Heavy-metal-containing electroplating wastewater treatment and heavy metal recycling method

A technology for electroplating wastewater and heavy metals, which is used in metallurgical wastewater treatment, reduced water/sewage treatment, water/sewage multi-stage treatment, etc. problems such as low concentration, to achieve the effect of reducing the volume of process wastewater, reducing the volume of wastewater, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

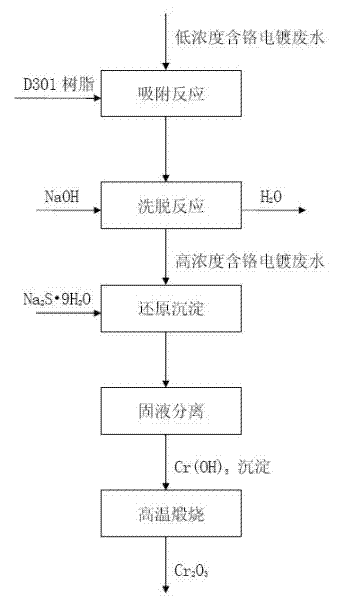

[0052] The heavy metal-containing electroplating wastewater treatment and heavy metal recycling method of the present invention comprises the following steps:

[0053] 1. Ion exchange enrichment: The low concentration electroplating wastewater containing heavy metal ions such as chromium, nickel, cadmium, copper, etc. is enriched into high concentration electroplating wastewater through ion exchange reaction with ion exchange resin. Specifically include:

[0054] 1) Adsorption reaction: The heavy metal substances contained in the electroplating wastewater are completely adsorbed on the ion exchange resin and clean water is separated until the adsorption of the ion exchange resin reaches saturation;

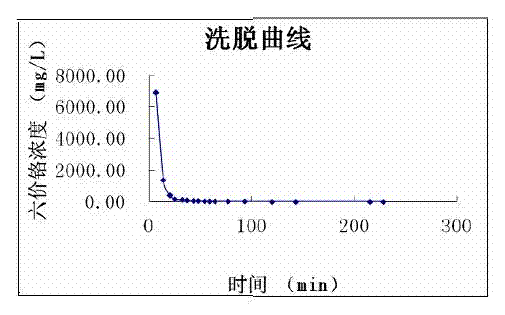

[0055] 2) Elution reaction: adding an eluent to separate the heavy metal substances adsorbed on the ion exchange resin from the ion exchange resin to produce high-concentration electroplating wastewater. The eluent is a strong alkaline solution such as NaOH solution. When treatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com