Electroplating wastewater treatment method

A technology of electroplating wastewater and treatment methods, which is applied in metallurgical wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of large area occupied by electroplating leaching wastewater, long settling time, and large amount of waste residue, etc., to achieve Reduce the amount of wastewater, improve treatment efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking pyrophosphate copper plating leaching wastewater discharged from an electroplating factory as the treatment object, the main pollutant concentrations in the wastewater are: copper 50mg / L, total phosphorus 200mg / L.

[0021] A treatment method for electroplating wastewater, comprising the steps of:

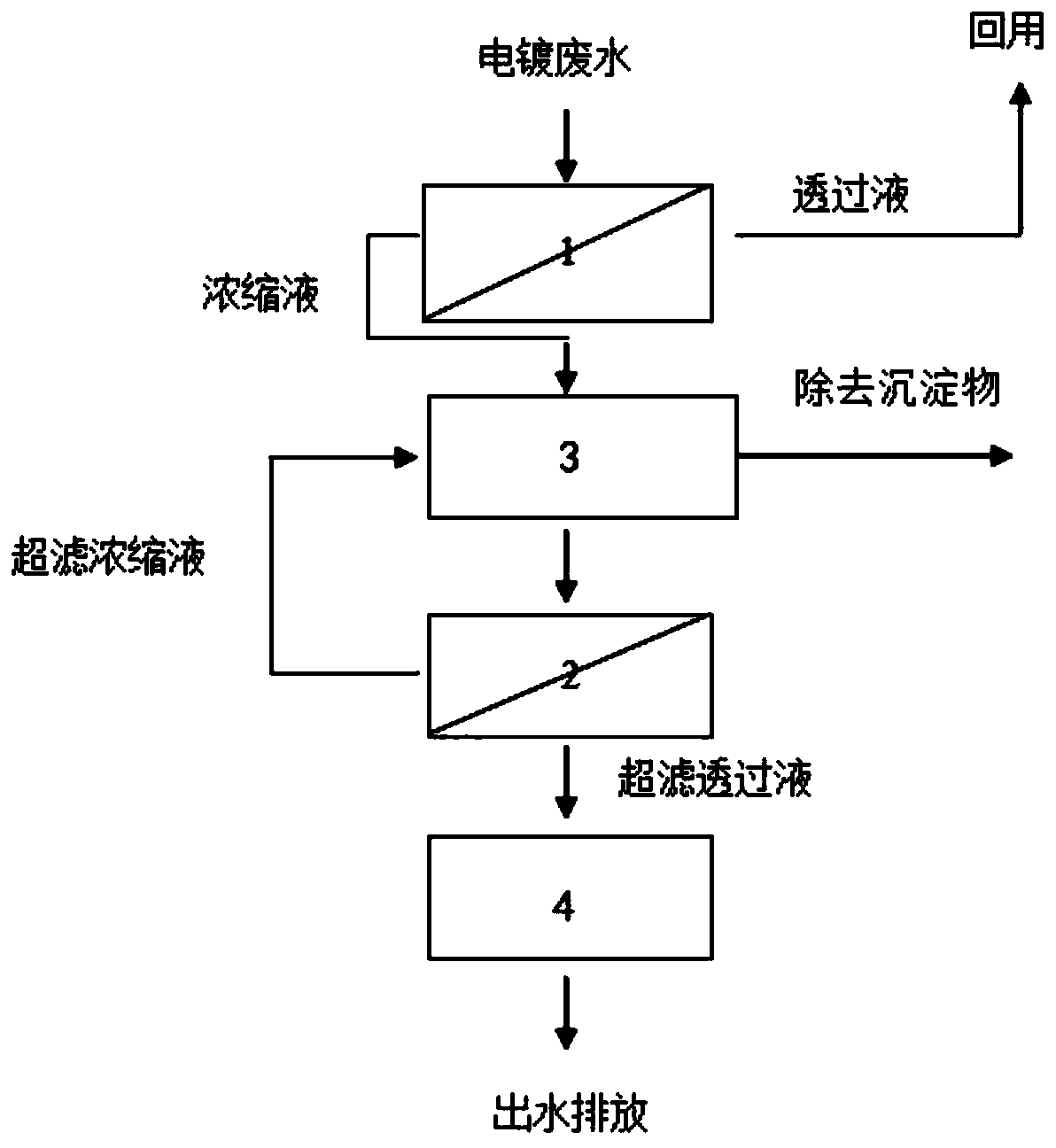

[0022] 1) Pass the collected electroplating wastewater (leaching wastewater) into the nanofiltration membrane module 1 for treatment, and after concentrating 10 times, obtain the permeate and concentrated solution, and reuse the permeate as the rinsing water in the electroplating process, concentrate The liquid passes into the chemical sedimentation tank 3;

[0023] Concentration of main pollutants in concentrated solution: copper 500mg / L, total phosphorus 2000mg / L;

[0024] 2) Add the chemical precipitant calcium hydroxide to the chemical precipitation tank 3, and stir at 150r / min for 20 minutes to precipitate the heavy metal ions in the electroplating wastewater; (r...

Embodiment 2

[0029] Taking the nickel plating wastewater discharged from an electroplating factory as the treatment object, the concentration of the main pollutants in the wastewater is: nickel 60mg / L.

[0030] A treatment method for electroplating wastewater, comprising the steps of:

[0031] 1) The electroplating waste water is passed into the reverse osmosis membrane module 1 for treatment, and after being concentrated 10 times, the permeate and the concentrate are obtained, and the permeate is reused as rinsing water in the electroplating process, and the concentrate flows into the chemical precipitation tank 3; The main pollutant concentration of electroplating wastewater after concentration is: nickel 600mg / L;

[0032] 2) Add the chemical precipitant sodium hydroxide to the chemical precipitation tank 3 to make pH=11, stir at 100r / min for 18min, and precipitate the heavy metal ions in the electroplating wastewater; remove);

[0033] 3) The liquid obtained in step 2) is passed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com