A kind of microbe maintenance method without water for baf

A technology of microorganisms and biological aerated filters, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of huge environmental pollution damage and failure to meet normal standards, so as to avoid inhibition and maintain The effect of normal growth metabolism and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

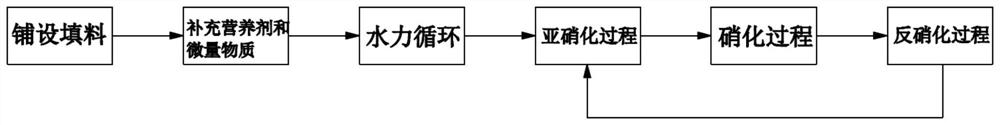

Method used

Image

Examples

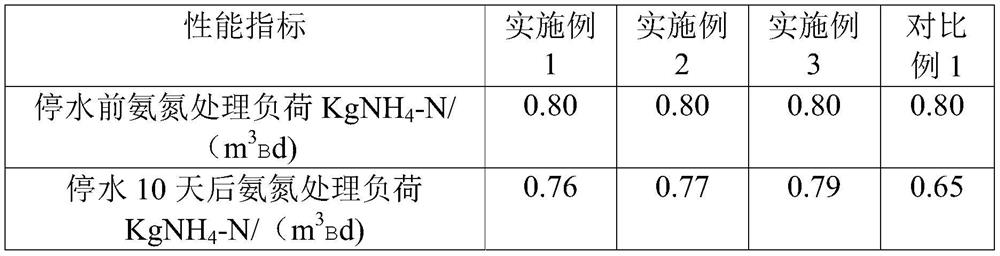

Embodiment 1

[0041] A kind of BAF water cut off microbial maintenance method, comprises the following steps:

[0042] 1) Filling: The microorganisms of the biological aerated filter are upward-flowing biological aerated filters, and the bottom is connected with the water inlet and the upper part of the inlet water distribution pipe, and pebbles with a height of 0.2 meters and a particle size of 15-20mm are laid as a supporting layer ; The upper part of the supporting layer is filled with 4.5 meters of activated zeolite as a packing layer for nitrifying bacteria. A clear water area is provided between the packing layer and the upper water outlet of the biological aerated filter, and the height of the clear water area is 0.5m. Among them, the particle size of the activated zeolite is 3-5mm, the porosity is 65%, and the specific surface area is 120m 2 / g; SiO 2 / Al 2 o 3 The molar ratio is less than 4.5, and the cation exchange capacity is 250mmol / g.

[0043] 2) supplement nutrients and ...

Embodiment 2

[0049] A kind of BAF water cut off microbial maintenance method, comprises the following steps:

[0050] 1) Filling: The microorganisms of the biological aerated filter are upward-flowing biological aerated filters, and the bottom is connected with the water inlet and the upper part of the inlet water distribution pipe, and pebbles with a height of 0.2 meters and a particle size of 15-20mm are laid as a supporting layer ; The upper part of the supporting layer is filled with 5.0 meters of activated zeolite as a packing layer for nitrifying bacteria. A clear water area is provided between the packing layer and the upper water outlet of the biological aerated filter, and the height of the clear water area is 1m. Among them, the particle size of the activated zeolite is 3-5mm, the porosity is 75%, and the specific surface area is 160m 2 / g; SiO 2 / Al 2 o 3 It is 4.2, and the cation exchange capacity is 300mmol / g.

[0051] 2) supplement nutrients and trace elements: add nutri...

Embodiment 3

[0057] A kind of BAF water cut off microbial maintenance method, comprises the following steps:

[0058] 1) Filling: The microorganisms in the biological aerated filter are upward-flowing biological aerated filters, and pebbles with a height of 0.2 meters and a particle size of 15-20 mm are laid on the bottom of the water inlet and the inlet water distribution pipe as a supporting layer ; The upper part of the supporting layer is filled with 4.5 meters of activated zeolite as a packing layer for nitrifying bacteria. A clear water area is provided between the packing layer and the upper water outlet of the biological aerated filter, and the height of the clear water area is 0.6m. Among them, the particle size of the activated zeolite is 3-5mm, the porosity is 75%, and the specific surface area is 200m 2 / g; SiO 2 / Al 2 o 3 is 4.0, and the cation exchange capacity is 400 mmol / g.

[0059] 2) supplement nutrients and trace elements: in the clear water area of the biological...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com