Collection system for flue gas from modified asphalt production

A technology for collecting flue gas and modifying asphalt, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, which can solve the problems of high energy consumption, low processing efficiency, and high processing cost, and reduce the consumption of manpower and material resources , high collection and processing efficiency, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

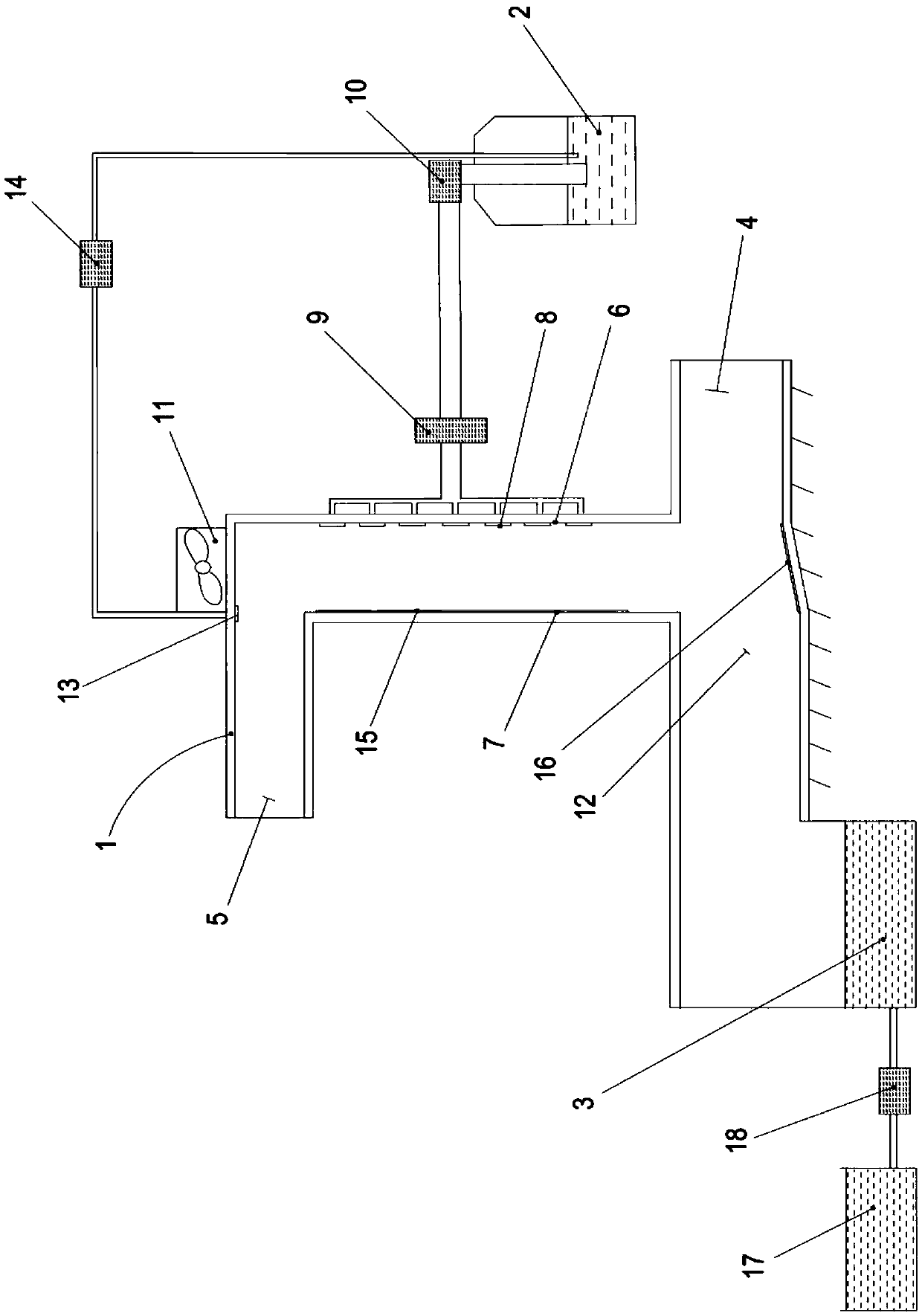

[0014] Such as figure 1 As shown, the modified asphalt smoke collection system includes a chamber 1 for flue gas flow, a water tank 2 for water supply, and a retention pond 3. The chamber 1 is in a zigzag shape, and the zigzag shape does not mean The middle part of the chamber 1 is an inclined straight line, on the contrary, in actual production and construction, the middle part of the chamber 1 is parallel to the vertical direction, so as to facilitate the flow of water and the circulation of smoke. The bottom end of the chamber 1 has a smoke inlet 4, and the top end of the chamber 1 has a smoke exhaust port 5, that is, the smoke flows in from the bottom, and when the smoke flows upward along the middle of the chamber 1, it will be liquefied by mist Flow down the inner wall. Only when cleaning is needed, the remaining little smoke will be discharged from the smoke exhaust port 5, so the smoke exhaust port 5 will not be used as smoke exhaust daily. The middle part of the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com