Coordinated controllable bubble pump lifting pipe device

A riser and bubble pump technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as high consumption, cumbersome, and complex, and achieve improved performance, broad development, and improved systems. The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

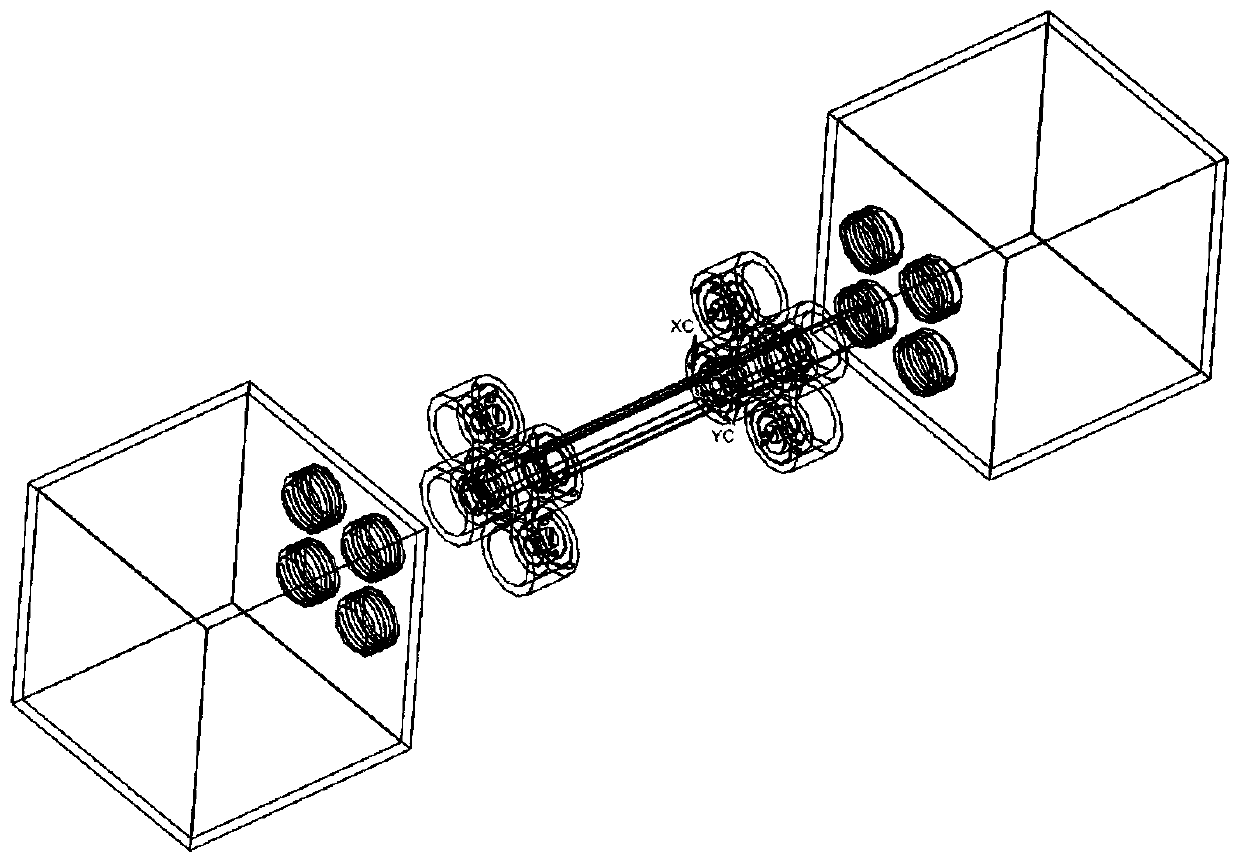

[0035] The riser combination device is a set of devices connected between the bubble generator and the gas-liquid separator. figure 2 An example of adapting a round tube size (outer diameter 19mm) is given. The outer diameter of the part is fixed, and the size of the inner diameter is determined by the outer diameter of the required round tube. Adjust the inner diameter to adapt to different outer diameters. Round tube, the inside of the part is composed of two cylinders with an outer diameter of 22mm and a height of 25mm and a cylinder with an outer diameter of 20mm and a height of 5mm. A gap with a thickness of 1mm is formed between the two for filling and sealing Materials (such as water-swellable water-stop rings resistant to high heat). The upper part of the part is punched, and the special tool is designed to facilitate installation and disassembly. Different round pipe joints are combined with round pipes of different diameters image 3 Tube assembly shown. In the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com