Preparation method of Ag2O-ZnO/g-C3N4 photocatalytic ozonization catalyst

A g-c3n4, ozonation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as limited applications, and achieve fast speed and reaction The effect of high activity and high mineralization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This application provides an Ag 2 O-ZnO / g-C 3 N 4 The preparation method of photocatalytic ozonation catalyst comprises the steps:

[0030] S1, providing a first solution, the first solution comprising Ag 2 O, ZnO, g-C 3 N 4 and dispersants, the Ag 2 O, ZnO and g-C 3 N 4 Uniformly dispersed in the first solution; the preparation of the first solution includes: g-C 3 N 4 Put the powder in 200ml dispersant, set the temperature of the ultrasonic cleaner to 20°C, ultrasonically disperse for 60min, then add AgNO 3 , after stirring at a high speed of 10000r / min for 60min, adjust the pH to 10 with 5M NaOH to obtain the first reactant, add nano-ZnO powder to the first reactant, and stir for 30min at a speed of 1000r / min , to obtain the first solution. The molar ratio of Ag+ to Zn2+ in the first solution is 1:20. Ag in the first solution 2 O-ZnO and g-C 3 N 4 The mass ratio is 1:8. The temperature of the stirring reflux is 76°C. The time of the stirring and refl...

Embodiment 2

[0036] This application provides an Ag 2 O-ZnO / g-C 3 N 4 The preparation method of photocatalytic ozonation catalyst comprises the steps:

[0037] S1, providing a first solution, the first solution comprising Ag 2 O, ZnO, g-C 3 N 4 and dispersants, the Ag 2 O, ZnO and g-C 3 N 4 Uniformly dispersed in the first solution; the preparation of the first solution includes: g-C 3 N 4 Put the powder in 200ml dispersant, set the temperature of the ultrasonic cleaner to 26°C, ultrasonically disperse for 36min, then add Ag 2 SO 4 After stirring at a high speed of 1006r / min for 46min, adjust the pH to 11 with 6M NaOH to obtain the first reactant, add nano-ZnO to the first reactant, and stir for 33min at a speed of 1003r / min, A first solution is obtained. The molar ratio of Ag+ to Zn2+ in the first solution is 1:19. Ag in the first solution 2 O-ZnO and g-C 3 N 4 The mass ratio is 1:7. The dispersant is selected from water. The temperature of the stirred reflux is 96°C. T...

Embodiment 3

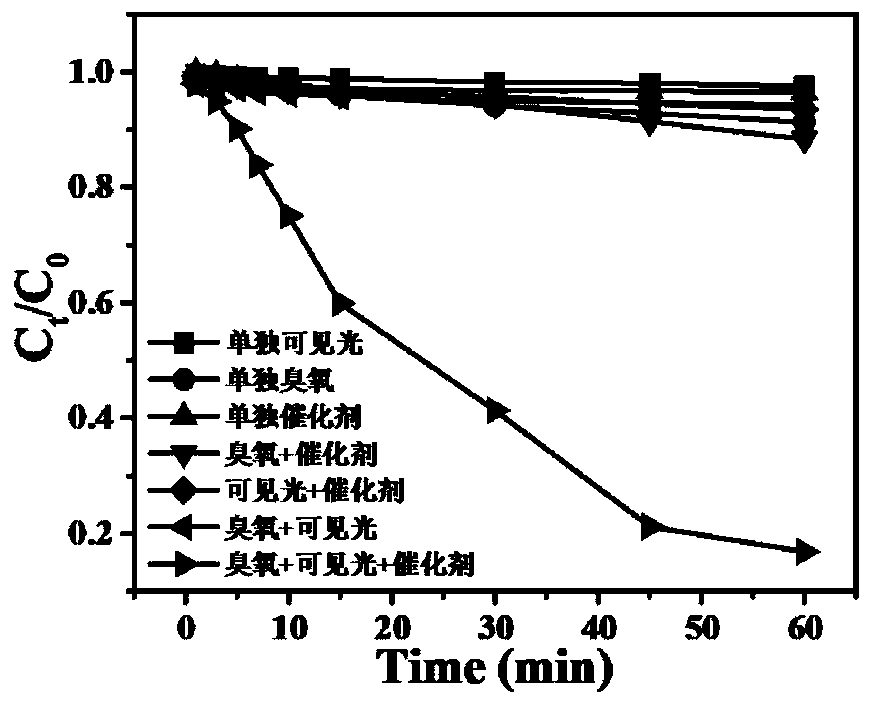

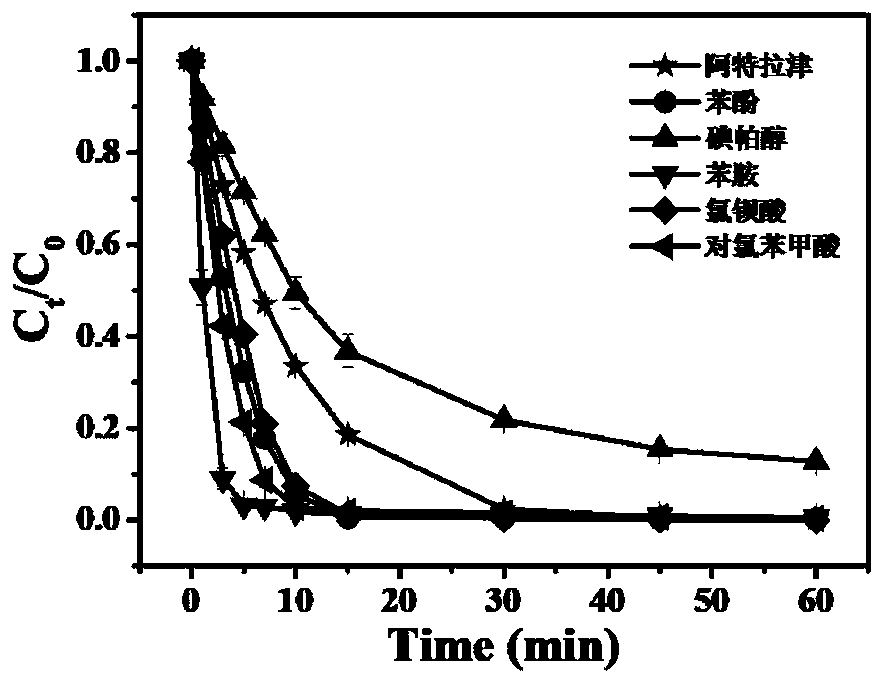

[0042] see Figure 1-2 , the application provides an Ag 2 O-ZnO / g-C 3 N 4 The preparation method of photocatalytic ozonation catalyst comprises the steps:

[0043] S1, providing a first solution, the first solution comprising Ag 2 O, ZnO, g-C 3 N 4 and dispersants, the Ag 2 O, ZnO and g-C 3 N 4 Uniformly dispersed in the first solution; the preparation of the first solution includes: g-C 3 N 4 Put the powder in 200ml dispersant, set the temperature of the ultrasonic cleaner to 35°C, ultrasonically disperse for 30min, then add Ag 2 SO 4 After stirring at a high speed of 1200r / min for 45min, adjust the pH to 12 with 8M NaOH to obtain the first reactant, add nano-ZnO to the first reactant, and stir for 30min at a speed of 1200r / min, A first solution is obtained. The molar ratio of Ag+ to Zn2+ in the first solution is 1:20. Ag in the first solution 2 O-ZnO and g-C 3 N 4 The mass ratio is 1:4. The dispersant is selected ethanol. The temperature of the stirring re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com