A high-power heat-resistant explosive

A powerful and heat-resistant technology, applied in explosives, inorganic oxyhalide salt explosive compositions, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve problems such as the application of compounds that have not been seen before, and achieve armor-breaking Increased penetration power, high density, and high detonation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

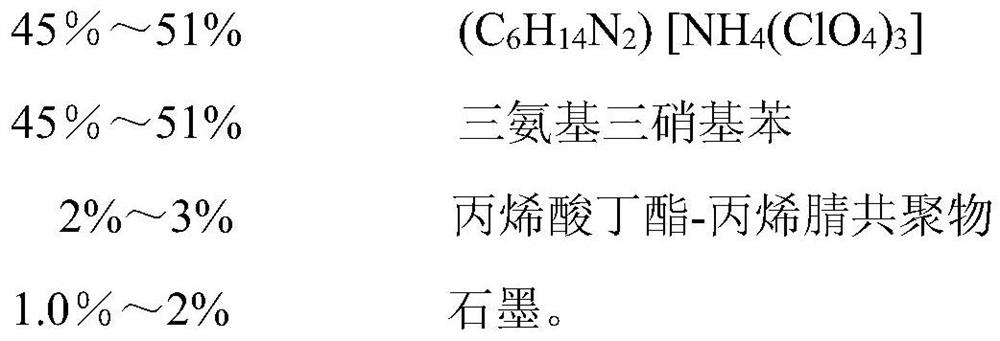

Method used

Image

Examples

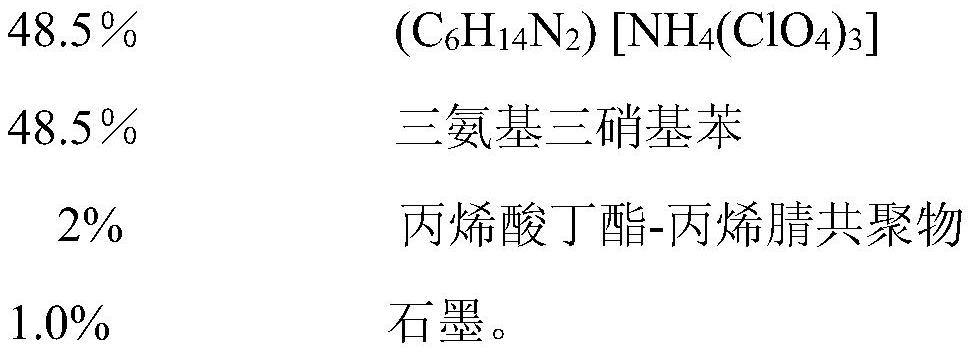

Embodiment 1

[0012] The present embodiment is implemented with reference to the following mass percentage composition: 48.5% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 48.5% triaminotrinitrobenzene, 2% butyl acrylate-acrylonitrile copolymer, 1.0% graphite.

[0013] The preparation of the present embodiment (taking 1000g as an example) method: 485g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] and 485g triaminotrinitrobenzene join in the granulation kettle, and add 200mL ethyl acetate solvent to infiltrate, after mixing, the ethyl acetate solution of 20g butyl acrylate-acrylonitrile copolymer is added in the above-mentioned mixture, Stir for 20 minutes to obtain the mixture; then dry the sample in a water bath oven at 60°C for 4 hours, then collect the sample; weigh the mixed sample, weigh the corresponding amount of graphite according to the graphite ratio of 1.0%, and mix for 10 minutes to obtain a high-power heat-resistant explosives.

Embodiment 2

[0015] The present embodiment is implemented with reference to the following mass percentage composition: 46% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 51% triaminotrinitrobenzene TATB, 2% butyl acrylate-acrylonitrile copolymer, 1.0% graphite.

[0016] The preparation of the present embodiment (taking 1000g as an example) method: 460g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] and 510g triaminotrinitrobenzene join in the granulation kettle, and add 200mL ethyl acetate solvent to infiltrate, after mixing, the ethyl acetate solution of 20g butyl acrylate-acrylonitrile copolymer is added in the above-mentioned mixture, Stir for 20 minutes to obtain the mixture; then dry the sample in a water bath oven at 60°C for 4 hours, then collect the sample; weigh the mixed sample, weigh the corresponding amount of graphite according to the graphite ratio of 1.0%, and mix for 10 minutes to obtain a high-power heat-resistant explosives.

Embodiment 3

[0018] The present embodiment is implemented with reference to the following mass percentage composition: 48.75% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 48.75% triaminotrinitrobenzene, 2% butyl acrylate-acrylonitrile copolymer, 0.5% graphite.

[0019] The preparation of the present embodiment (taking 1000g as an example) method: 487.5g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] and 487.5g of triaminotrinitrobenzene were added to the granulation kettle, and 200mL of ethyl acetate solvent was added for soaking, and after mixing evenly, the ethyl acetate solution of 20g of butyl acrylate-acrylonitrile copolymer was added to the above mixture , and stirred for 20 minutes to obtain the mixture; then the sample was dried in a 60°C water-bath oven for 4 hours, and then the sample was collected; the mixed sample was weighed, and the corresponding amount of graphite was weighed according to the graphite ratio of 0.5%, and mixed for 10 minutes to obtain a high-power resistance hot explosiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com