Organic fertilizer taking coffee grounds as main raw material, and aerobic composting process and application of organic fertilizer

An aerobic composting and organic fertilizer technology, applied in the field of resource utilization and composting, can solve the problems of unfavorable agricultural production and direct utilization, and achieve the effects of reducing the risk of salinization, improving the degree of decomposition, and good repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] An organic fertilizer with coffee grounds as the main raw material. The raw material components include: coffee grounds 89.5%, formulation A urea 1.4% and formulation B rice husk 9.1%.

[0075] The aerobic composting process of the above-mentioned organic fertilizer with coffee grounds as the main raw material, the steps are as follows:

[0076] (1) Ingredients: According to the formula ratio, take coffee grounds and blending agent A and mix thoroughly, add water to adjust the moisture content of the mixture to 55%, and the carbon-nitrogen ratio to 25; continue to add rice husks with a moisture content of 55%, to obtain a premix materials;

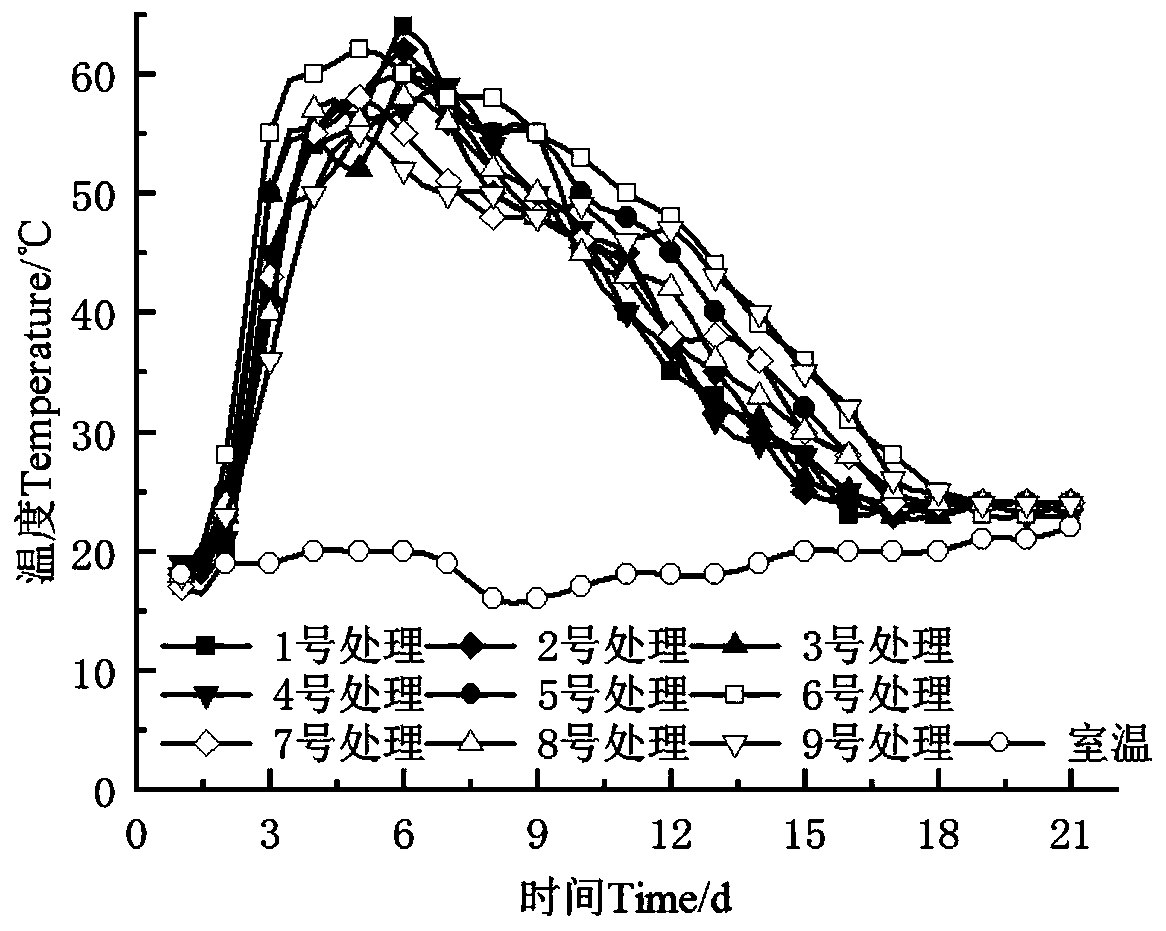

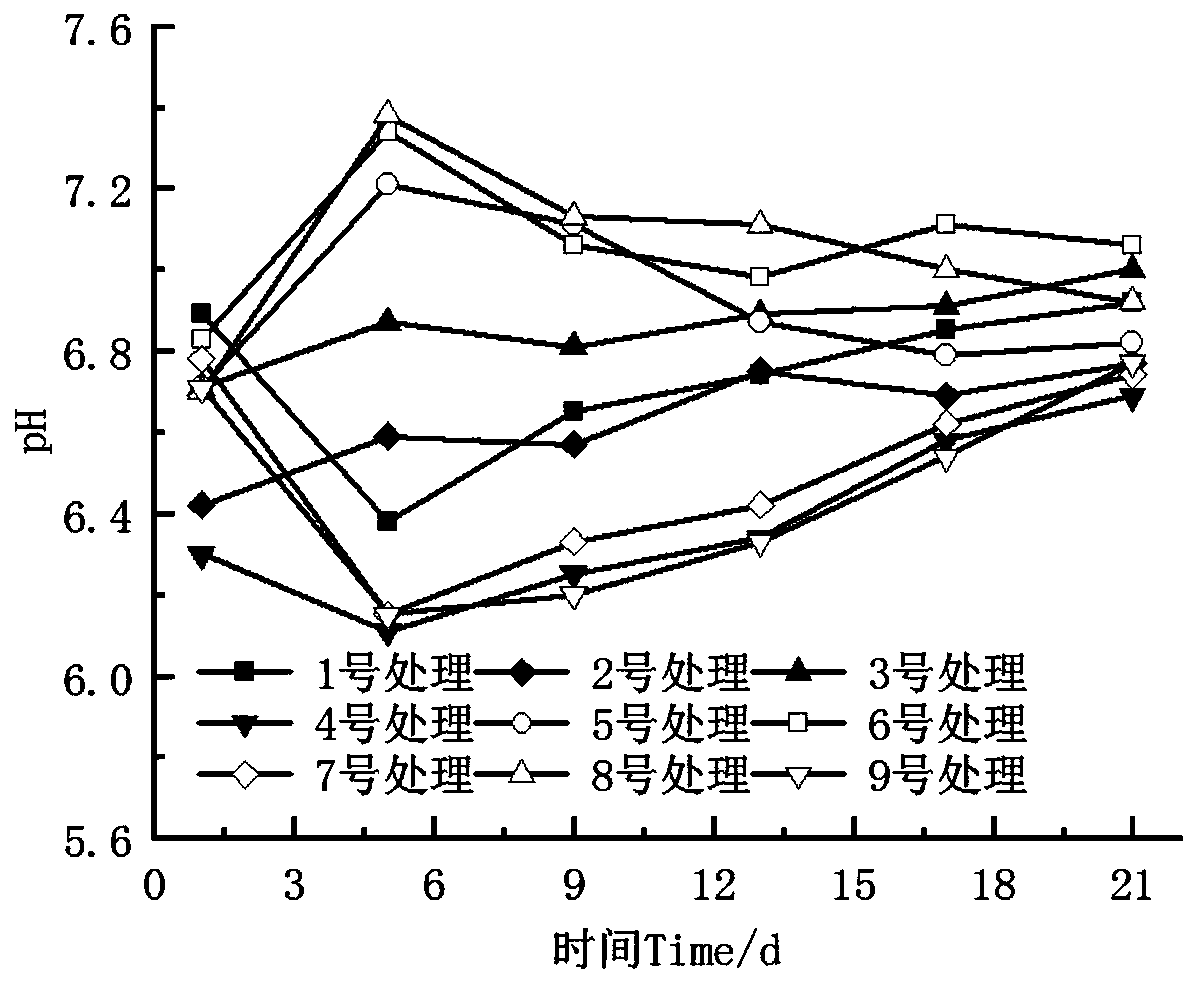

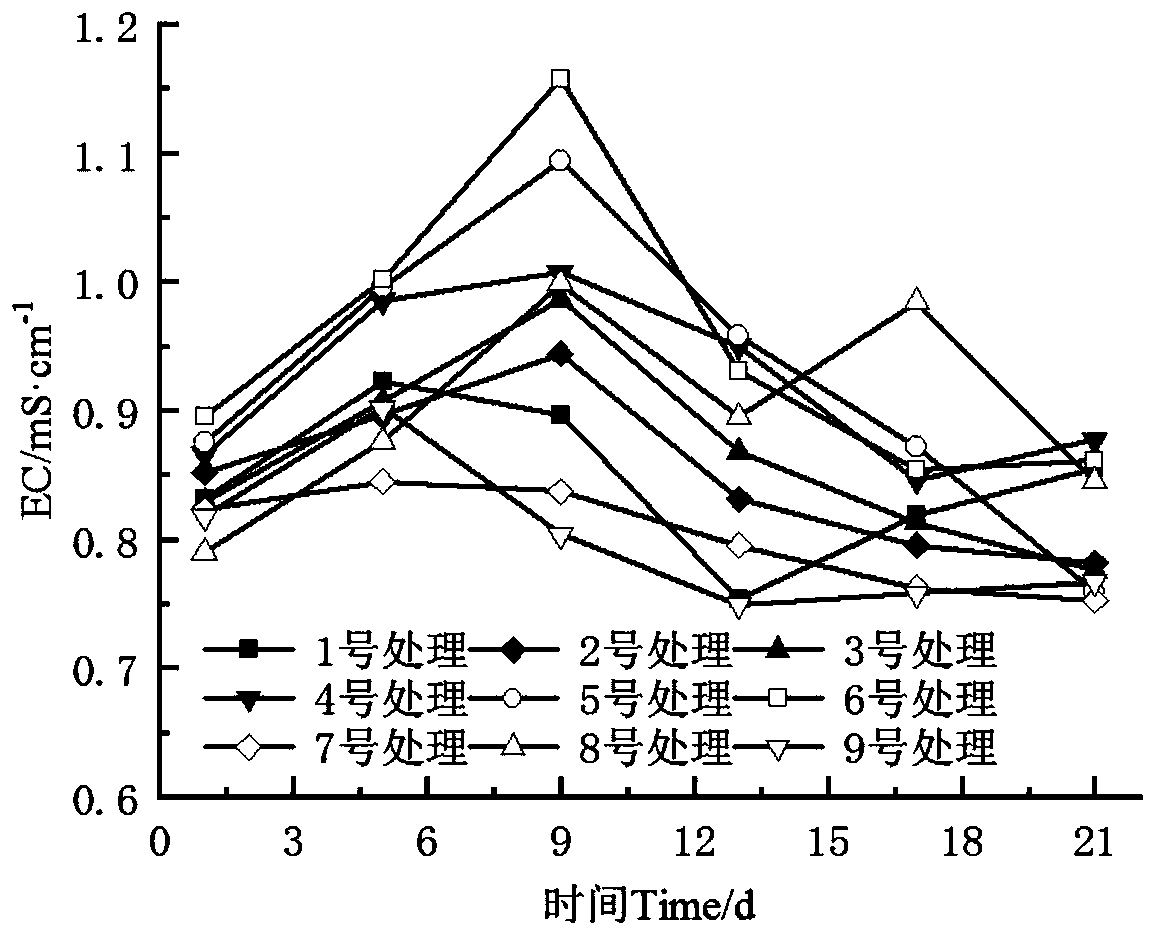

[0077] (2) composting: put the premixed material of step (1) into the adiabatic composting reactor, add the high-temperature aerobic composting bacterial agent composting of 1% of the weight of the premixed material obtained in step (1), and carry out aerobic composting fermentation, The temperature in the center of the heap is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com