Kinematic calibration method of industrial robot

A robot kinematics and calibration method technology, which is applied in the field of industrial robot kinematics calibration, can solve problems such as inability to obtain accurate kinematics models and industrial robot kinematics parameter errors, and achieve low model accuracy, strong practicability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

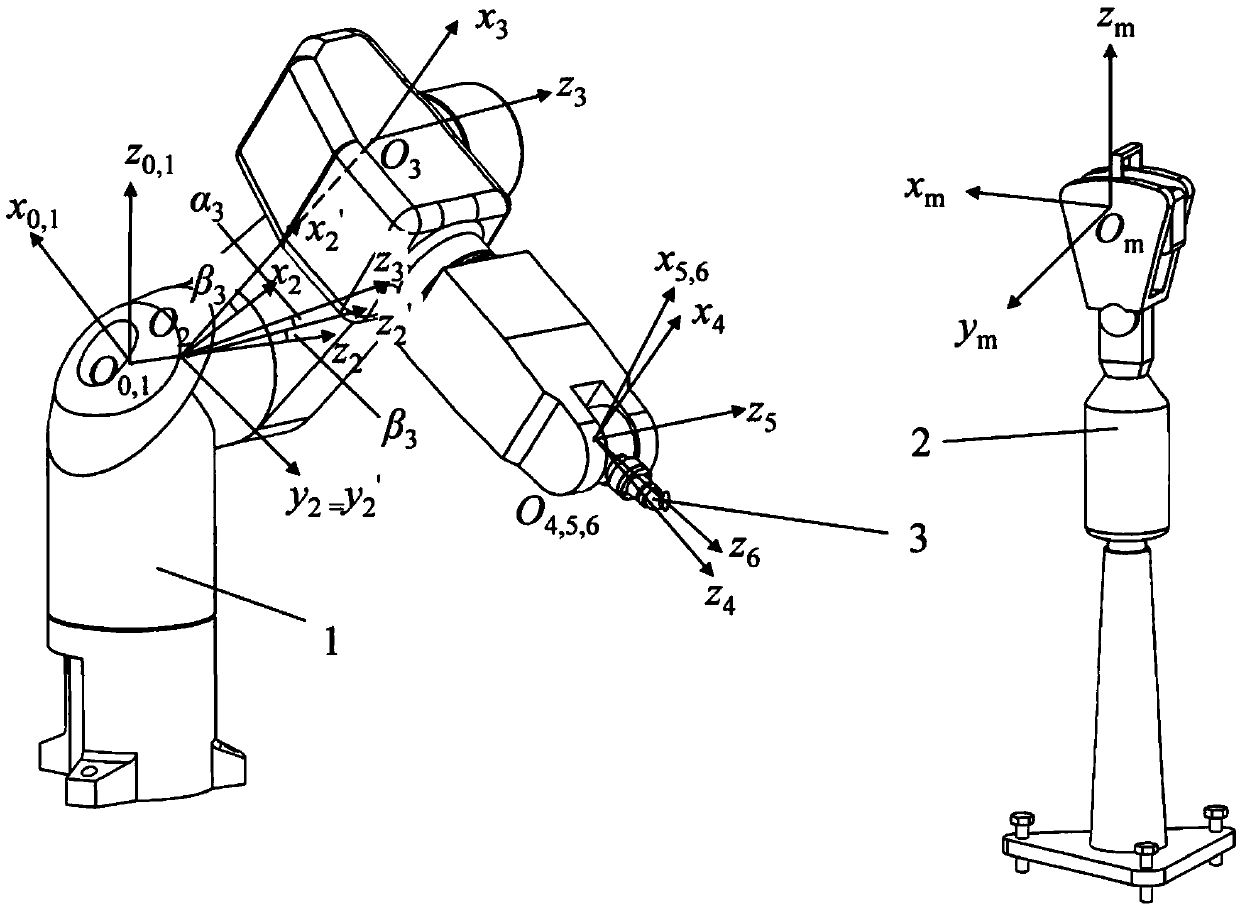

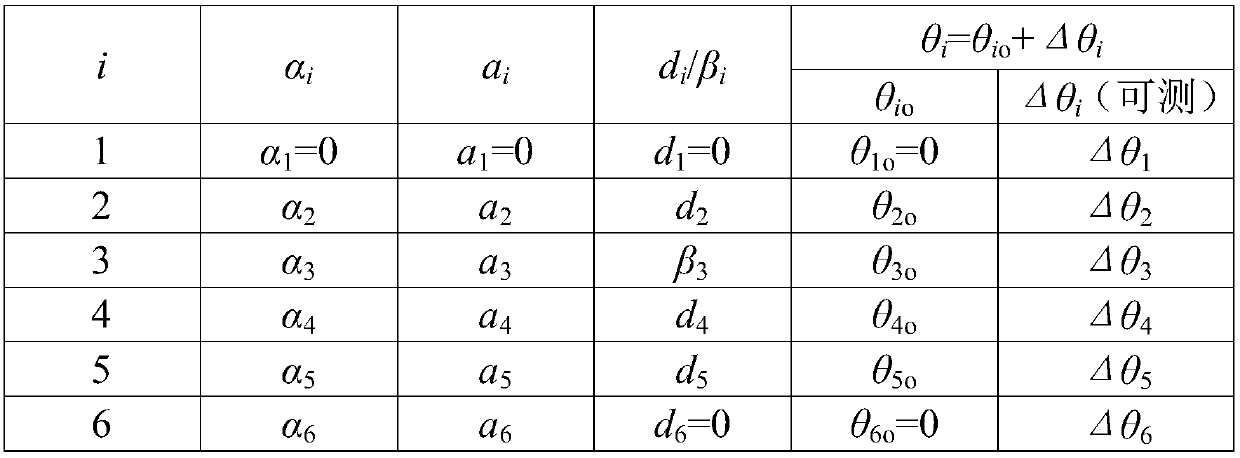

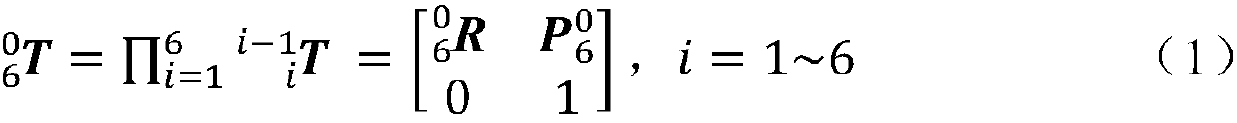

[0030] The industrial robot calibration method of the present invention includes four parts: establishing an industrial robot kinematics model, establishing a measurement process model, establishing a calibration system model, and solving nonlinear calibration models to identify kinematic parameters. In the process of establishing the industrial robot kinematics model, the DH and MDH rules are combined to establish the coordinate system of the intermediate link, and the minimum parameter set to be identified including 18 parameters is obtained. When the nominal value of the angle between the axes of two adjacent joints is 90 degrees, the DH rule is used; when the nominal value of the angle between the axes of two adjacent joints is 0 degrees, the MDH rule is used. The coordinate system of the first link coincides with the coordinate system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com