System and method for purifying and reutilizing surface runoff water resources

A surface runoff and water resources technology, applied in the field of surface runoff water resource purification and reuse, can solve the problems of poor pollutant removal effect, weak surface runoff pollution control effect, secondary pollution, etc., to avoid secondary pollution of water bodies, Improved operating efficiency, service life, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

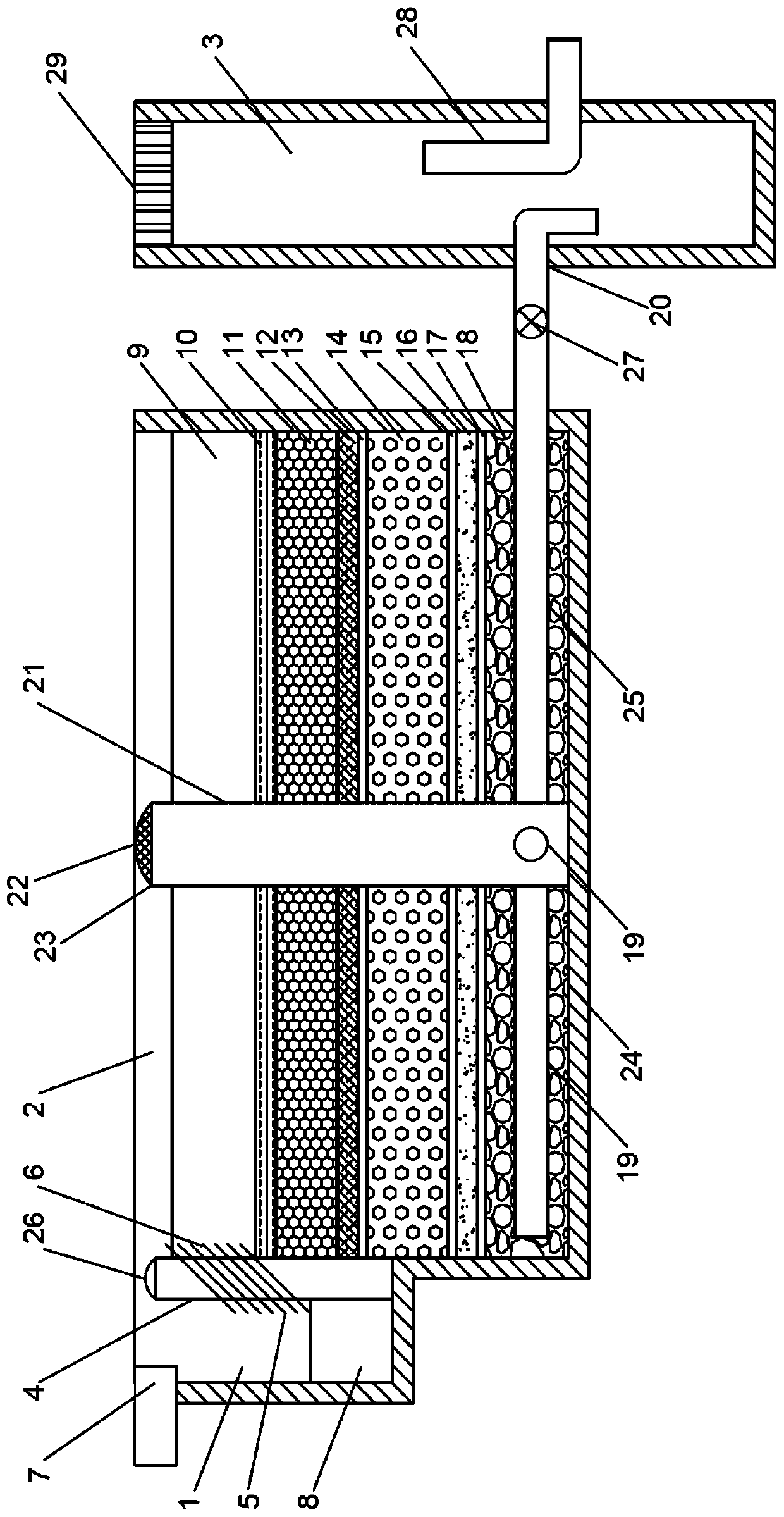

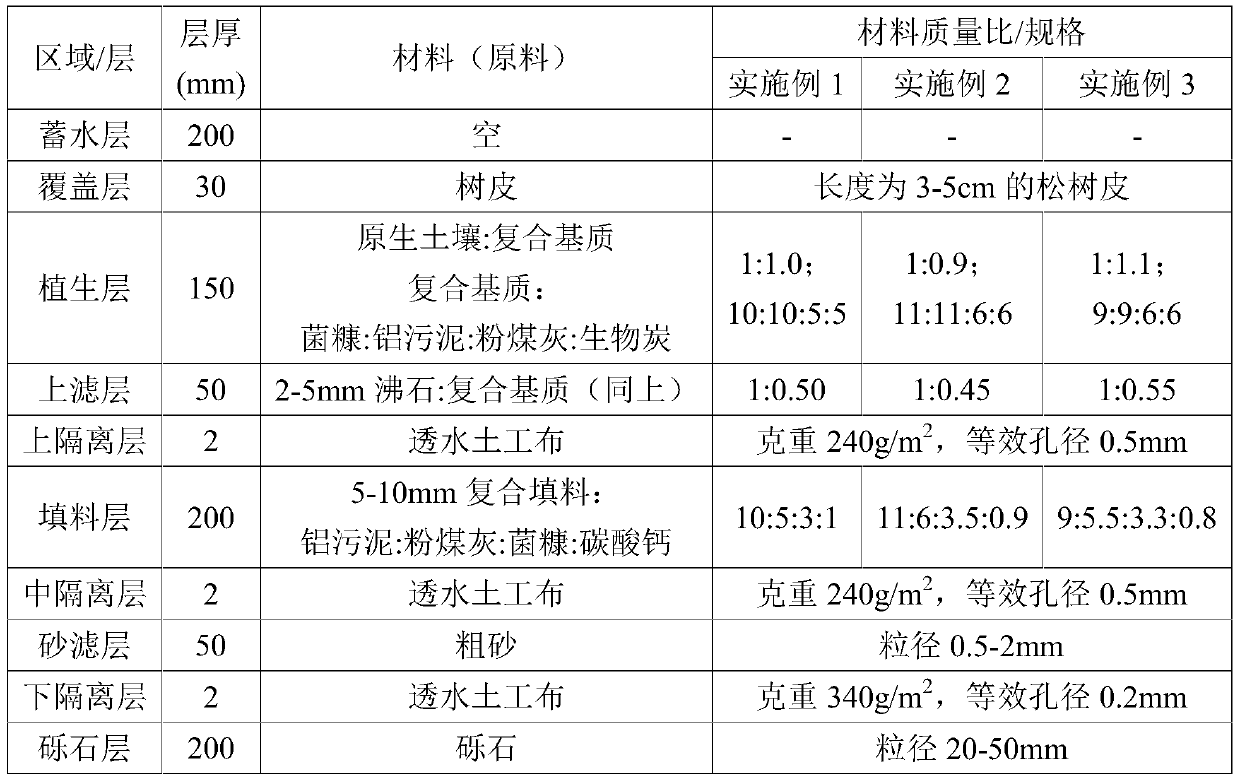

[0041] The system for purification and reuse of surface runoff water resources of this embodiment, such as figure 1 As shown, it includes a front water collection tank 1, a biological retention tank 2 and a rear water collection well 3. A rectification wall 4 is provided between the front water collection tank 1 and the biological retention tank 2, and the rectification wall 4 is embedded with Multi-layer parallel inclined plates 5 with an angle of 45° inclined upward from the front water collection tank 1 to the biological retention tank 2 (in the direction of normal water flow) (the total thickness of the multi-layer parallel inclined plates is 200-500mm, here is 200mm; The vertical height of the layer channel is 20-100mm, here preferably 30mm), the parallel channel 6 between the multi-layer parallel inclined plates 5 connects the front water collection tank 1 and the biological retention tank 2; the top of the rectifying wall 4 is an overflow Flow weir 26;

[0042] The front w...

Embodiment 2

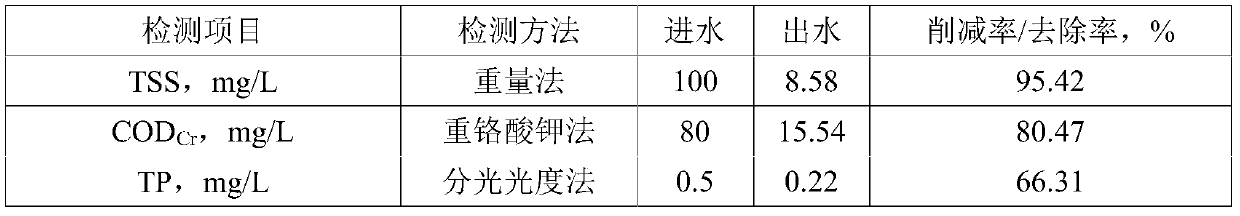

[0056] The specific structure of the system for purifying and reusing surface runoff water resources of this embodiment is the same as that of Embodiment 1, and the materials used in each layer of the biological retention tank are shown in Table 1.

[0057] In this embodiment, the method for purifying and reusing surface runoff water resources of the aforementioned system includes the following steps:

[0058] 1) Take the formula amount of bacterial chaff, aluminum sludge, fly ash, and biochar to mix evenly, adjust the pH to 6.0-7.3 with ferrous sulfate to obtain a mixed matrix; mix the obtained mixed matrix with the native soil according to the designed ratio, Obtain vegetation layer material; mix the obtained mixed matrix and zeolite according to the designed ratio to obtain the filter layer material;

[0059] Take the formula amount of fly ash, mushroom chaff, and calcium carbonate and mix it evenly, then add aluminum sludge slurry (made by adding water to aluminum sludge, the amo...

Embodiment 3

[0064] The specific structure of the system for purifying and reusing surface runoff water resources of this embodiment is the same as that of Embodiment 1, and the materials used in each layer of the biological retention tank are shown in Table 1.

[0065] In this embodiment, the method for purifying and reusing surface runoff water resources of the aforementioned system includes the following steps:

[0066] 1) Take the formula amount of bacterial chaff, aluminum sludge, fly ash, and biochar to mix evenly, adjust the pH to 6.0-7.3 with ferrous sulfate to obtain a mixed matrix; mix the obtained mixed matrix with the native soil according to the designed ratio, Obtain vegetation layer material; mix the obtained mixed matrix and zeolite according to the designed ratio to obtain the filter layer material;

[0067] Take the formula amount of fly ash, mushroom chaff, and calcium carbonate and mix it evenly, then add aluminum sludge slurry (made by adding water to aluminum sludge, the amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap