Method for measuring trap parameters in XLPE cable based on polarizing-depolarizing current test

A technology of current testing and trap parameters, applied in the direction of testing dielectric strength, measuring current/voltage, measuring electricity, etc., can solve problems such as difficult cable size, distinction, and difficulty in ensuring the validity of trap parameter measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] As the experimental sample, 5 circular XLPE sheet samples with a diameter of 10 cm and a thickness of 1 mm were selected. The sample was made by pressing polyethylene particles with a vacuum laminator and cross-linking at 180 °C and 15 Pa for 15 min, and degassed it.

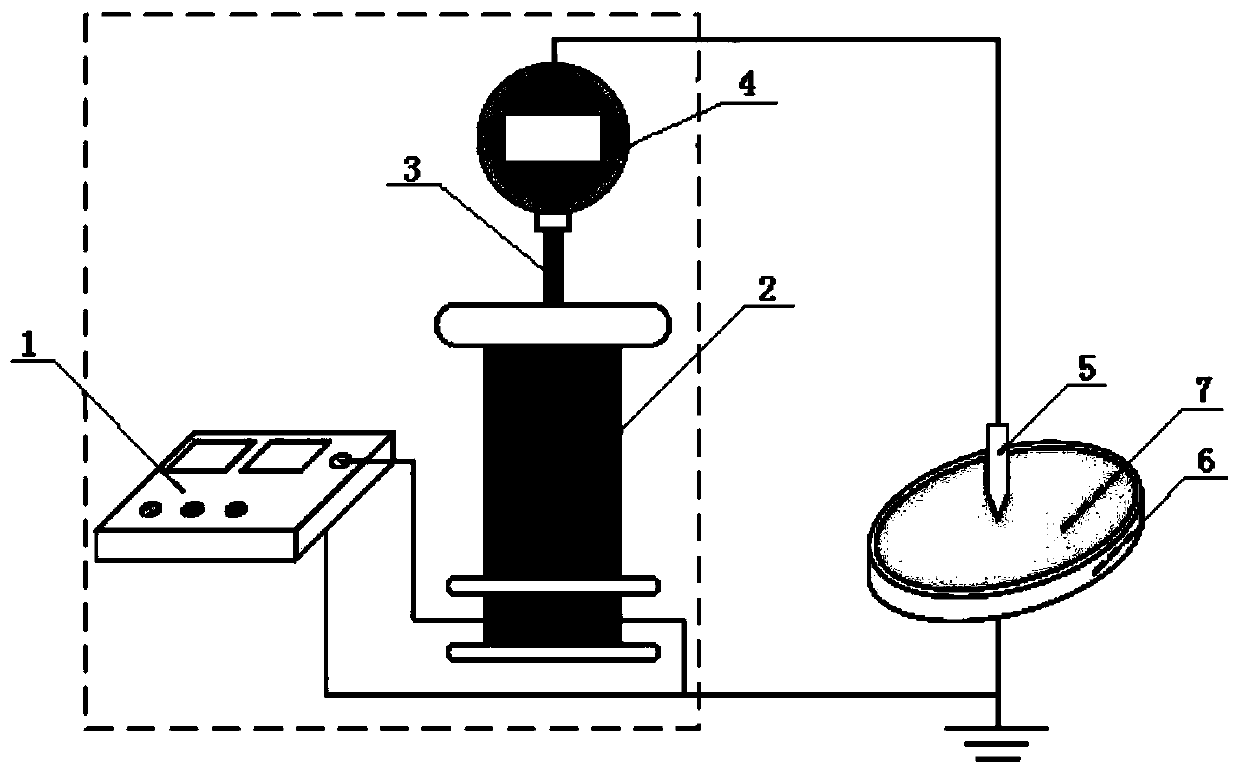

[0049] In this embodiment, the injection method of space charge is the corona injection method, and the experimental principle of space charge injection adopted is as follows: figure 1 As shown, it includes a DC high voltage generator composed of a control box 1, a pressure doubler cylinder 2, a current limiting resistor a3 and a microammeter 4, a needle electrode 5 and a plate electrode 6; the output end of the control box 1 is connected to the pressure doubler cylinder The input end of 2, the high voltage output end of the pressure doubler cylinder are connected in series with the current limiting resistor a3 and the microammeter 4 in sequence, and then connected to the needle electrode 5 through wires,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com