Low-power multi-class motor series experiment platform

An experimental platform and low-power technology, applied in the field of experimental instruments, can solve the problems of inability to observe a variety of motor experimental phenomena, lack of richness in learning and research, and difficult to operate, so as to facilitate research and study, enrich diversity, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

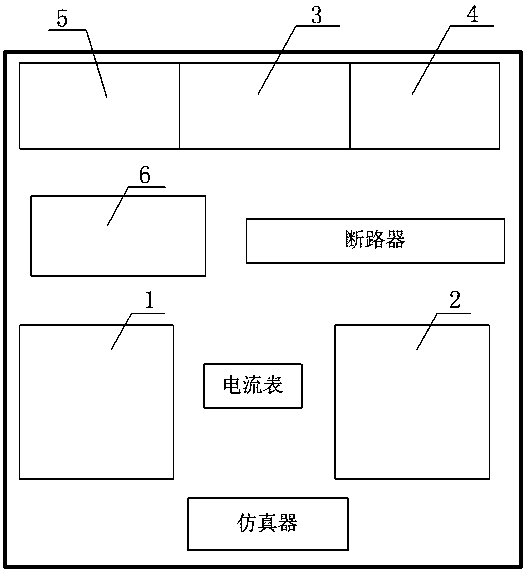

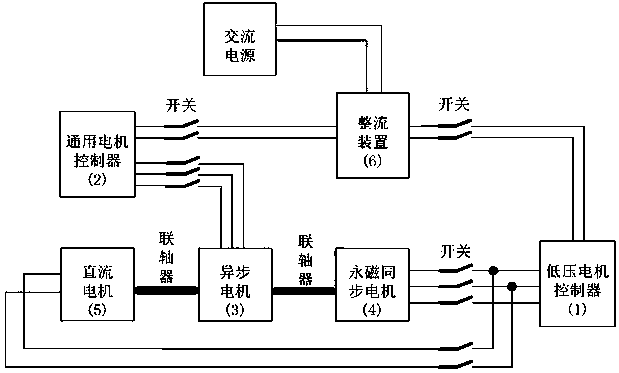

[0012] see figure 1 and figure 2 , the low-power multi-type motor series experiment platform, including low-voltage motor controller (1), general motor controller (2), asynchronous motor (3), permanent magnet synchronous motor (4), DC motor (5), and rectifier device (6). It is characterized in that each component (1, 2, 3, 4, 5, 6) of the experiment platform is fixed on an insulating board.

[0013] The connections between the various components are as follows:

[0014] The low-voltage motor controller (1) is connected to the permanent magnet synchronous motor (4) and the DC motor (5) through a circuit breaker switch; the general motor controller (2) is connected to the asynchronous motor (3) through a circuit breaker switch; the low-voltage motor controller ( 1) Both the universal motor controller (2) are powered by the rectifier (6);

[0015] The shafts of the asynchronous motor (3), the permanent magnet synchronous motor (4) and the DC motor (5) are connected through a...

Embodiment 2

[0018] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0019] The experimental platform is small in size, with a total weight of no more than 12 kg, and has the characteristics of portability. The power supply voltage of the motor controller (1) does not exceed 36V, and has safety features. The power supply voltage of the motor controller (2) does not exceed 400V, and has high voltage characteristics. The multiple types of motors (3, 4, 5) are low-power motors, and the power of each motor does not exceed 90W. The permanent magnet synchronous motor (4) has a photoelectric encoder and a Hall position sensor, and can output an optical encoder signal and a Hall signal. The DC motor (5) has a photoelectric encoder capable of outputting optically encoded signals.

Embodiment 3

[0021] This embodiment is basically the same as Embodiment 1, combining figure 1 The details are as follows:

[0022] exist figure 1 Among them, the low-voltage motor controller (1) and the general motor controller (2) are both composed of a motor drive board and a control board, and the motor drive board and the control board are connected through pins. The low-voltage motor controller (1) is connected with the permanent magnet synchronous motor (4) and the DC motor (5); the general motor controller (2) is connected with the asynchronous motor (3). The low-voltage motor controller (1), the universal motor controller (2), the asynchronous motor (3), the permanent magnet synchronous motor (4), and the DC motor (5) are all powered by the rectifier device (6). One end of the rotating shaft of the asynchronous motor (3) is connected with the rotating shaft of the DC motor (5), and the other end is connected with the permanent magnet synchronous motor (4). The asynchronous motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com