Extraction process of total flavonoids of overground part of bupleurum chinense cultivated in Ningxia

An aerial part and extraction process technology, which is applied in the field of extraction process of total flavonoids from aerial parts of cultivated Bupleurum chinensis in Ningxia, can solve the problems of unfavorable industrial production, long extraction time, low extraction rate, etc., and is convenient for large-scale production and easy to propose. , The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

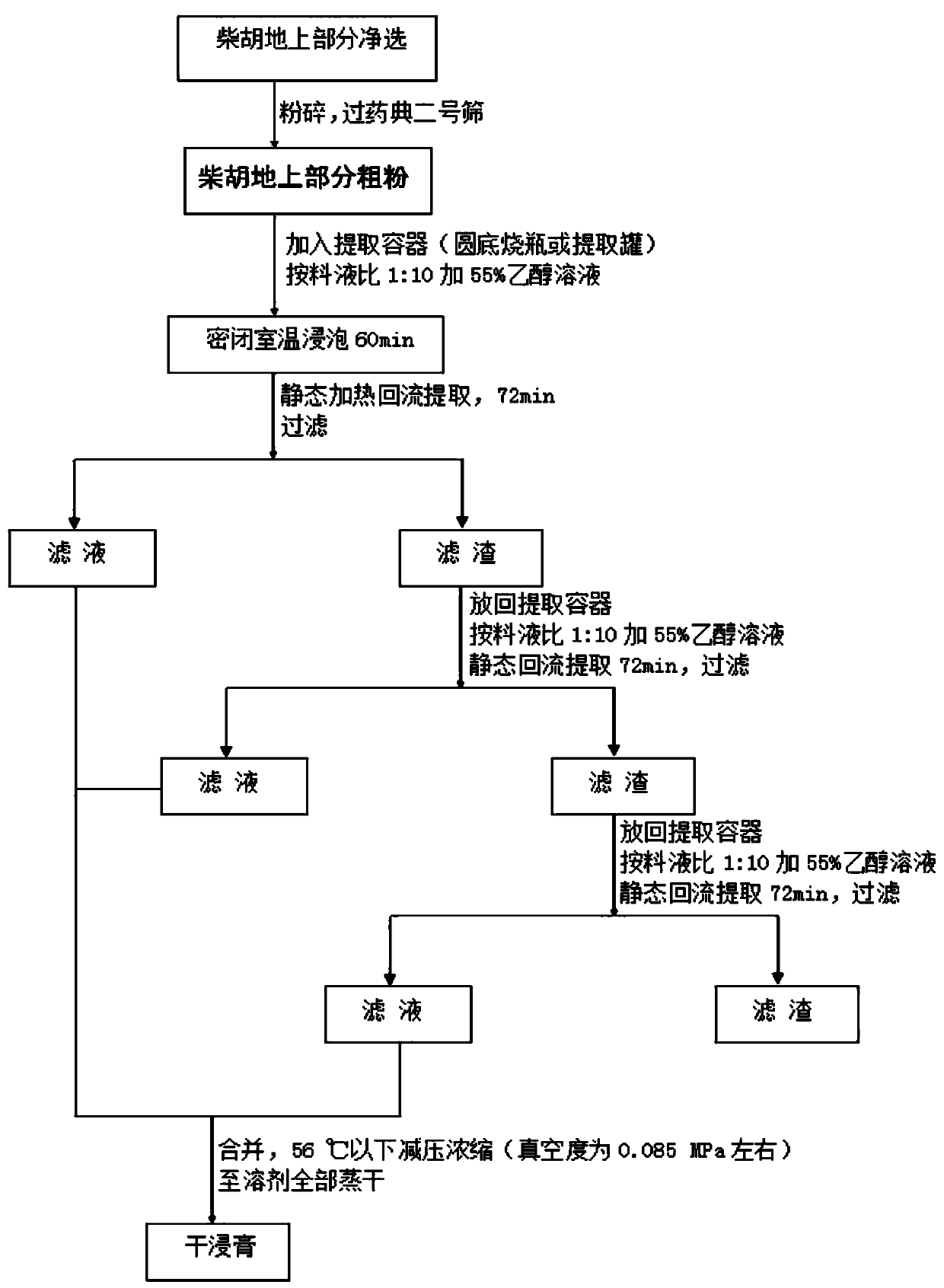

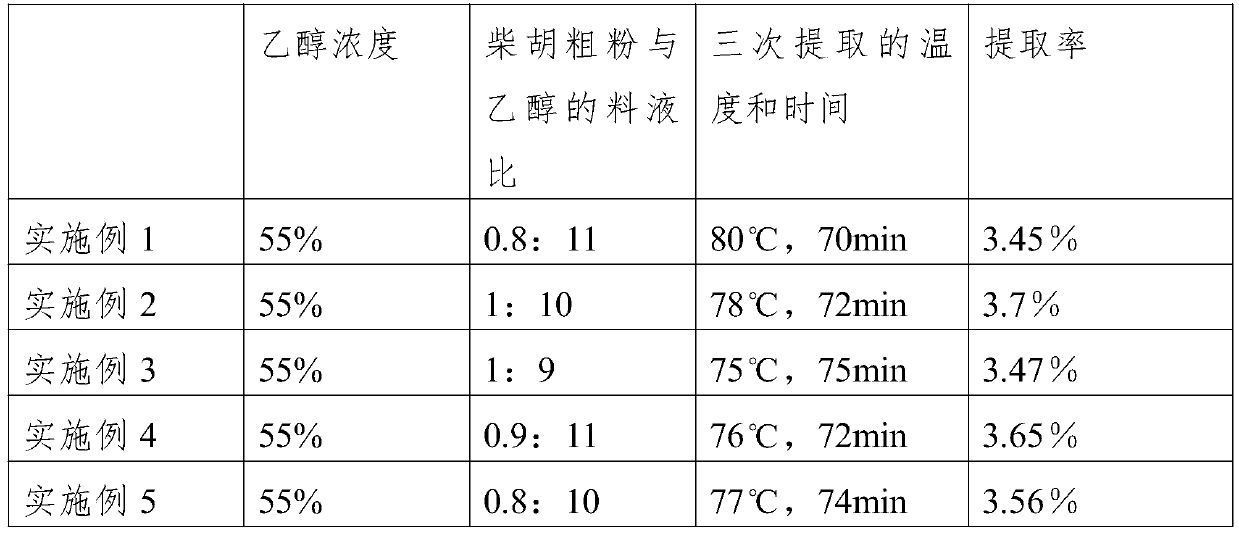

[0029] The extraction process of the total flavonoids of the above-ground part of Bupleurum bupleuri cultivated in Ningxia in this embodiment includes four steps of crushing, soaking at room temperature, static heating and reflux extraction and concentration;

[0030] The extraction process of the total flavonoids of the above-ground part of Bupleurum bupleurum is specifically as follows:

[0031] Step 1, crushing, selecting the aerial part of Bupleurum bupleuri cultivated in Ningxia, drying it naturally, crushing it with a small swinging grinder and passing through No.

[0032] Step 2. Soaking at room temperature: put the coarse powder of Bupleurum above ground into the extraction container, add 55% ethanol, and soak for 50 minutes at room temperature, wherein the ratio of solid to liquid of coarse powder of Bupleurum above ground and 55% ethanol is 0.8:11;

[0033] Step 3, static reflux extraction: after airtight immersion in 55% ethanol at room temperature, use static heati...

Embodiment 2

[0036] Refer to the attached figure 1 , the extraction process of the total flavonoids of the above-ground part of Bupleurum bupleuri cultivated in Ningxia in this embodiment includes four steps of crushing, soaking at room temperature, static heating and reflux extraction and concentration;

[0037] The extraction process of the total flavonoids of the above-ground part of Bupleurum bupleurum is specifically as follows:

[0038] Step 1, crushing: the aerial part of Bupleurum bupleuri cultivated in Ningxia is selected, aired naturally, pulverized with a small swing pulverizer and passed through a No.

[0039] Step 2. Soaking at room temperature: put the coarse powder of Bupleurum above ground into the extraction container, add 55% ethanol, and soak for 60 minutes at room temperature, wherein the ratio of solid to liquid of coarse powder of Bupleurum above ground and 55% ethanol is 1:10;

[0040] Step 3, static reflux extraction: after airtight immersion in 55% ethanol at room...

Embodiment 3

[0043] The extraction process of the total flavonoids of the above-ground part of Bupleurum bupleuri cultivated in Ningxia in this embodiment includes four steps of crushing, soaking at room temperature, static heating and reflux extraction and concentration;

[0044] The extraction process of the total flavonoids of the above-ground part of Bupleurum bupleurum is specifically as follows:

[0045] Step 1, crushing: the aerial part of Bupleurum bupleurum cultivated in Ningxia is selected, dried naturally, pulverized with a small swing pulverizer and passed through a No.

[0046] Step 2. Soaking at room temperature: put the coarse powder of Bupleurum above ground into the extraction container, add 55% ethanol, and soak for 70 minutes at room temperature, wherein the ratio of solid to liquid between the coarse powder of Bupleurum above ground and 55% ethanol is 1:9;

[0047]Step 3, static reflux extraction: after airtight immersion in 55% ethanol at room temperature, use the stat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap