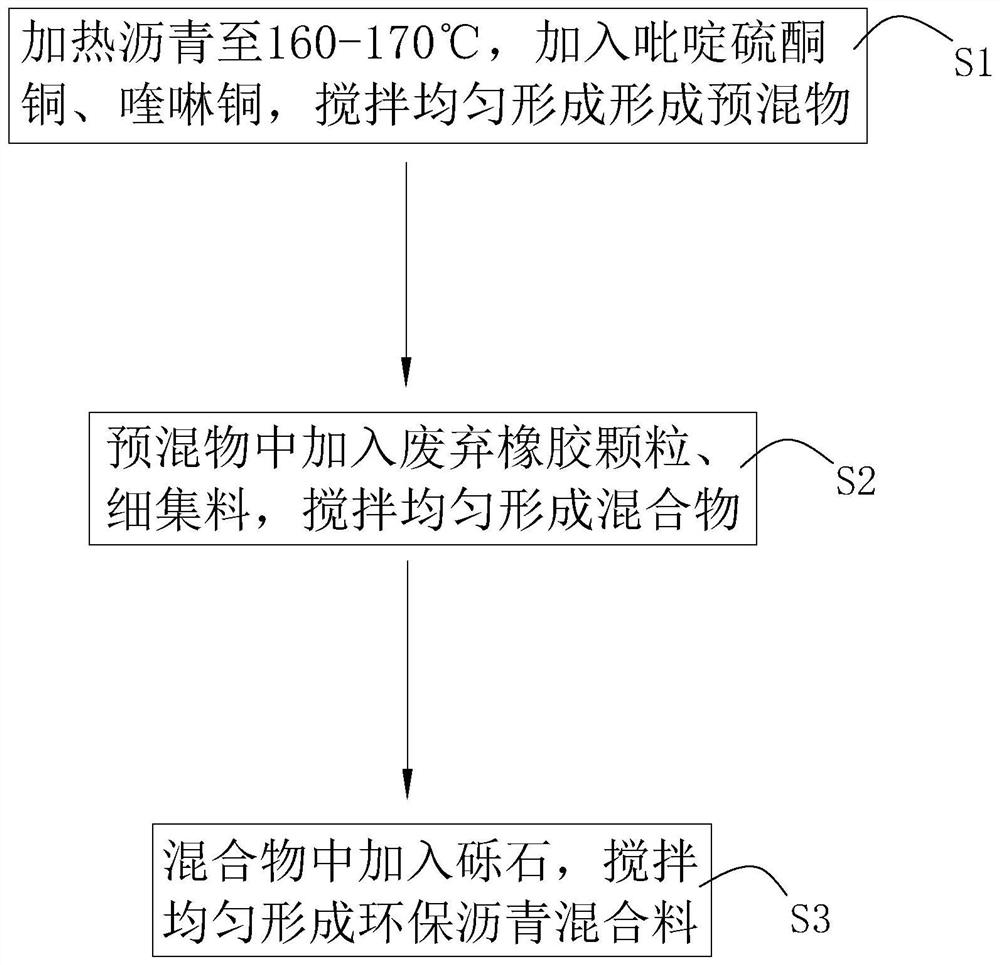

[0080] A kind of environment-friendly asphalt mixture, with reference to figure 1 , the preparation method of environment-friendly asphalt mixture comprises the following steps:

[0081] S1. Add 100kg of asphalt into the stirring tank, heat the asphalt to 160°C, add 5kg of copper pyrithione and 1kg of copper quinoline, keep the temperature at 160°C, rotate at 60r / min, and stir for 5min to form a premix.

[0082] S2. Add 100kg of waste rubber particles and 120kg of fine aggregates to the premixture, keep the temperature at 160°C, rotate at 50r / min, and stir for 10min to form a mixture.

[0083] S3. Add 150kg of gravel to the mixture, keep the constant temperature at 160°C, rotate at 40r / min, and stir for 10min to form an environmentally friendly asphalt mixture.

Embodiment 2

[0085] A kind of environment-friendly asphalt mixture, with reference to figure 1 , the preparation method of environment-friendly asphalt mixture comprises the following steps:

[0086] S1. Add 100kg of asphalt into the stirring tank, heat the asphalt to 165°C, add 6.5kg of copper pyrithione and 2kg of copper quinoline, keep the temperature at 165°C, rotate at 60r / min, and stir for 5min to form a premix.

[0087] S2. Add 110kg of waste rubber granules and 135kg of fine aggregate to the premix, keep the temperature at 165°C, rotate at 50r / min, and stir for 10min to form a mixture.

[0088] S3. Add 165kg of gravel to the mixture, keep the constant temperature at 165°C, rotate at 40r / min, and stir for 10min to form an environmentally friendly asphalt mixture.

Embodiment 3

[0090] A kind of environment-friendly asphalt mixture, with reference to figure 1 , the preparation method of environment-friendly asphalt mixture comprises the following steps:

[0091] S1. Add 100kg of asphalt into the stirring tank, heat the asphalt to 170°C, add 8kg of copper pyrithione and 3kg of copper quinoline, keep the temperature at 170°C, rotate at 60r / min, and stir for 5min to form a premix.

[0092] S2. Add 120kg of waste rubber granules and 150kg of fine aggregate to the premix, keep the temperature at 170°C, rotate at 50r / min, and stir for 10min to form a mixture.

[0093] S3. Add 180kg of gravel to the mixture, keep the constant temperature at 170°C, rotate at 40r / min, and stir for 10min to form an environmentally friendly asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com