Steel pipe cutting device for bridge construction

A technology for cutting devices and steel pipes, which is applied in the direction of pipe shearing devices, shearing devices, positioning devices, etc., can solve the problems of inability to quickly cool down steel pipes, poor cutting and positioning stability, etc., to improve the cooling effect, improve applicability, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

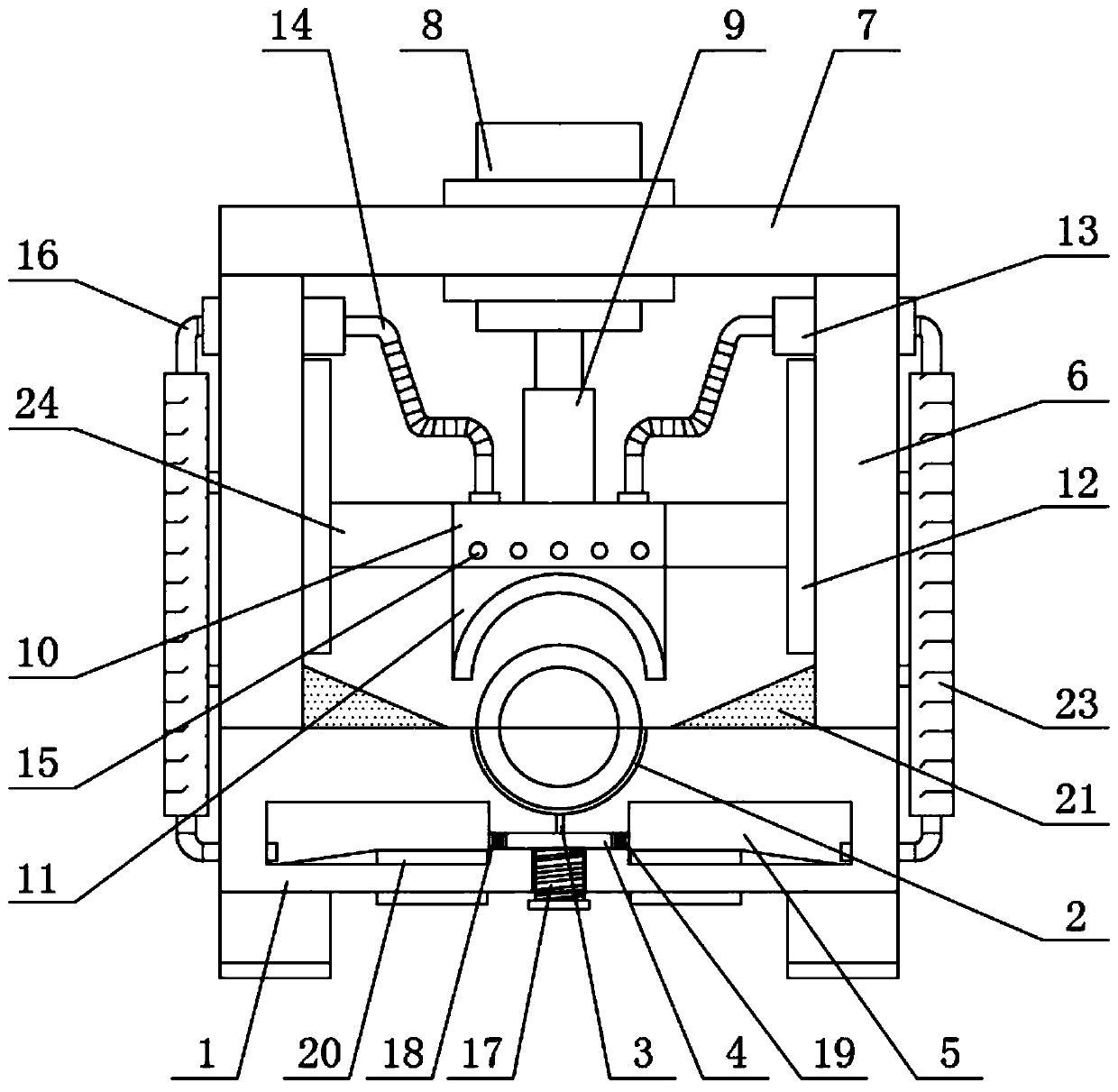

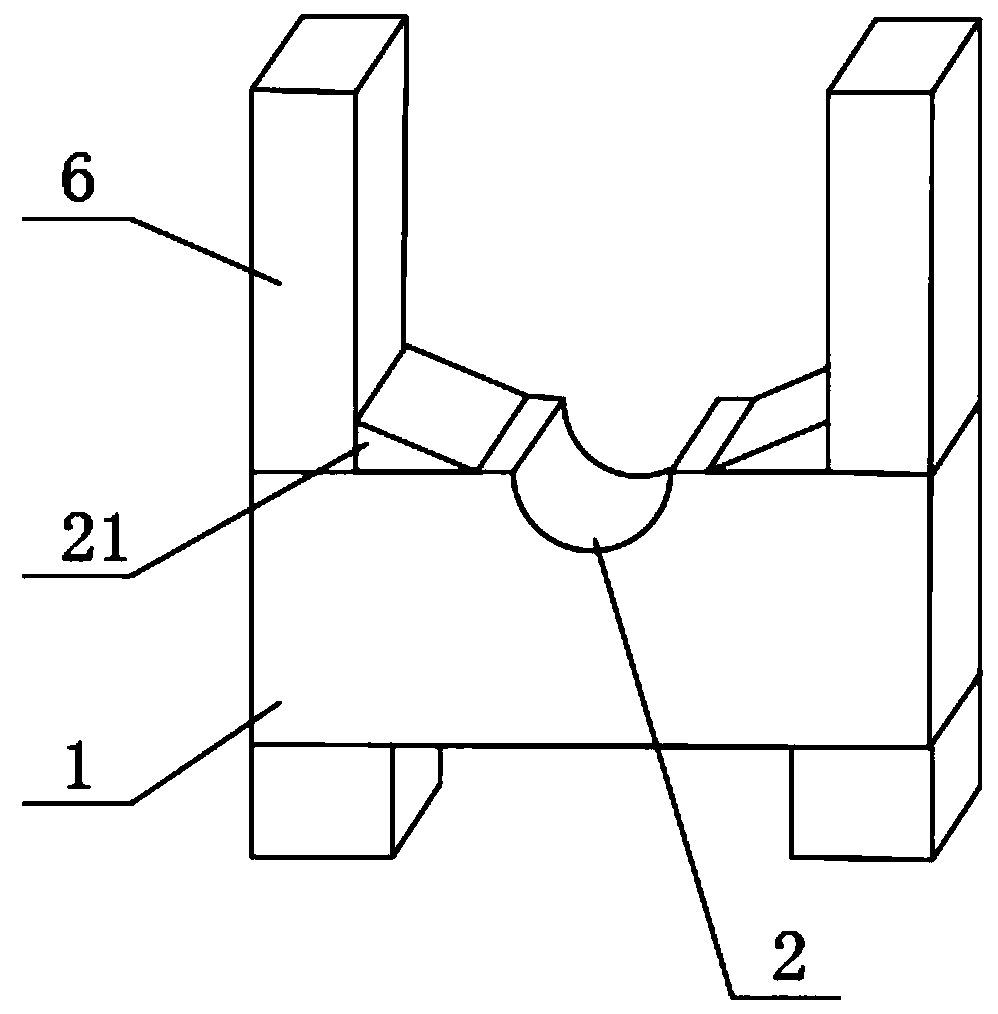

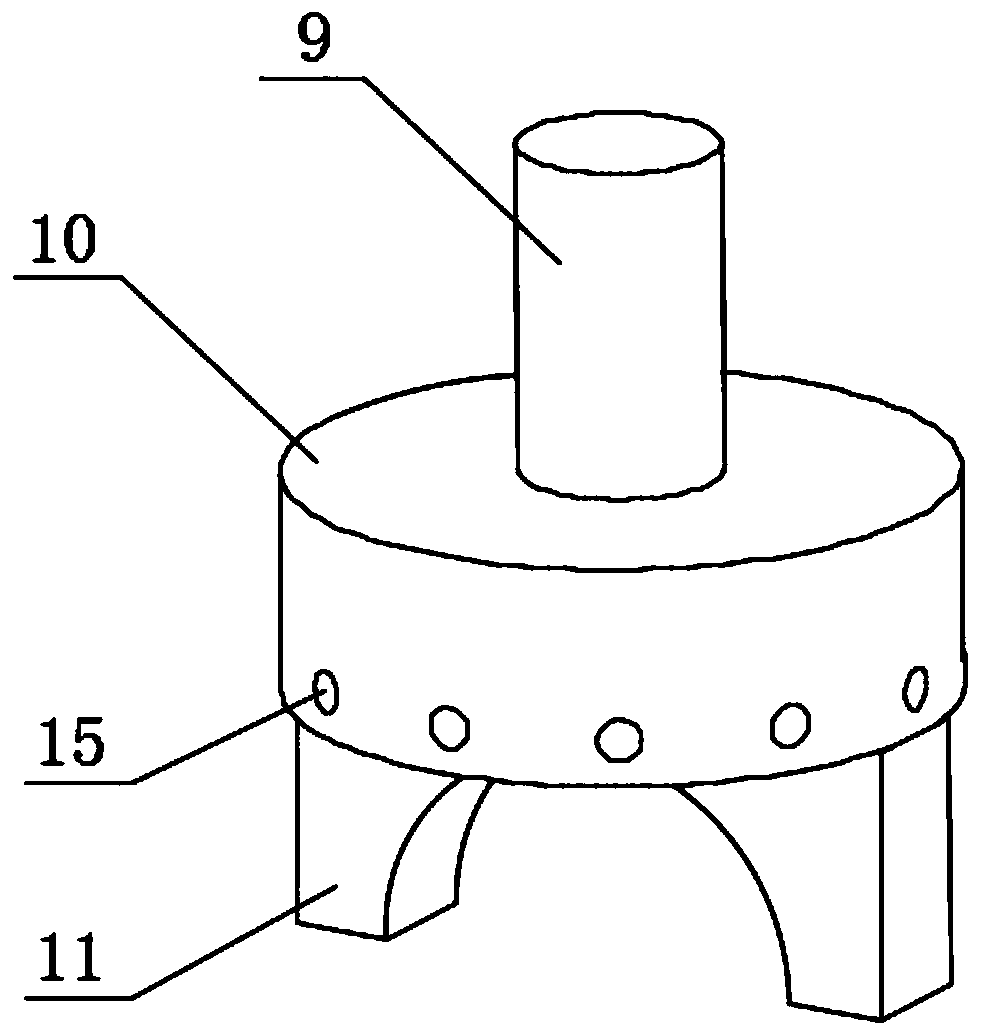

[0023] Such as Figure 1-4 As shown, the present invention provides a technical solution: a steel pipe cutting device for bridge construction, including a fixed seat 1, the upper surface of the fixed seat 1 is fixedly connected with two symmetrical inclined blocks 21, and the outer surface of the inclined block 21 is connected to the The outer surfaces of the first support plate 6 are in contact with each other. By setting the inclined block 21, the side leakage of the water flow when the cooling box 10 is sprayed can be avoided, the waste of water resources is reduced, and the cooling effect on the steel pipe surface is improved. There is a cutting groove 2, and the bottom surface of the cutting groove 2 is provided with a water leakage hole 3, and the bottom of the water leakage hole 3 is fixedly connected with a shunt hole 4, and the inner bottom wall of the shunt hole 4 is fixedly connected with a decompression plate 18, and the inside of the decompression plate 18 There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com