Cement-based repair mortar composition and preparation method thereof

A cement-based, composite technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as deterioration, easy generation of looseness, spalling, accelerated durability of concrete, etc. The effect of strong impact deformation resistance, enhanced bond strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

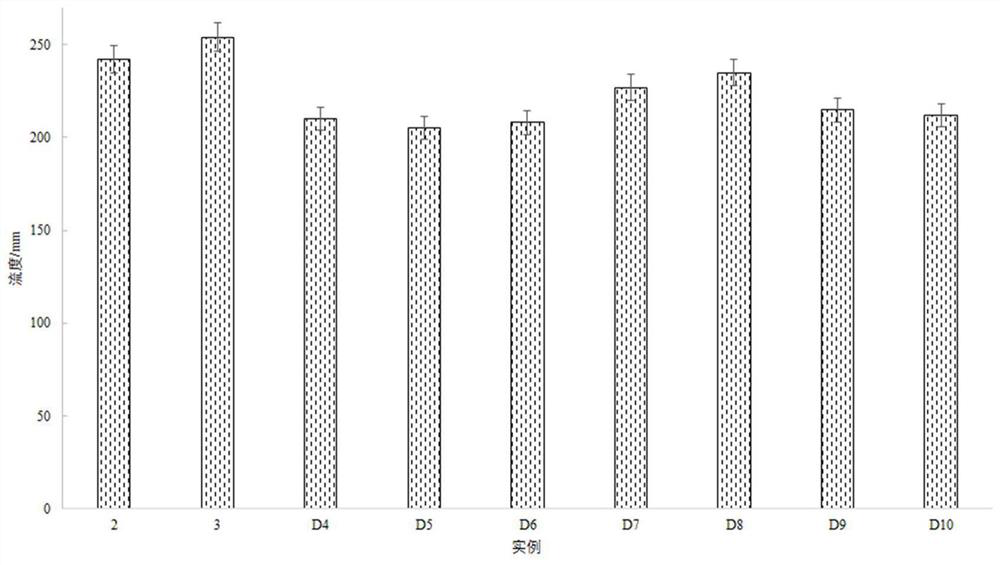

Examples

Embodiment 1

[0067] Example 1: A cement-based repair mortar enhancer formula:

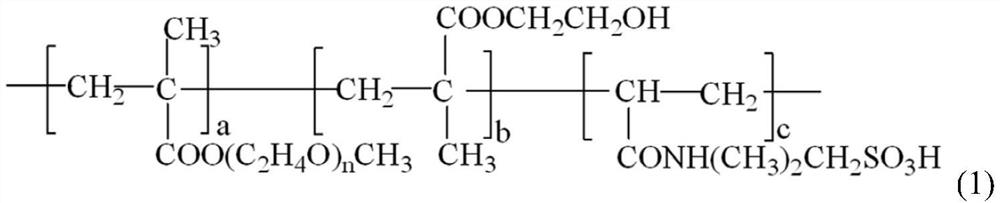

[0068] This embodiment provides a cement-based repair mortar reinforcing agent formulation, wherein the reinforcing agent includes modified plant fibers, water-based epoxy resin and ester-based polycarboxylic acid-based water reducing agent in a weight ratio of 1:0.4:0.6.

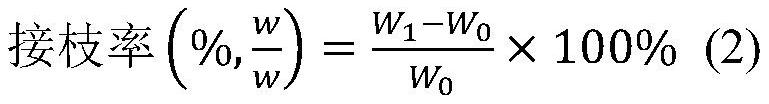

[0069] Wherein, the modified plant fiber is carboxy mulberry fiber grafted silk fibroin with a graft ratio of ≥25%, and the preparation method includes:

[0070] 1) Preparation of ionic liquid: Accurately weigh triethyl phosphate and 1-ethylimidazole according to the weight ratio of 2.2:1, heat and stir the reaction under the conditions of 80°C for 3h, 120°C for 2h, and 130°C for 6h under nitrogen protection, and the reaction ends. After cooling to room temperature, washing with ethyl acetate, rotary evaporation at 50 °C for 2.5 h, and vacuum drying at 65 °C for 12 h;

[0071]2) Pretreatment of mulberry fiber: under the aid of 22.5kHz, 16...

Embodiment 2

[0083] Example 2: A cement-based repair mortar composition formula:

[0084] A cement-based repair mortar composition, the composition contains

[0085] 125 parts by weight of cement;

[0086] 100 parts by weight of fine aggregate;

[0087] 15.0 parts by weight of cement-based repair mortar reinforcing agent described in Example 1;

[0088] Nano-SiO 2 2.0 parts by weight;

[0089] 50 parts by weight of water;

[0090] Wherein, the cement includes 50.0wt% of 42.5 Portland cement, 37.5wt% of fast-hardening sulfoaluminate cement and 12.5wt% of fly ash, and the fly ash is Class II fly ash, which is burnt Loss≤8%, fineness≤20%, activity index 28d≥70%;

[0091] Wherein, the fine aggregate is a mixture of 40 mesh river sand and 80 mesh sea sand.

[0092] The method for preparing the cement-based repair mortar composition described in this embodiment includes:

[0093] 1) form a hydraulic composition, which includes the cement, fine aggregate and nano-SiO described in this e...

Embodiment 3

[0096] Example 3: Another cement-based repair mortar composition formulation:

[0097] This embodiment provides another cement-based repair mortar composition, the composition contains

[0098] 120 parts by weight of cement;

[0099] 120 parts by weight of fine aggregate;

[0100] 20 parts by weight of cement-based repair mortar reinforcing agent described in Example 1;

[0101] Nano-SiO 2 1.5 parts by weight;

[0102] 60 parts by weight of water;

[0103] Waterproofing agent aluminum chloride, the addition amount is 0.01wt% of the cement-based repair mortar composition;

[0104] Stabilizer CaCl 2 , and its addition amount is 0.1 wt% of the cement-based repair mortar composition.

[0105] Redispersible latex powder, the addition amount of which is 0.2wt% of the cement-based repair mortar composition;

[0106] Organosilicon defoamer, the amount of which is 0.12wt% of the cement-based repair mortar composition;

[0107] Wherein, the cement includes 60.0wt% Portland ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com