Asphalt mixture rut test piece vibration wheel rolling forming instrument and use method thereof

An asphalt mixture and vibrating wheel technology, applied in the field of construction machinery, can solve the problems of inability to truly reflect on-site road performance, inability to simulate vibration rolling, low density of rutting specimens, etc., so as to achieve easy installation and manufacturing process, and guaranteed use. Longevity, Density Improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

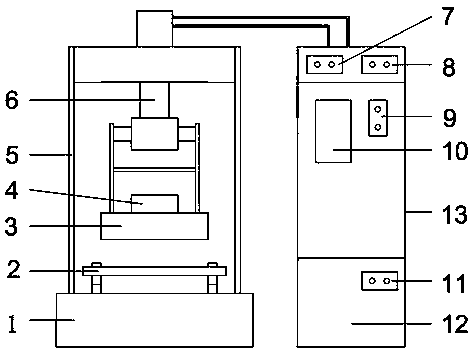

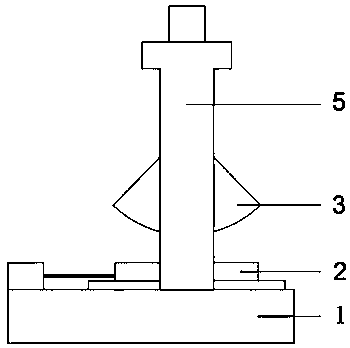

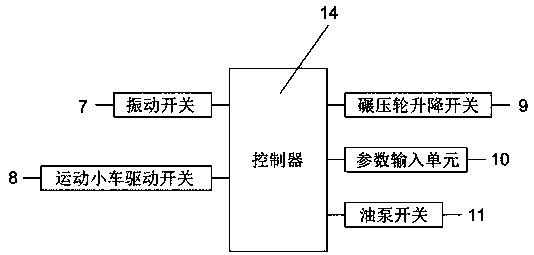

[0025] Embodiment 1: as figure 1 As shown in ~ 3, the asphalt mixture rutting test piece vibratory wheel roller forming apparatus includes a vibratory rolling system and a control system. The vibratory rolling system mainly includes a base 1, a moving trolley 2, a rolling wheel 3 and a vibration motor 4. The base 1. There is a track on the top, and the moving trolley 2 reciprocates on the track. The bottom of the moving trolley 2 is connected to the dowel bar of the driving device. The side of the base 1 is provided with a bracket 5, and the hydraulic dowel 6 is provided with the top of the bracket 5. The rolling wheel 3 is dynamically connected to the hydraulic pressure loading rod of the hydraulic dowel bar 6, and the top of the rolling wheel 3 is provided with a vibrating motor 4; the control system is composed of a box body 13, a vibration switch 7, a motion trolley drive switch 8, and a rolling wheel The lifting switch 9 and the parameter input unit 10 are composed, the h...

Embodiment 2

[0035] Embodiment 2: as Figure 1~3 As shown, the asphalt mixture rutting test piece vibratory wheel roller forming apparatus includes a vibratory rolling system and a control system. The vibratory rolling system mainly includes a base 1, a moving trolley 2, a rolling wheel 3 and a vibrating motor 4. The top of the base 1 There is a track, and the moving trolley 2 reciprocates on the track. The bottom of the moving trolley 2 is connected to the dowel of the driving device. The side of the base 1 is provided with a bracket 5, and the hydraulic dowel 6 is provided with the top of the bracket 5. Rolling The wheel 3 is dynamically connected with the hydraulic pressure loading rod of the hydraulic dowel bar 6, and the top of the rolling wheel 3 is provided with a vibrating motor 4; the control system consists of a box body 13, a vibration switch 7, a moving trolley drive switch 8, and a rolling wheel lift switch. 9 and a parameter input unit 10, the hydraulic pressure loading rod o...

Embodiment 3

[0045] Embodiment 3: as Figure 1~3 As shown, the asphalt mixture rutting test piece vibratory wheel roller forming apparatus includes a vibratory rolling system and a control system. The vibratory rolling system mainly includes a base 1, a moving trolley 2, a rolling wheel 3 and a vibrating motor 4. The top of the base 1 There is a track, and the moving trolley 2 reciprocates on the track. The bottom of the moving trolley 2 is connected to the dowel of the driving device. The side of the base 1 is provided with a bracket 5, and the hydraulic dowel 6 is provided with the top of the bracket 5. Rolling The wheel 3 is dynamically connected with the hydraulic pressure loading rod of the hydraulic dowel bar 6, and the top of the rolling wheel 3 is provided with a vibrating motor 4; the control system consists of a box body 13, a vibration switch 7, a moving trolley drive switch 8, and a rolling wheel lift switch. 9 and a parameter input unit 10, the hydraulic pressure loading rod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com