Composite fiber containing wheat protein and preparation method thereof

A wheat protein and composite fiber technology, which is applied in the field of composite fiber containing wheat protein and its preparation to achieve the effects of promoting wound healing, brightening and soft, and increasing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

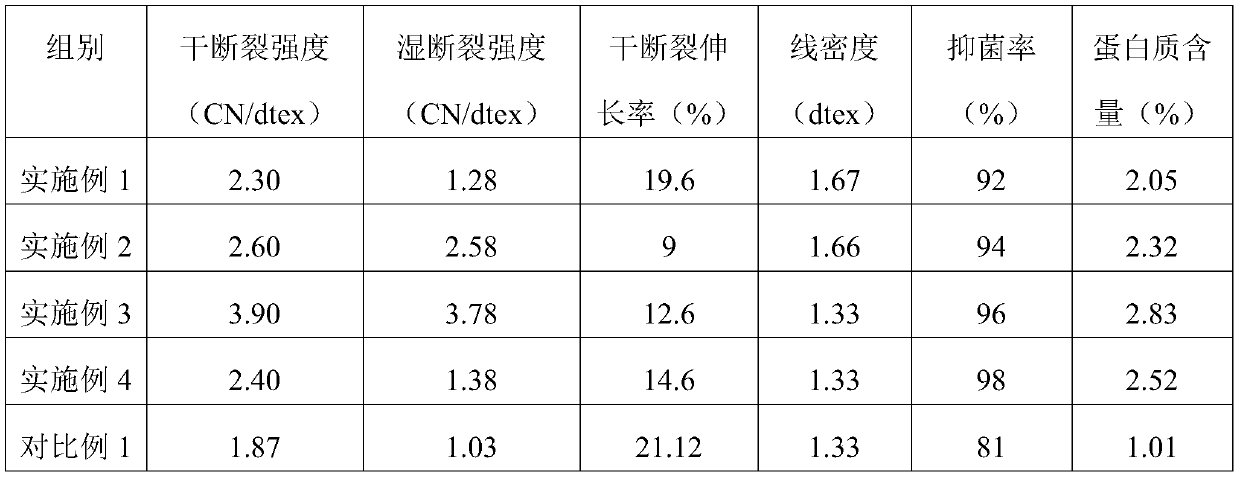

Examples

Embodiment 1

[0041] A kind of preparation method of the composite fiber comprising wheat protein of the present embodiment, comprises the steps:

[0042] First prepare wheat protein solution, the preparation method of wheat protein solution is as follows:

[0043] (a) adding water to the flour to form a dough, proving the dough, washing, stirring to obtain wet gluten, shredding, and drying;

[0044] (b) Grinding the dried gluten, adding it to a hydrochloric acid solution with a pH of 3.5, standing for 45 minutes at a temperature of 68° C., and then centrifuging;

[0045] (c) washing the centrifuged wheat protein in water at 40°C, drying at 65°C, and pulverizing it to a particle size of 1 μm to obtain wheat protein powder;

[0046] (d) immerse the wheat protein micropowder in a 3% NaOH solution with a bath ratio of 1:3, stir evenly at 35°C, centrifuge to take the clear liquid, concentrate and evaporate to obtain a 20% NaOH solution Wheat protein solution.

[0047] The preparation method ...

Embodiment 2

[0052] A kind of preparation method of the composite fiber comprising wheat protein of the present embodiment, comprises the steps:

[0053] First prepare wheat protein solution, the preparation method of wheat protein solution is as follows:

[0054] (a) adding water to the flour to form a dough, proving the dough, washing, stirring to obtain wet gluten, shredding, and drying;

[0055] (b) Grinding the dried gluten, adding it to a hydrochloric acid solution with a pH of 4, standing at a temperature of 70° C. for 50 minutes, and then centrifuging;

[0056] (c) washing the centrifuged wheat protein in water at 45°C, drying at 68°C, and pulverizing it to a particle size of 1.5 μm to obtain wheat protein powder;

[0057] (d) immerse the wheat protein micropowder in a 4% NaOH solution with a bath ratio of 1:3, stir evenly at 40°C, centrifuge to take the clear liquid, concentrate and evaporate to obtain a 20% NaOH solution Wheat protein solution.

[0058] The preparation method ...

Embodiment 3

[0063] A kind of preparation method of the composite fiber comprising wheat protein of the present embodiment, comprises the steps:

[0064] First prepare wheat protein solution, the preparation method of wheat protein solution is as follows:

[0065] (a) adding water to the flour to form a dough, proving the dough, washing, stirring to obtain wet gluten, shredding, and drying;

[0066] (b) Grinding the dried gluten, adding it to a hydrochloric acid solution with a pH of 4.5, standing at a temperature of 72°C for 55 minutes, and then centrifuging;

[0067] (c) washing the centrifuged wheat protein in water at 50° C., drying at 71° C., and crushing to a particle size of 2 μm to obtain wheat protein powder;

[0068] (d) immerse the wheat protein micropowder in a 5% NaOH solution with a bath ratio of 1:3, stir evenly at 45°C, centrifuge to take the clear liquid, concentrate and evaporate to obtain a 20% NaOH solution Wheat protein solution.

[0069] The preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com