A cleaning method for aramid 1414 spinneret

A technology of spinneret and aramid fiber, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc. It can solve the problems of poor quality and low efficiency, achieve strong adhesion, high strength, and solve the effect of low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. a cleaning method for aramid fiber 1414 spinneret, is characterized in that, comprises the steps:

[0046] 1) Collection: Use a torque wrench to disassemble the spinneret assembly from the pump base of the metering pump, and remove the spinneret to be cleaned;

[0047] 2) Soaking: Put the spinneret to be cleaned into the stirring device to stir and soak;

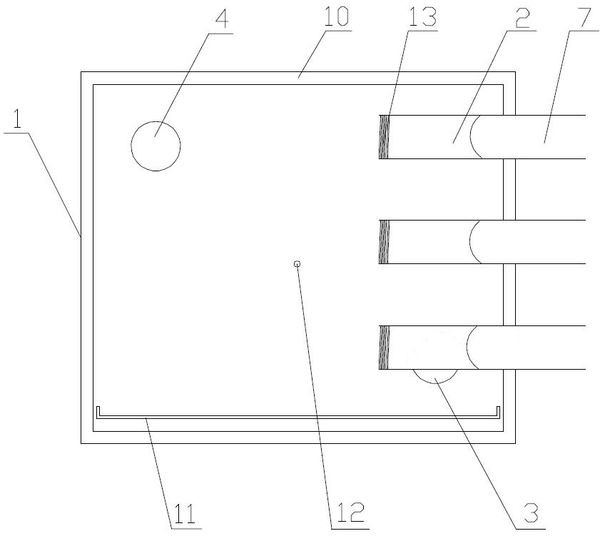

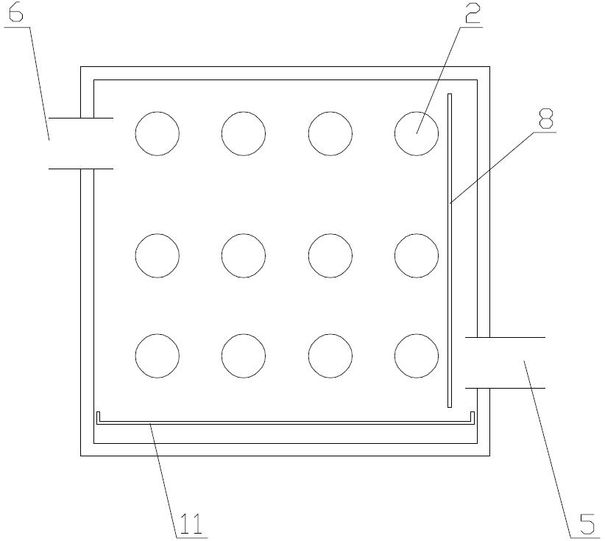

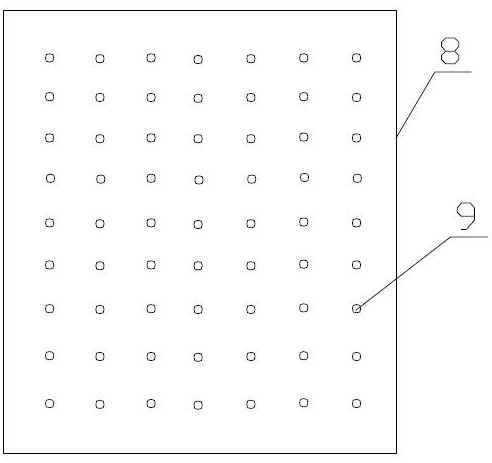

[0048] 3) Heating up and purging: put the spinneret treated in step 2) in the cleaning device, pass hot air through the hot air pipe, and keep warm in the cleaning device; then pass compressed air through the compressed air pipe to spray Wire plate purging;

[0049] 4) Ultrasonic washing: place the spinneret treated in step 3) in an ultrasonic cleaner, and after passing the test, the cleaned spinneret is obtained.

[0050] Among them, soaking and stirring the spinneret makes it easy to clean the slurry; heating and purging, using a cleaning device, heating and purging the spinneret, and efficiently removing the s...

Embodiment 2

[0052] On the basis of embodiment 1, root further,

[0053] In step 2), the stirring refers to stirring for 30 min at a temperature of 40° C. and a rotational speed of 30 r / s.

[0054] In step 3), the temperature of the hot air is 100° C., the holding time is 350 minutes; the pressure of the compressed air is 0.4 Mpa, and the purging time is 4 minutes.

[0055] In step 4), the ultrasonic frequency is 28KHz, and the cleaning time is 30min.

Embodiment 3

[0057] On the basis of embodiment 2, the difference of this embodiment is that

[0058] In step 2), the stirring refers to stirring for 20 min at a temperature of 50° C. and a rotational speed of 40 r / s.

[0059] In step 3), the temperature of the hot air is 180°C, the holding time is 20 minutes; the pressure of the compressed air is 0.8Mpa, and the purging time is 2 minutes.

[0060] In step 4), the ultrasonic frequency is 40KHz, and the cleaning time is 20min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com